Equipment and method for continuous pickling of titanium and titanium alloy oil pipes

A titanium alloy oil pipe and continuous acid technology, applied in the field of manufacturing, can solve problems such as high safety risks, failure to meet environmental protection requirements, acid liquid or acid mist overflow, etc., to achieve simple equipment structure, ensure quality and size uniformity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

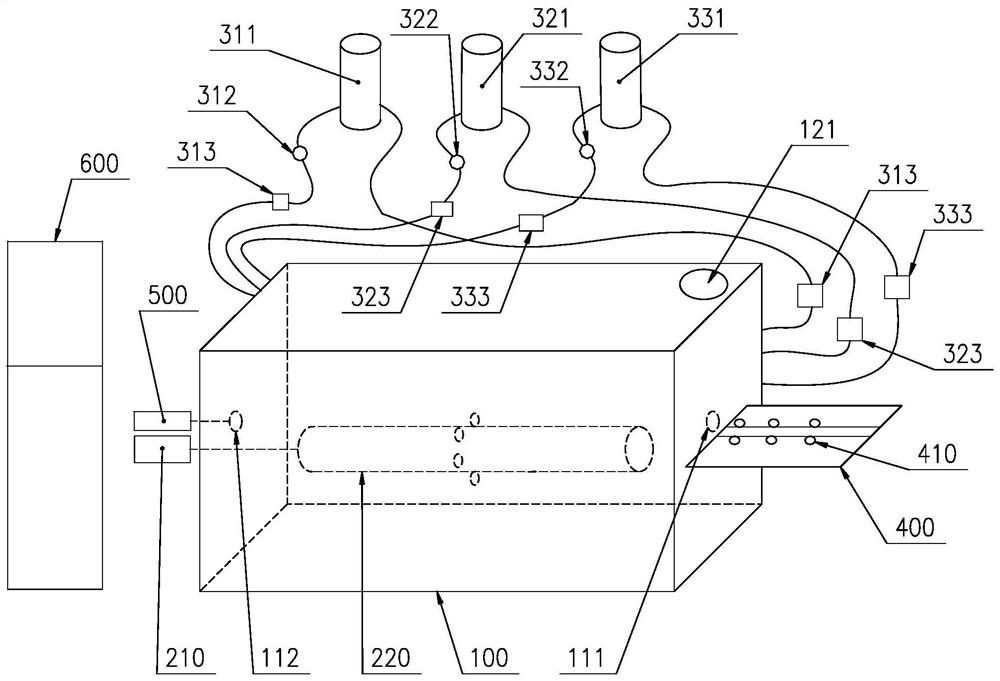

[0055] Equipment for continuous pickling of titanium and titanium alloy oil pipes, including equipment box 100, actuator, circulation mechanism, acid mist collection device and control cabinet 600;

