Flame-retardant heat-insulation straw color steel plate and preparation method and application thereof

A color steel plate and straw technology, applied in chemical instruments and methods, lamination, anti-corrosion coatings, etc., can solve the problems of poor flame retardancy, poor mechanical properties, poor water resistance, etc., and achieve good structural stability, low cost, and thermal insulation. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

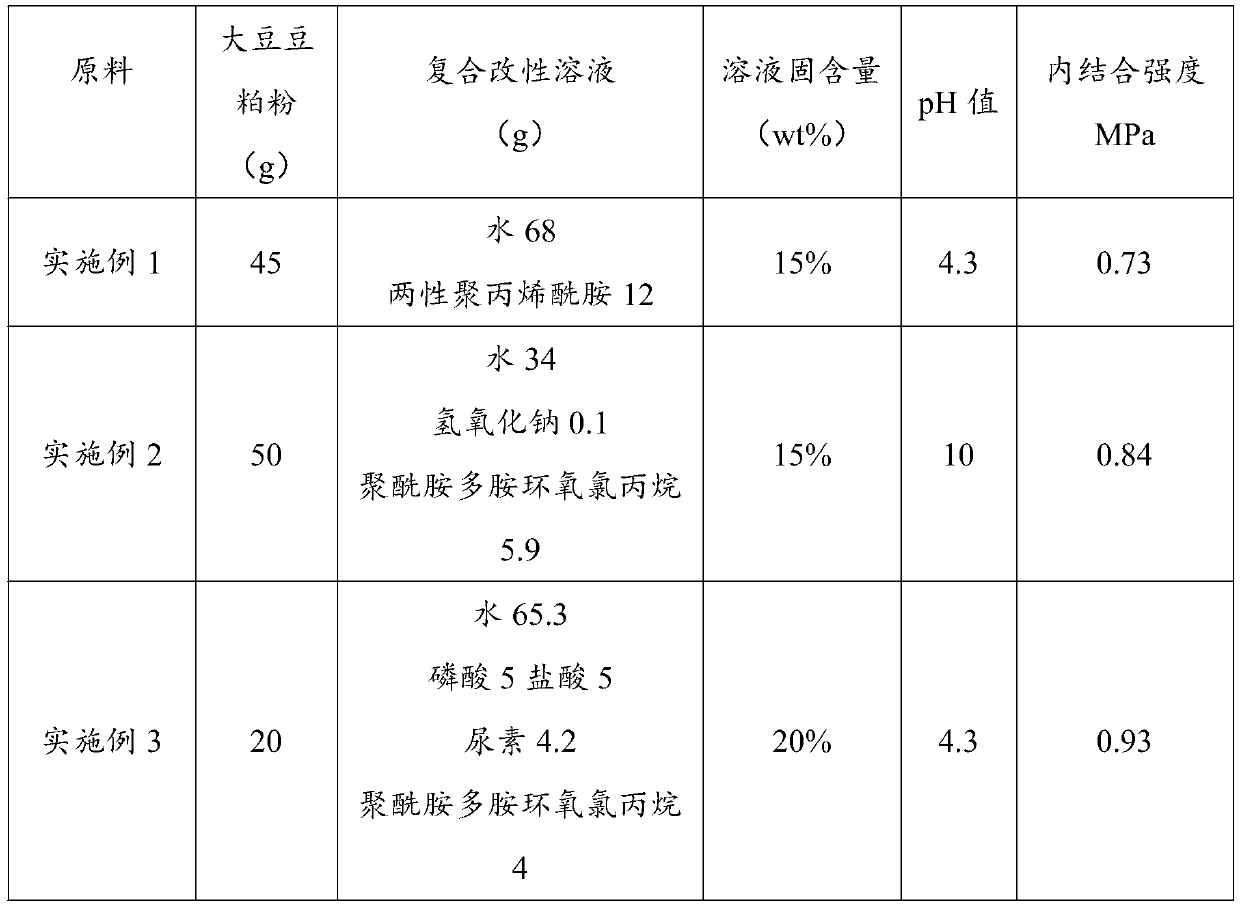

Embodiment 1

[0023] A flame-retardant heat-insulating straw color steel plate, the flame-retardant heat-insulation straw color steel plate is composed of a base plate steel, a straw core and a paint layer, the base plate steel is a deep-drawn thin steel plate, and the raw material of the straw core is The ratio of parts is: 40-80 parts of straw, 1-2 parts of filler, 4-6 parts of weather resistance agent, 5-15 parts of two-component soybean meal protein-based adhesive; the two-component soybean meal protein-based adhesive The ratio of the raw materials is as follows: 20-30 parts of soybean meal powder and 30-100 parts of compound modification solution.

[0024] The preparation method of flame-retardant and heat-insulating straw color steel plate includes the following steps: the first step: take dry and clean straw and transport it to the feeder through a conveying and screening device. During the conveying process, the straw is first conveyed horizontally The straw is transported to the in...

Embodiment 2

[0033] A flame-retardant heat-insulating straw color steel plate, the flame-retardant heat-insulation straw color steel plate is composed of a base plate steel, a straw core and a paint layer, the base plate steel is a deep-drawn thin steel plate, and the raw material of the straw core is The ratio of parts is: 40-80 parts of straw, 1-2 parts of filler, 4-6 parts of weather resistance agent, 5-15 parts of two-component soybean meal protein-based adhesive; the two-component soybean meal protein-based adhesive The ratio of the raw materials is as follows: 20-30 parts of soybean meal powder and 30-100 parts of compound modification solution.

[0034] The preparation method of flame-retardant and heat-insulating straw color steel plate includes the following steps: the first step: take dry and clean straw and transport it to the feeder through a conveying and screening device. During the conveying process, the straw is first conveyed horizontally The straw is transported to the in...

Embodiment 3

[0043] A flame-retardant heat-insulating straw color steel plate, the flame-retardant heat-insulation straw color steel plate is composed of a base plate steel, a straw core and a paint layer, the base plate steel is a deep-drawn thin steel plate, and the raw material of the straw core is The ratio of parts is: 40-80 parts of straw, 1-2 parts of filler, 4-6 parts of weather resistance agent, 5-15 parts of two-component soybean meal protein-based adhesive; the two-component soybean meal protein-based adhesive The ratio of the raw materials is as follows: 20-30 parts of soybean meal powder and 30-100 parts of compound modification solution.

[0044] The preparation method of flame-retardant and heat-insulating straw color steel plate includes the following steps: the first step: take dry and clean straw and transport it to the feeder through a conveying and screening device. During the conveying process, the straw is first conveyed horizontally The straw is transported to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com