Two-photon polymerization high-power exposure method and system for galvanometer-assisted cyclic scanning

A technology of two-photon polymerization and auxiliary circulation, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of low two-photon polymerization processing efficiency, achieve high-efficiency mass manufacturing, solve low processing efficiency, high efficiency The effect of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

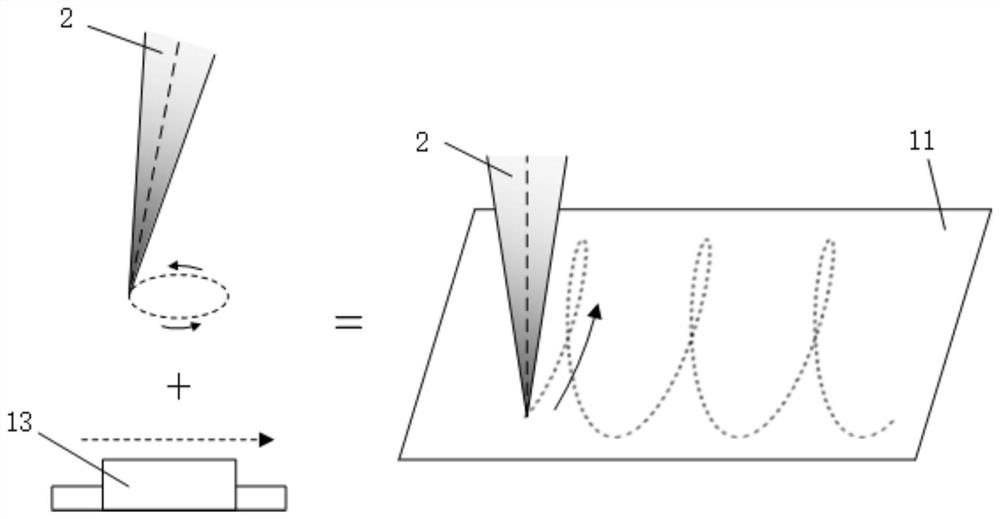

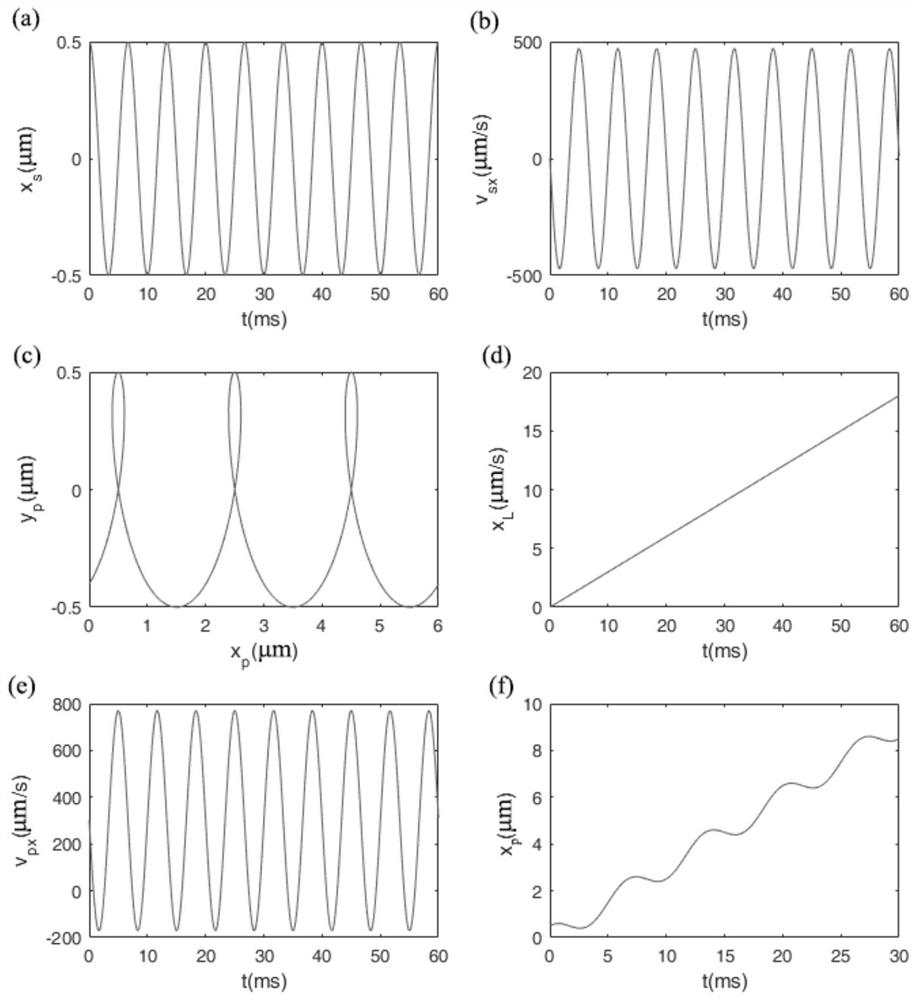

[0045] A two-photon polymerization high-power exposure method for galvanometer-assisted circular scanning, specifically comprising the following steps:

