Preparation method of manganese-arsenic compound

An arsenic compound and manganese powder technology, applied in the fields of manganese compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of restricting the application of manganese arsenic compounds, difficult to control the preparation process, and volatile arsenic element, so as to ensure the arsenic content, High stability and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of manganese arsenic compound, comprising the following steps:

[0037] (1) Under the protection of helium, 150g of manganese powder with a manganese content≥99.9% and a particle size of 100 mesh and 150g of arsenic powder with an arsenic content≥99.999% and a particle size of 150 mesh are mixed in a mixer for 0.5h to obtain Mixture;

[0038] (2) Put the mixture obtained in step (1) into a tube furnace, continuously feed helium, and heat it to 200°C at a heating rate of 5°C / min, keep it warm for 1h, and then heat it at a heating rate of 7°C / min Heating to 450°C, keeping it warm for 5 hours, cooling with the furnace, scraping off the unalloyed part on the surface of the reactant to obtain the manganese-arsenic compound;

[0039] (3) Crushing the manganese-arsenic compound obtained in step (2) into powder, and passing through a 100-mesh sieve to obtain the manganese-arsenic compound powder.

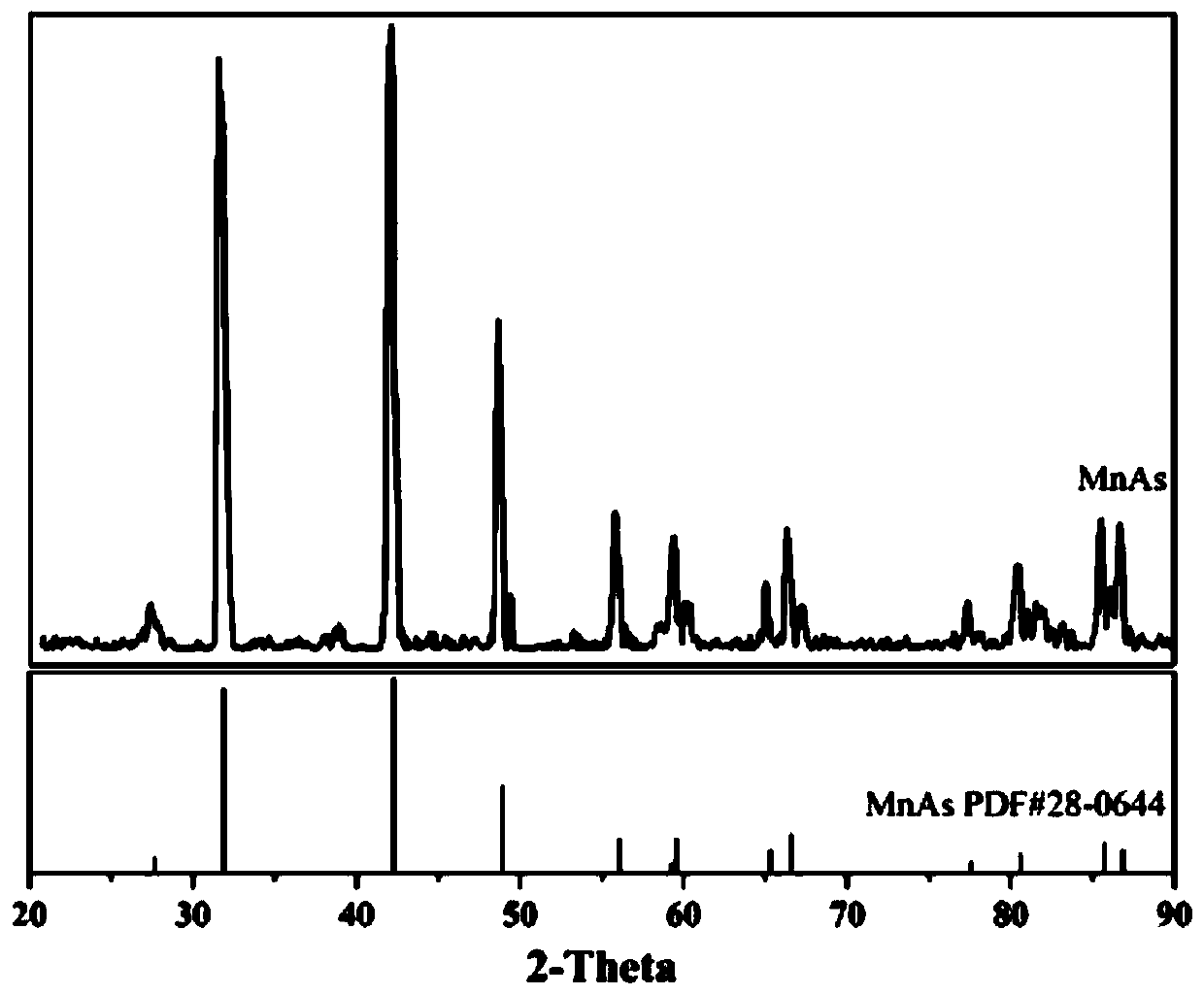

[0040] The X-ray diffraction pattern of the surface layer...

Embodiment 2

[0045] A preparation method of manganese arsenic compound, comprising the following steps:

[0046] (1) Under the protection of nitrogen, mix 150 g of manganese powder with a manganese content ≥ 99.9%, a particle size of 200 mesh, and 120 g of arsenic powder with an arsenic content ≥ 99.999%, and a particle size of 170 mesh in a mixer for 0.8 hours to obtain a mixed material;

[0047](2) Put the mixture obtained in step (1) into a tube furnace, continuously feed nitrogen, and heat to 300°C at a heating rate of 8°C / min, keep it warm for 2 hours, and then heat at a heating rate of 10°C / min To 600 ℃, keep warm for 4 hours, cool with the furnace, scrape off the unalloyed part on the surface of the reactant, and obtain the manganese-arsenic compound;

[0048] (3) Crushing the manganese-arsenic compound obtained in step (2) into powder, passing through a 200-mesh sieve to obtain the manganese-arsenic compound powder.

