Preparation and use of micron-scale magnetic tweezers

A magnetic tweezers, micron-scale technology, applied in the application of magnetic film to substrate, particle application, nanotechnology, etc., can solve problems such as troublesome production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

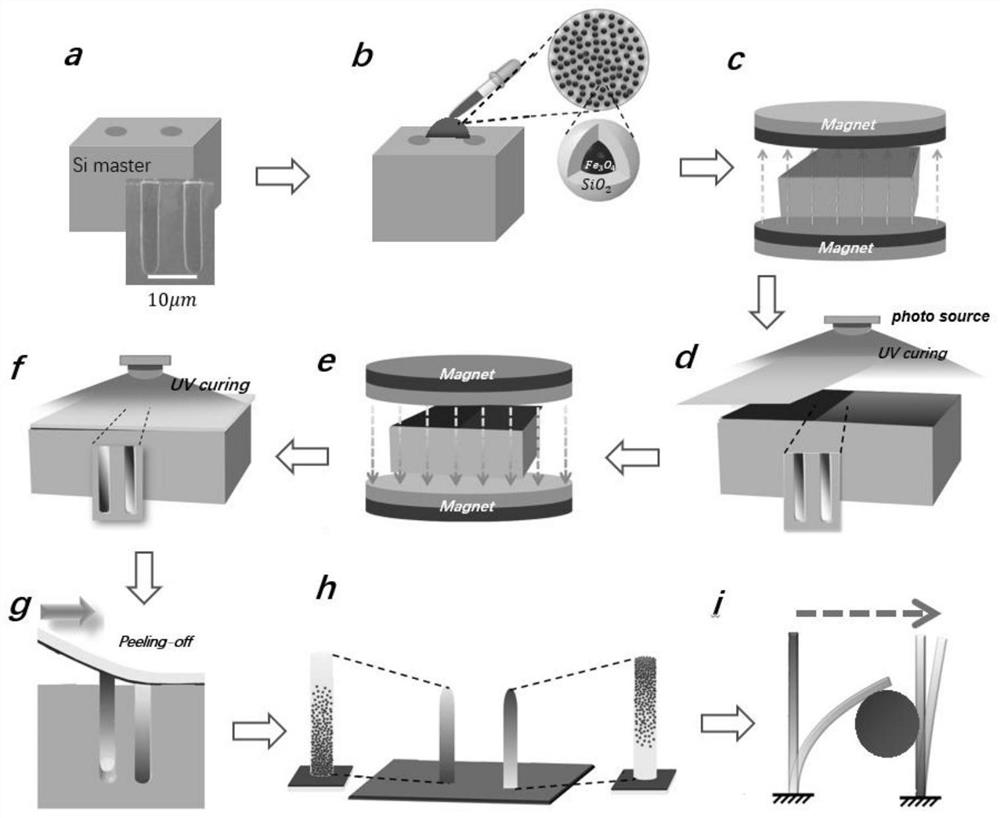

[0035]The preparation and use of micron-scale magnetic forceps in this embodiment, including the following steps:

