Efficient anaerobic digestion reactor and use method

An anaerobic digestion and reactor technology, applied in biochemical equipment and methods, gas production bioreactors, solid-phase fermentation bioreactors, etc., can solve problems such as failure to achieve efficient treatment of organic waste, and achieve no fermentation Dead zone, high utilization rate, solid structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

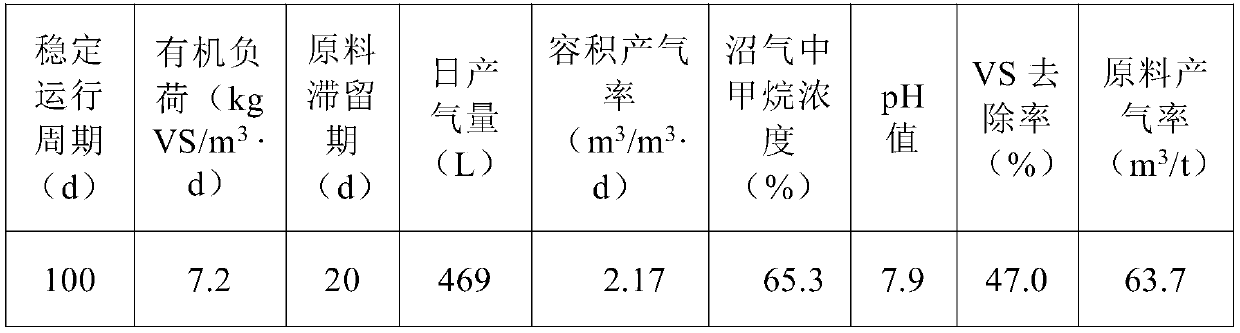

[0060] Continuous anaerobic digestion is carried out with dry pig manure from pig farms as raw material.

[0061] Add the inoculum according to the mass ratio of 10:1, and mix well; the solid content of the inoculum is 20%, and the number of methanogenic bacteria cells is 1.9×10 8 cells / g, the total number of microbial cells shall not be less than 1.2×10 9 pcs / g. The solid content of raw material after inoculation is about 25.5%.