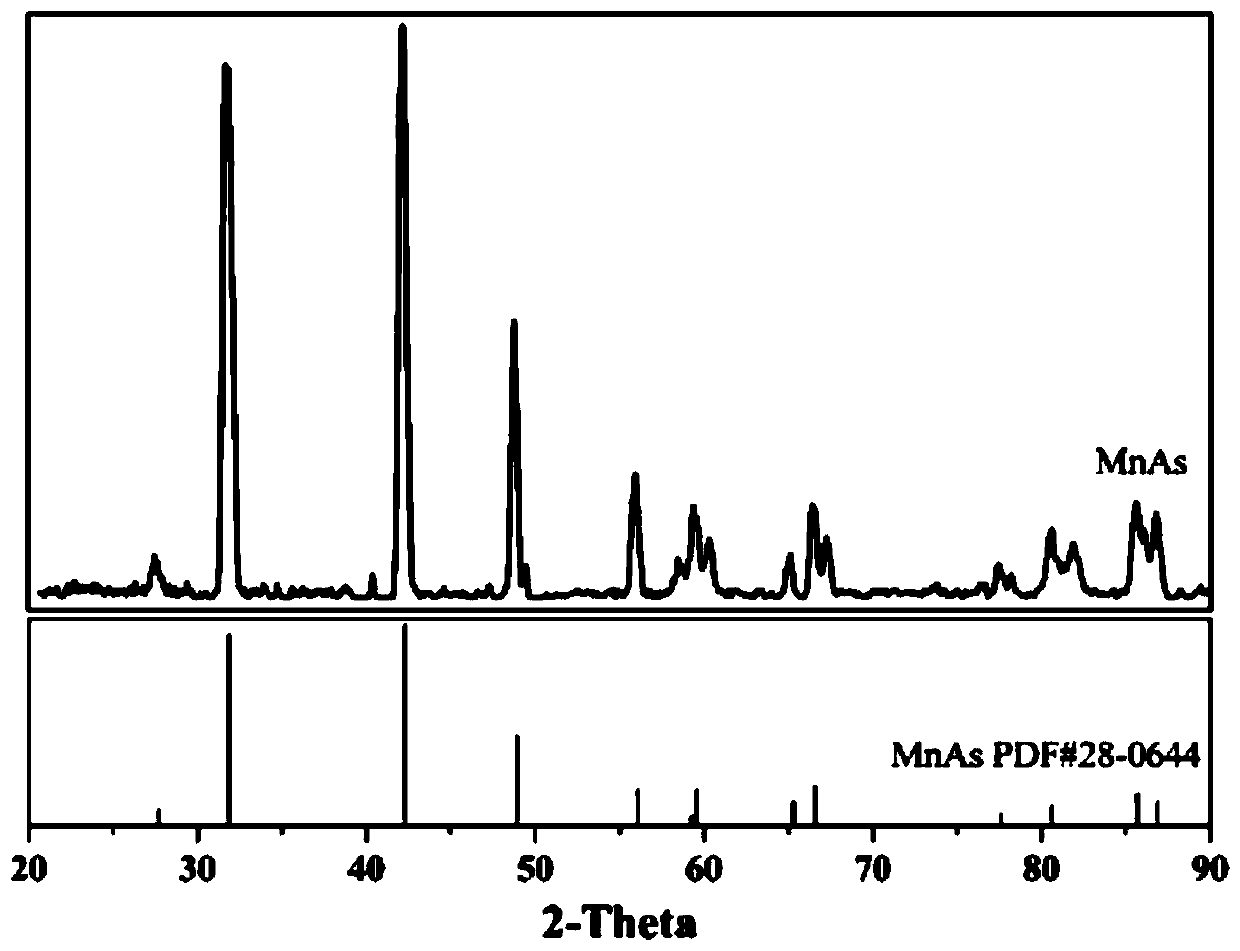

[0049] The X-ray diffraction pattern of the surface layer of t...

Embodiment 3

[0054] A preparation method of manganese arsenic compound, comprising the following steps:

[0055] (1) Under the protection of argon, mix 150 g of manganese powder with a manganese content ≥ 99.9% and a particle size of 325 mesh and 100 g of arsenic powder with an arsenic content ≥ 99.999% and a particle size of 325 mesh in a mixer for 1 hour to obtain a mixture material;

[0056] (2) Put the mixture obtained in step (1) into a tube furnace, continuously feed argon, and heat it to 400°C at a heating rate of 10°C / min, keep it warm for 3h, and then heat it at a heating rate of 15°C / min Heating to 800°C, keeping it warm for 3 hours, cooling with the furnace, scraping off the unalloyed part on the surface of the reactant to obtain the manganese-arsenic compound;

[0057] (3) Crushing the manganese-arsenic compound obtained in step (2) into powder, and passing through a 325-mesh sieve to obtain the manganese-arsenic compound powder.

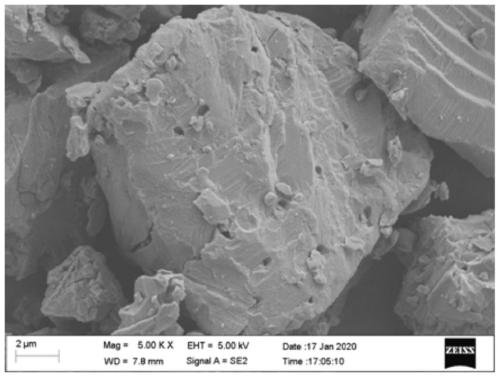

[0058] The X-ray diffraction pattern of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com