[0046] Step 1: The substrate coated with photoresist is used as the sample 11, placed on the support 10, the illumination source 12 is placed under the sample 11, the support 10 and the illumination source 12 are fixed on the x-direction movement axis 13 by screws On the motion table of the x-direction motion axis 13 is fixed on the motion table of the y-direction motion axis 14; through the output signal of the industrial computer 16, the motion table of the x-direction motion axis 13 and the y-direction motion axis 14 is controlled to drive the sample 11 respectively Moving along the x-direction and y-direction, the two scanning galvanometers 4, the mirror 5, the 4F system 6, the beam splitter 7, the focusing objective lens 9 and the camera 15 are all mounted on the moving platform of the z-direction movement axis 8 by screw...

Embodiment 2

[0078] A two-photon polymerization high-power exposure method for galvanometer-assisted circular scanning, specifically comprising the following steps:

[0079] In step 1, the Ormocer photoresist is coated on the glass substrate as the sample 11, and the bracket 10 has through holes. The sample 11 is placed on the support 10 with the side coated with photoresist facing down. A yellow illuminating light source 12 is placed under the sample 11 . The bracket 10 and the illumination source 12 are fixed on the moving platform of the x-direction moving axis 13 by screws. The x-direction movement axis 13 is fixed on the movement table of the y-direction movement axis 14 . The scanning galvanometer 4, the mirror 5, the 4F system 6, the beam splitter 7, the focusing objective lens 9 and the CCD camera 15 are installed on the moving platform of the z-direction moving axis 8 by screws. Adjust the angle and position of each component so that the laser beam can pass through smoothly. L...

Embodiment 3

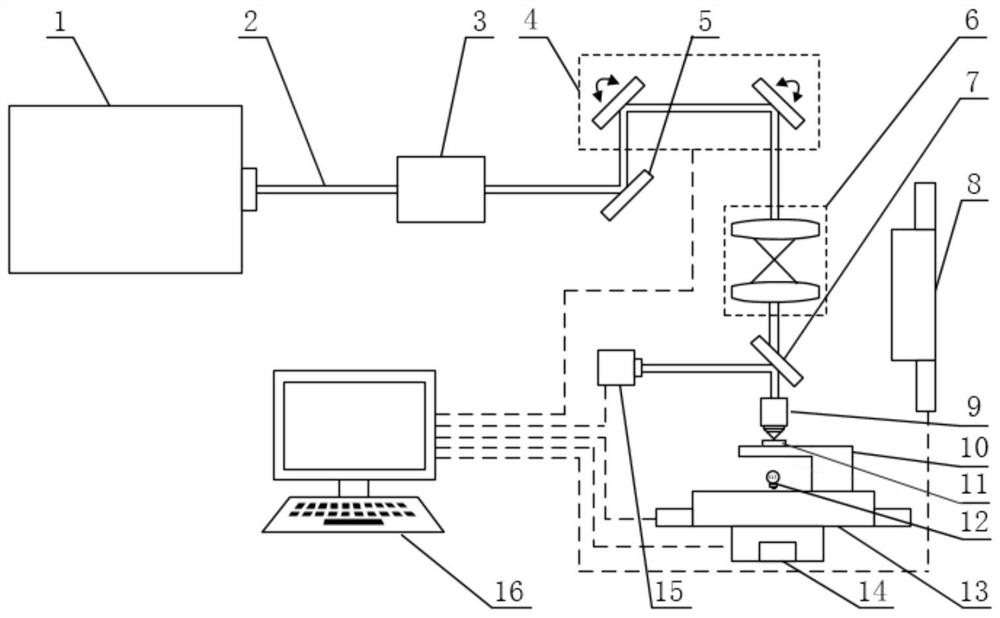

[0096] Such as figure 2 As shown, this embodiment provides a two-photon polymerization high-power exposure system with galvanometer-assisted circular scanning, including a 780nm-800nm wavelength laser 1, a laser beam 2, an optical mirror group 3, a scanning galvanometer 4, a mirror 5, 4F system 6, beam splitter 7, z-direction movement axis 8, focusing objective lens 9, bracket 10, sample 11, 577-597nm yellow illumination source 12, x-direction movement axis 13, y-direction movement axis 14, CCD camera 15 and Industrial computer 16; the laser beam 2 is emitted by the laser 1, attenuated and expanded by the optical mirror group 3, reflected by the reflector 5 and injected into the scanning vibrating mirror 4, passing through the 4F system 6, the beam splitter 7, the focusing Behind the objective lens 9, it focuses on the inside of the sample 11; the sample 11 is placed on the support 10, and the illumination source 12 is placed under the sample 11, and the support 10 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com