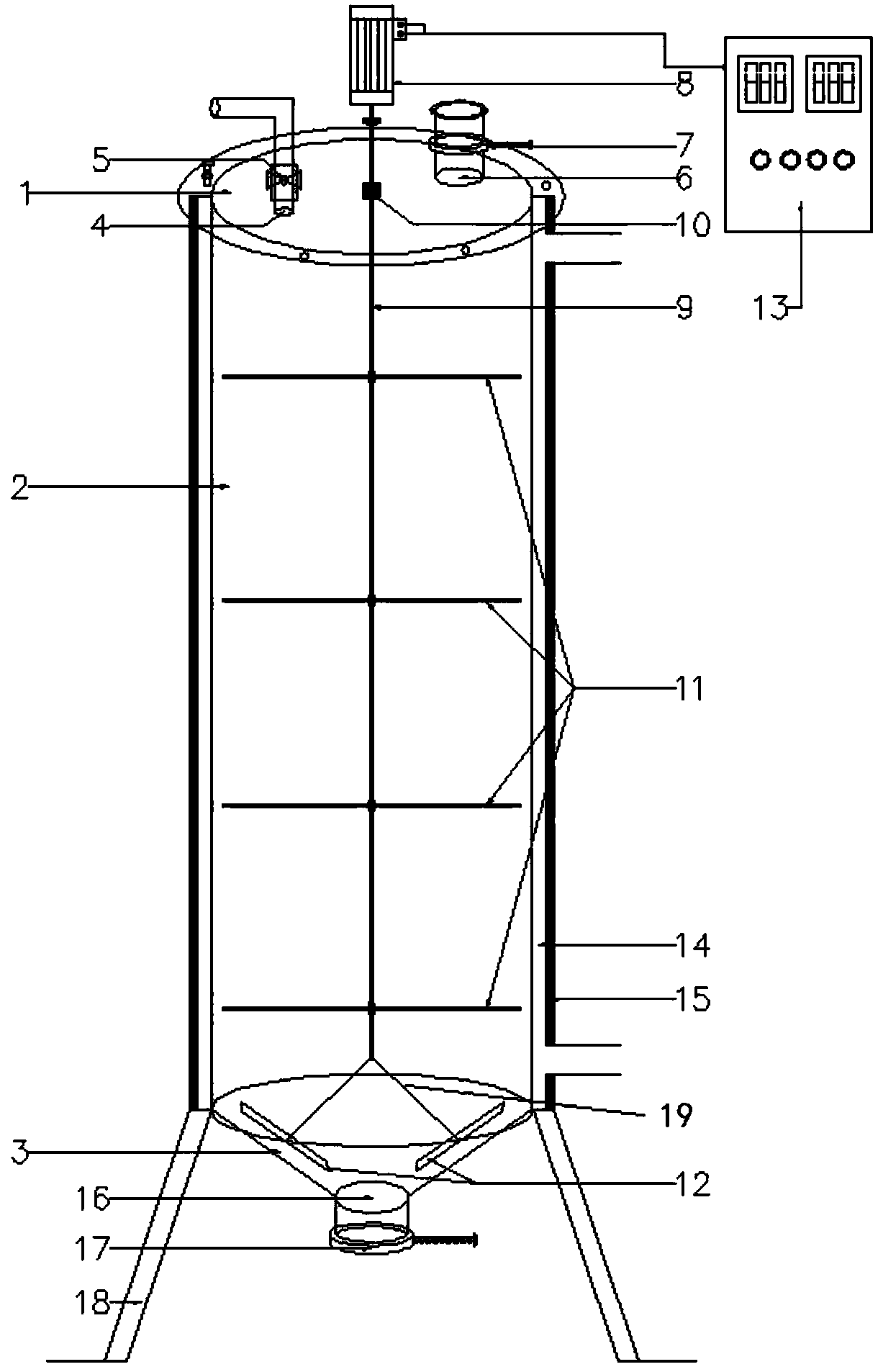

[0062] The high-efficiency anaerobic digestion reactor tank has a diameter of 48cm and a height of 120cm, of which the bottom of the tank is 10cm high, the diameter of the discharge port is 10cm, and the total volume of the reactor is 216L. Add 81 kg of raw materials on the first day of anaerobic digestion, set the temperature of the warming and heat preservation system at 35°C, and set the operating parameters of raw material stirring at 1 time / day, 5 minutes / time, 30 rpm; from the 11th day 8.1kg of raw materials are added every day but no mater...

Embodiment 2

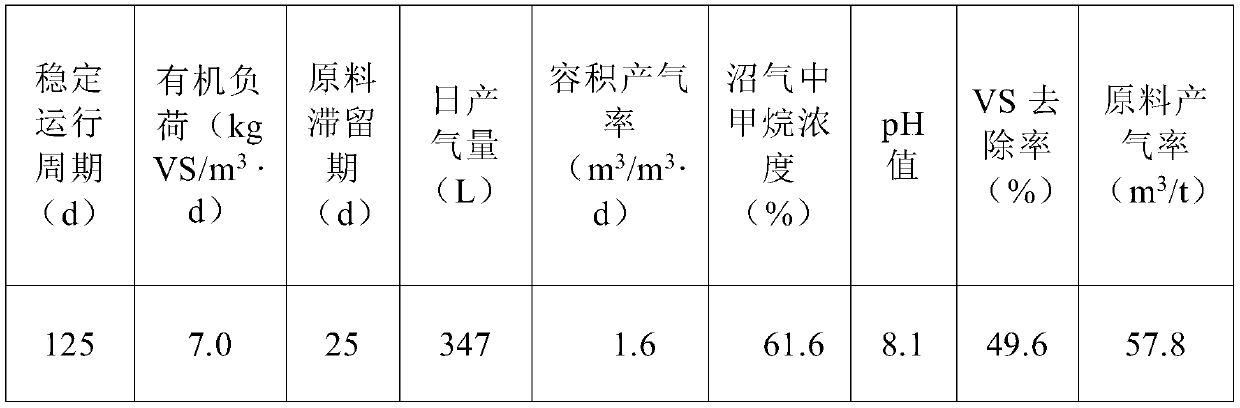

[0069] Continuous anaerobic digestion was carried out with the mixture of chicken manure and air-dried rice straw as raw material.

[0070] First, the air-dried rice straw is pretreated by crushing, and the particle size is about 3 mm. Fully mix chicken manure, pretreated straw, and water at a mass ratio of 4:1:1 to obtain a mixed raw material.

[0071] Then add the inoculum according to the mass ratio of 5:1, and fully mix; the solid content of the inoculum is 18.5%, and the number of methanogenic bacteria cells is 1.3×10 8 cells / g, the total number of microbial cells is 1.1×10 9 pcs / g. The solid content of raw material after inoculation is about 22.3%.

[0072] The high-efficiency anaerobic digestion reactor tank has a diameter of 48cm and a height of 120cm, of which the bottom of the tank is 10cm high, the diameter of the discharge port is 10cm, and the total volume of the reactor is 216L. Add 81kg of raw materials on the first day of anaerobic digestion, set the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com