Preparation method for nickel hydroxide/polyether amine modified carbon fiber

A nickel hydroxide, carbon fiber technology, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of difficult dispersion and low content of nano-materials, achieve easy industrial production, good repeatability, and increase the reaction between fibers and resins sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Carbon fiber surface cleaning

[0032] Using acetone as a solvent, the long polyacrylonitrile-based carbon fiber tow was condensed and refluxed at 80°C for 48 hours by Soxhlet extraction method, and then dried at 60°C for 4 hours;

[0033] 2) carbon fiber surface oxidation treatment

[0034] Using nitric acid as a solvent, the surface-cleaned carbon fibers were condensed and refluxed at 80°C for 4 hours by Soxhlet extraction, washed with deionized water until the pH of the washed deionized water was 7, and then dried at 60°C for 2 hours to obtain carbon oxide fibers;

[0035] 3) Configuration of deposition solution

[0036] According to the molar ratio of nickel sulfate hexahydrate: potassium persulfate: deionized water = 1:0.18:28, the deposition solution is evenly prepared;

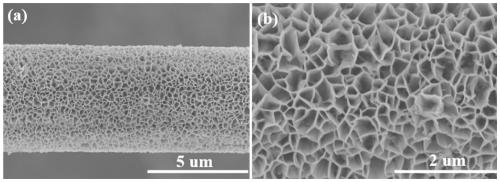

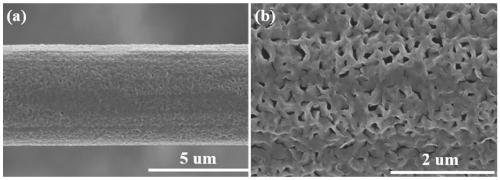

[0037] 4) Preparation of nickel hydroxide coating on carbon fiber surface

[0038] Using the chemical bath deposition method, immerse the carbon oxide fiber prepared in step 2) into a slurr...

Embodiment 2

[0043] 1) Carbon fiber surface cleaning

[0044] Using petroleum ether as a solvent, the carbon fiber cloth was condensed and refluxed at 70°C for 12 hours by Soxhlet extraction, and then dried at 80°C for 2 hours;

[0045] 2) carbon fiber surface oxidation treatment

[0046] Using sulfuric acid as a solvent, the surface-cleaned carbon fibers were condensed and refluxed at 60°C for 6 hours by Soxhlet extraction, washed with deionized water until the pH of the washed deionized water was 7, and then dried at 70°C for 3 hours to obtain carbon oxide fibers;

[0047] 3) Configuration of deposition solution

[0048] According to the molar ratio of nickel sulfate hexahydrate: potassium persulfate: deionized water = 1:0.15:25, the deposition solution is evenly prepared;

[0049] 4) Preparation of nickel hydroxide coating on carbon fiber surface

[0050] Using the chemical bath deposition method, immerse the carbon oxide fiber prepared in step 2) into a slurry tank containing 100ml ...

Embodiment 3

[0054] 1) Carbon fiber surface cleaning

[0055] Using acetone as a solvent, the long polyacrylonitrile-based carbon fiber tow was condensed and refluxed at 80°C for 24 hours by Soxhlet extraction method, and then dried at 70°C for 3 hours;

[0056] 2) carbon fiber surface oxidation treatment

[0057]Using a mixture of nitric acid and sulfuric acid as a solvent, the surface-cleaned carbon fiber was condensed and refluxed at 80°C for 2 hours by Soxhlet extraction, washed with deionized water until the pH of the washed deionized water was 7, and then dried at 50°C for 4 hours Obtain oxidized carbon fiber;

[0058] 3) Configuration of deposition solution

[0059] Prepare a uniform deposition solution according to the molar ratio of nickel sulfate hexahydrate: potassium persulfate: deionized water = 1:0.2:30;

[0060] 4) Preparation of nickel hydroxide coating on carbon fiber surface

[0061] Using the chemical bath deposition method, immerse the carbon oxide fiber prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com