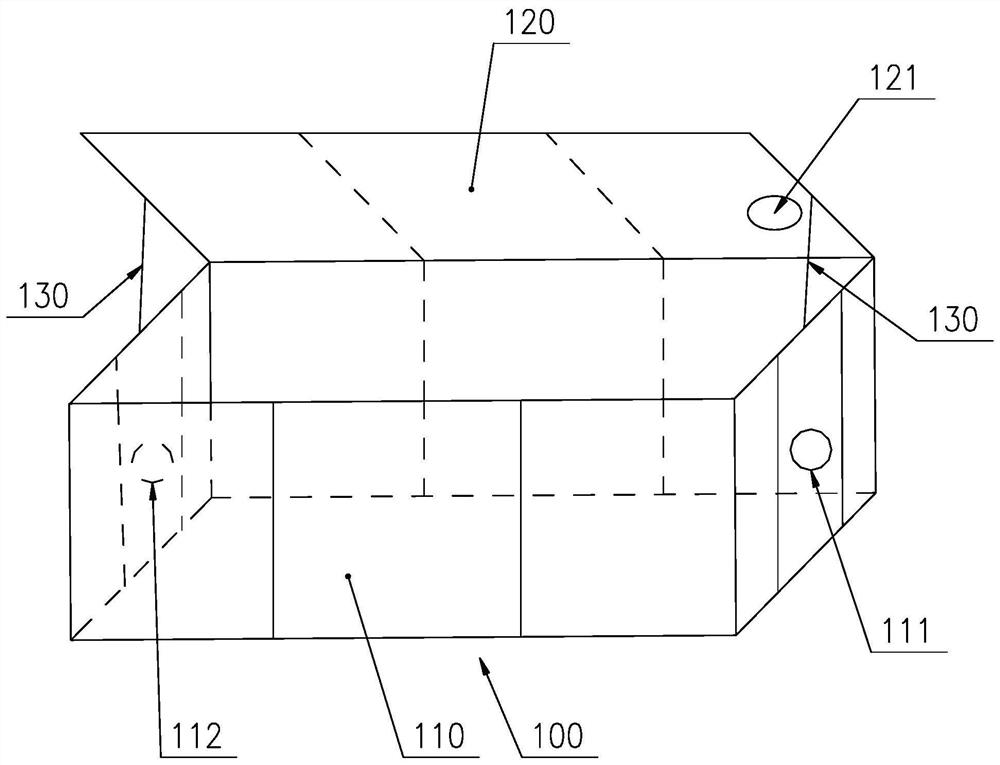

[0056] Equipment box 100 comprises equipment box body 110 and equipment box cover 120, and the top of equipment box body 110 is an opening, and equipment box cover 120 is covered at the top opening of equipment box body 110, and equipment box body 110 is provided with cooling tank, and equipment An acid mist discharge hole 121 is provided on the box cover 120; a support rod 130 is provided between the equipment box cover 120 and the equipment box body 110;

[0057] The equipment box 100 is made of welded PVC plates. The size of the equipment box 110 is 1500mm in length, 400mm in width, 400mm in height, and 10mm in wall thickness. The size of the equipment box cover 120 is 1700mm in length, 400mm in width, and 10mm in thickness. The diameter of 121 is φ100mm;

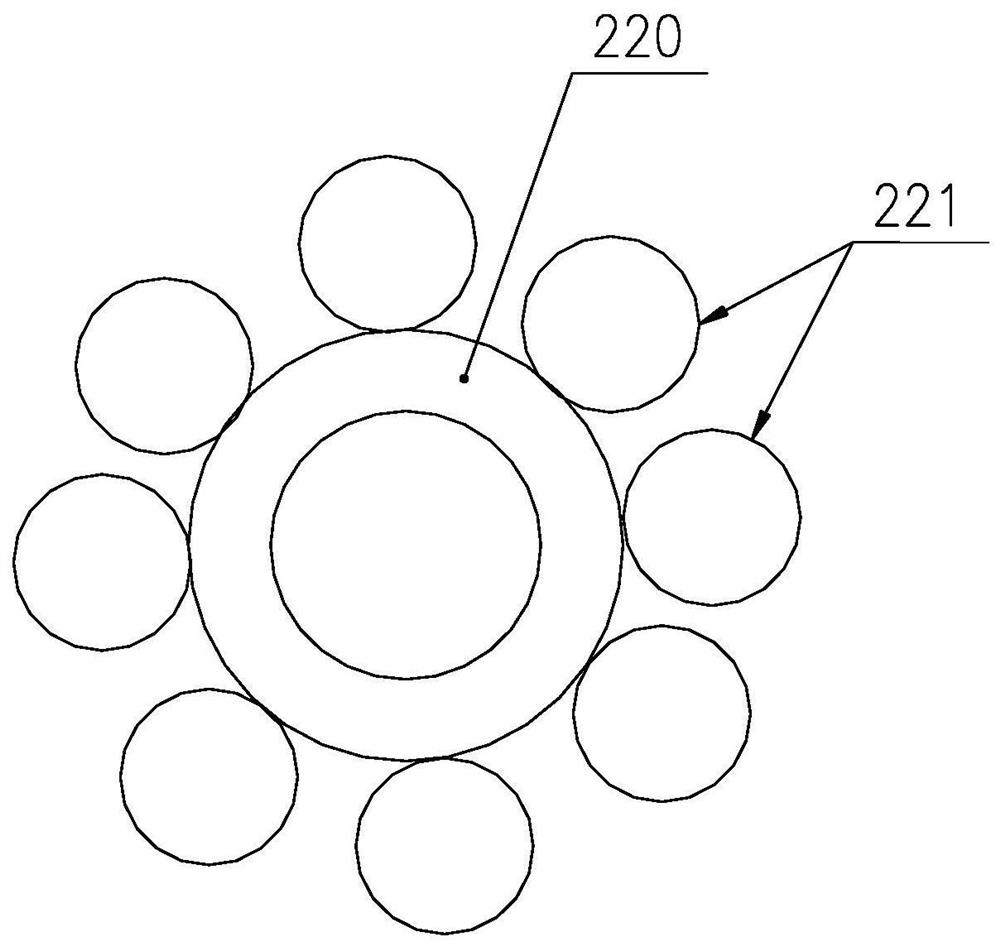

[0058] On the equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com