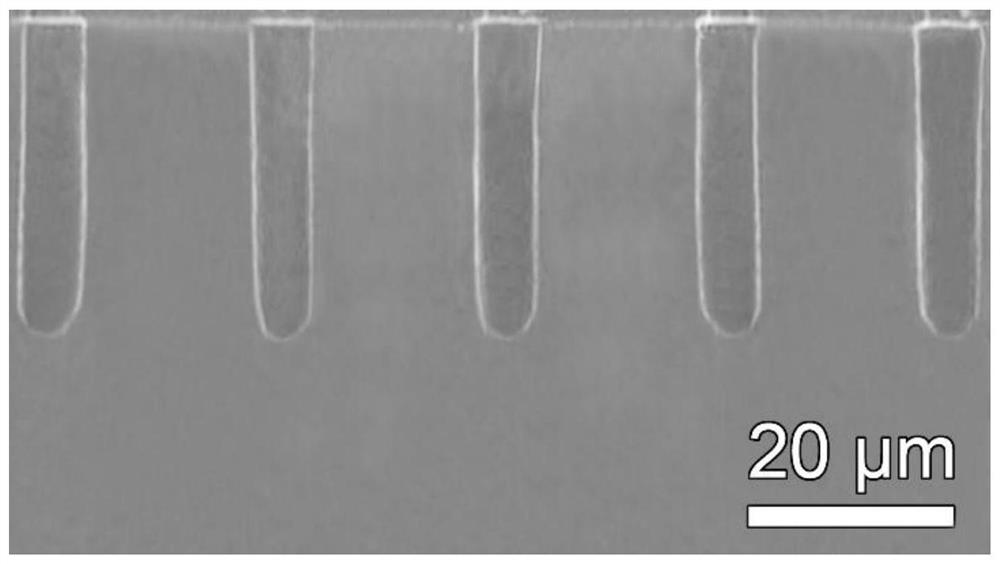

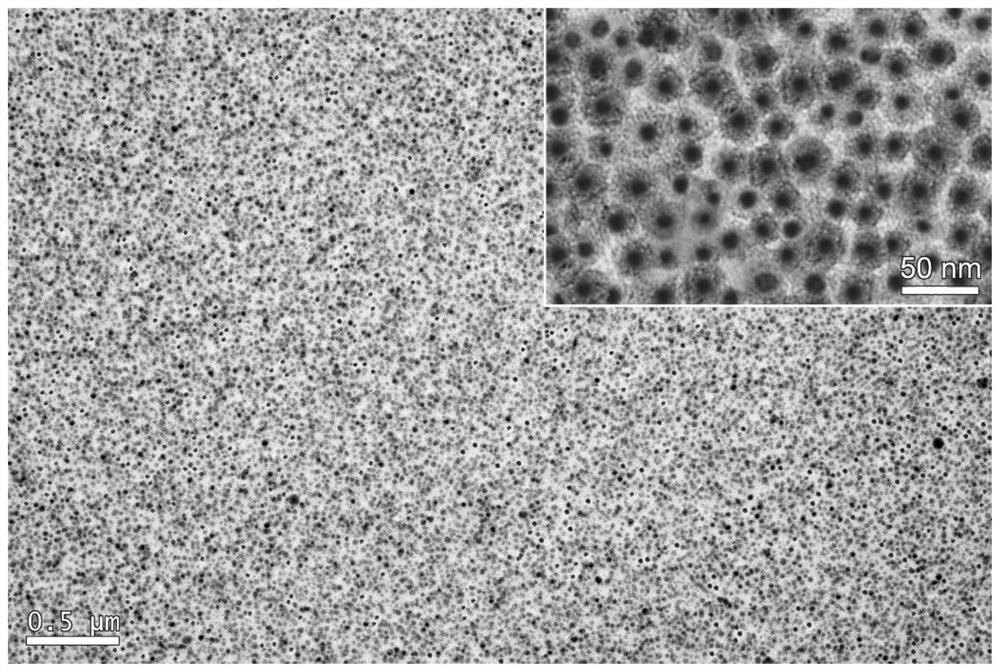

[0036]Step 1: Fill the particles (Non-magnetic substance SiO2Wrap magnetic particles Fe2O3The nanocomposite resin BIS-GMA / TEGDMA (15% filling particle mass fraction is 15%) onto the silicon template substrate, and the liquid assist molding process penetrates into the form of the silicon template substrate to form product I;

[0037]Step 2: Two parallel magnets are placed in the vertical direction of the product I, allowing the product I, the magnetic field in the vertical direction, to reassign the magnetic particles inside the product I to form product II;

[0038]Step 3: Use the photographing to block the silicon template base column, after irradiation with blue light, the photocurable reaction reaction occurs, forming the product III, to obtain a cured microcapsum I;

[0039]Step 4: Switching the two parallel magnets, the product III changes, the magnetic particles in the mag...

Embodiment 2

[0043]Embodiment 2 is the same as that of the first embodiment, and the difference is that the mass fraction of magnetic particles in the mixed solution in step 1 is 10-30%.

Embodiment 3

[0045]Embodiment 3 is the same as the steps of the first embodiment, and the difference is that the magnetic particles in step 1 are Fe, FE2O3, Fe3O4One or more of CO and Ni.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com