An ultraviolet wide-spectrum lithography lens

A wide-spectrum, ultraviolet light source technology, applied in the field of circuit board lithography, can solve the problem of high cost of use, achieve good stability, easy debugging of the whole machine, and satisfactory imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

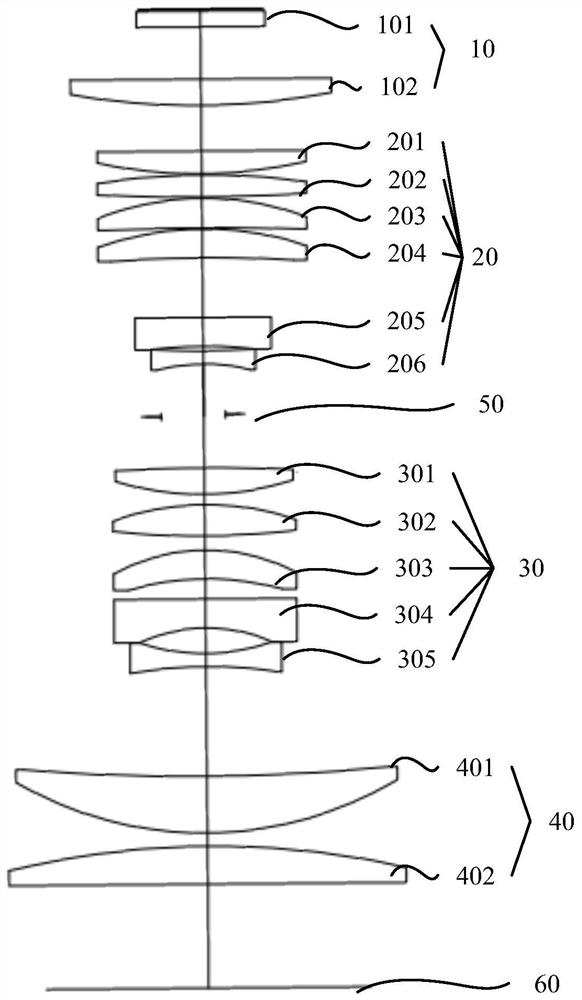

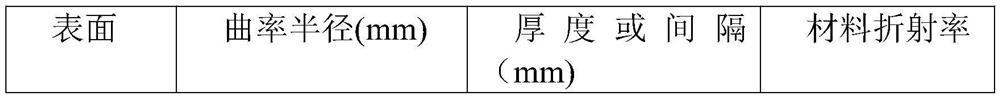

[0126] Table 1 is a summary table of optical parameters of each lens in the lithography lens provided by the embodiment of the present invention, as shown in Table 1,

[0127] Table 1

[0128]

[0129]

[0130] It should be noted that the serial number of each surface is figure 1 The sequence number of each side surface distributed according to the order from the object side of the digital micromirror 101 to the object side of the fourteenth lens 402: for example, S1 is the object side sequence number of the digital micromirror 101; S2 is the number of the first lens 102 The serial number of the object side; S3 is the serial number of the image side of the first lens 102; S4 is the serial number of the object side of the second lens 201; S5 is the serial number of the image side of the second lens 201.

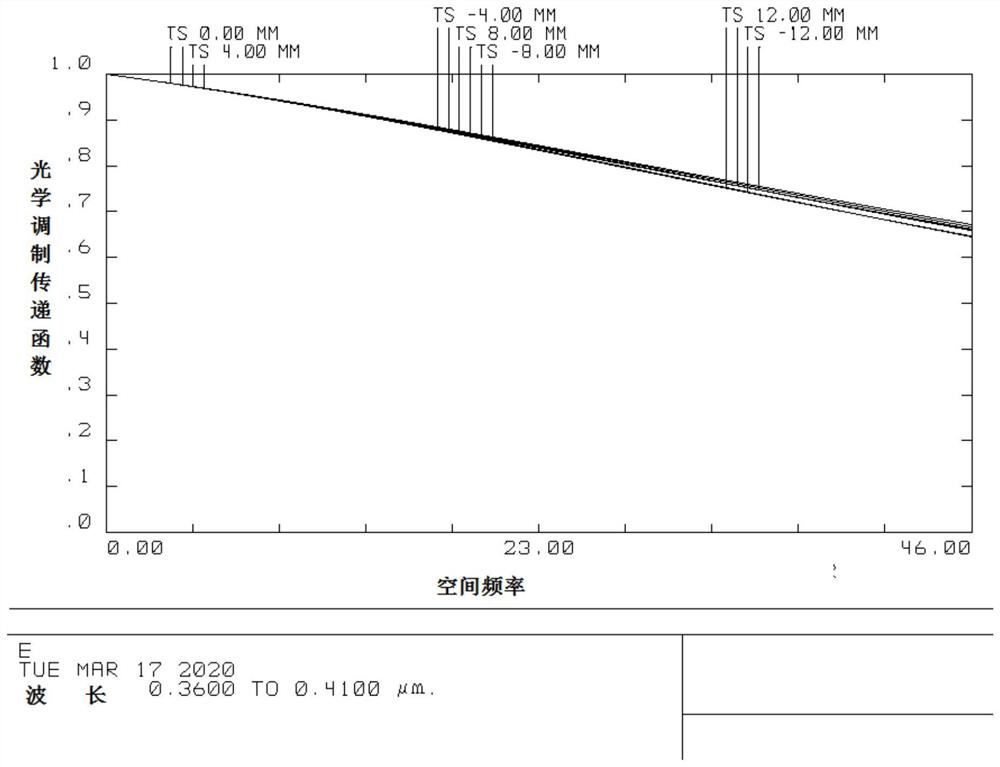

[0131] figure 2 The MTF (ModulationTransfer Function, modulation transfer function) figure of a kind of ultraviolet wide-spectrum lithography lens that the embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com