Oil field single-pull can well production operation scheduling optimization system and method based on Internet of Things big data

A production operation and big data technology, applied in control/adjustment system, general control system, comprehensive factory control, etc., can solve problems such as wax deposition, wellbore sanding, and large production loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

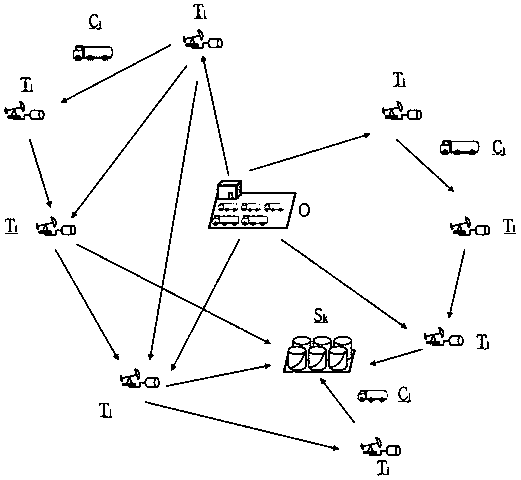

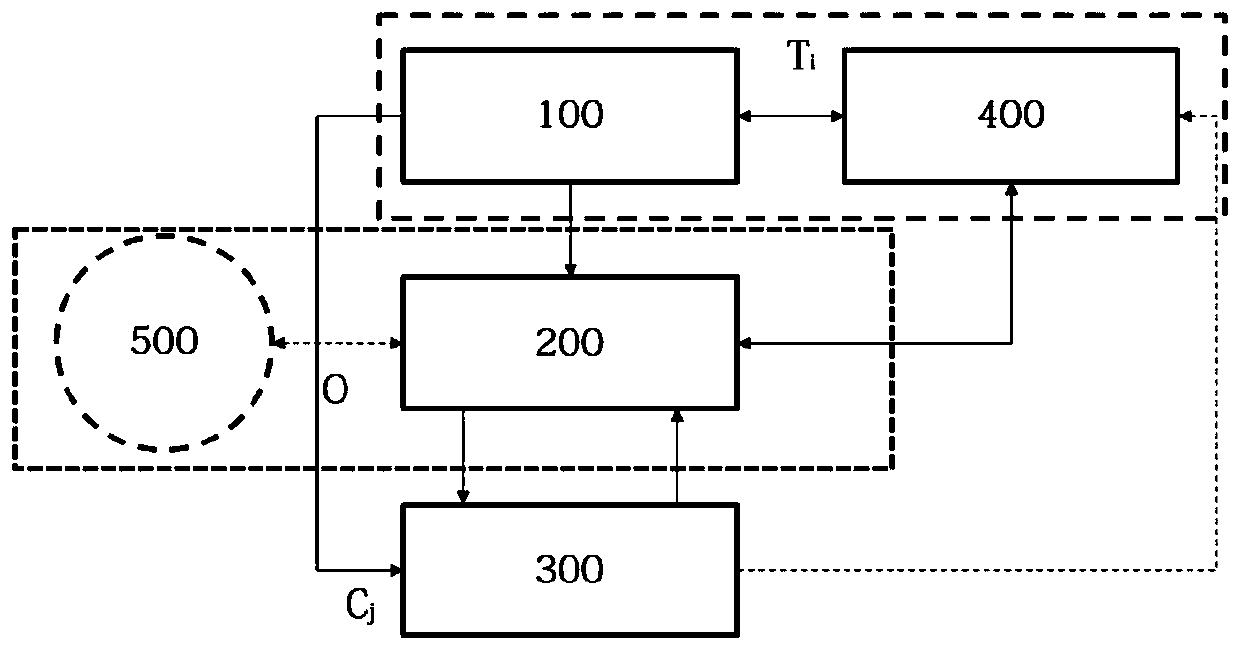

[0026] This embodiment discloses an optimization system for production and operation scheduling of oilfield single-tank wells based on the big data of the Internet of Things. It includes a dispatch terminal 200 , a production sensing module 100 and a vehicle monitoring module 300 .

[0027] The dispatching terminal 200 is independent of the internal network of the oilfield command station and can respectively establish data connections with the production sensing module 100 and the on-board monitoring and monitoring module 300 . The production sensing module 100 and the on-vehicle monitoring module 300 need to use an external network to provide the connection between the dispatch center and each information collector, and the dispatch terminal 200 needs to be connected to the external network. The wireless data transmission in the dispatching terminal 200 and the data transmission of the statistical data of the dispatching terminal 200 to the internal network of the oil field ...

Embodiment 2

[0045] This embodiment discloses an optimization system for production and operation scheduling of oilfield single-tank wells based on the big data of the Internet of Things. This includes a production sensor module 100 , a dispatch terminal 200 and a vehicle monitoring module 300 . Such as figure 2 As mentioned above, the production sensing module 100 is in communication connection with the dispatching terminal 200 . The on-vehicle monitoring and monitoring module 300 communicates with the dispatching terminal 200 . A module in the present invention refers to: hardware, software or a combined data processor capable of executing its related steps.

[0046] The dispatching terminal 200 generates an oil pulling plan based on the intelligent dispatching model based on production parameters, the number of oil trucks pulling oil trucks, fuel load, road conditions, and weather factors. The oil pulling plan is dispatched to the on-board monitoring module 300 of the oil pulling tr...

Embodiment 3

[0057] This embodiment may be a further improvement and / or supplement to Embodiment 1 or 2, and repeated content will not be repeated here. In the case of no conflict or contradiction, the whole and / or part of the content of the preferred implementations of other embodiments may serve as supplements to this embodiment.

[0058]Preferably, the on-board monitoring module 300 is connected with the oil unloading module 400 arranged in the well area through a near field communication module. For example, the on-vehicle monitoring module 300 and the oil unloading module 400 can be connected through Bluetooth, Wifi and the like. The oil unloading module 400 is preferably a smart lock. First, the on-board monitoring module and the oil unloading module can verify each other to ensure that each other's oil unloading work is consistent with the transportation plan. Second, the production parameters can be sent to the dispatching terminal by the on-board monitoring and monitoring module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com