Method for preparing high-precision small-caliber TA2 pipe for spaceflight

A high-precision, small-caliber technology, used in manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of poor surface quality of pipes, unqualified test results, and incomplete elimination of internal stress, and achieve dimensional accuracy and Performance requirements, small and uniform material structure, and the effect of increasing the intermediate annealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

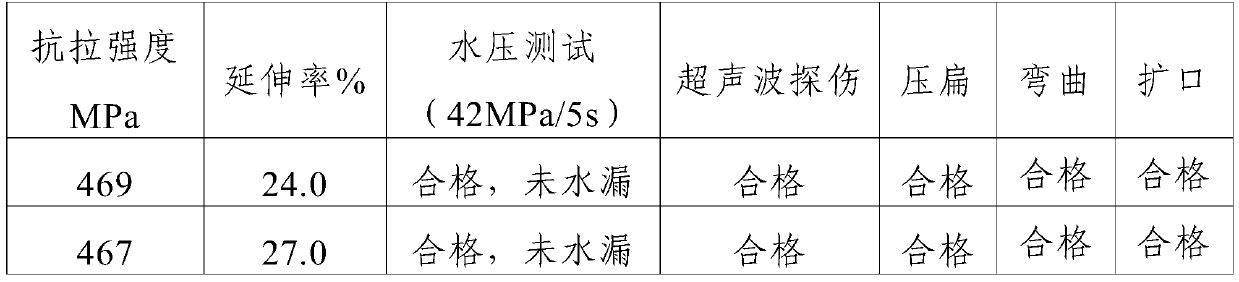

Embodiment 1

[0023] Preparation specifications of this embodiment High-precision small-diameter TA2 pipes, the method specifically includes the following steps:

[0024] Step 1. Saw and cut the TA2 bar with a specification of Φ64mm×L according to the length of 200mm to 240mm to obtain a billet. Use a lathe to peel and drill the billet to obtain a hollow tube blank. The size of the tube blank after machining is Bar billet inner hole, outer circle chamfer (3~4)mm×45°;

[0025] Step 2. Hot-extrude the hollow tube blank in step 1, extrusion cylinder Φ65mm, extrusion die Φ22mm ±0.2 mm, extrusion needle 13 ±0.2 mm, extrusion speed 90mm / s, billet heating temperature 750°C, after extrusion, the pipe billet is straightened with residual heat until it rolls smoothly on the horizontal plane, and the specification of the pipe billet after extrusion is Φ22 ±0.2 ×4.5 ±0.2 mm;

[0026] Step 3. Surface treatment is carried out on the tube blank extruded in step 2 to remove the surface scale and res...

Embodiment 2

[0036] Preparation specifications of this embodiment High-precision small-diameter TA2 pipes, the method specifically includes the following steps:

[0037] Step 1. Saw and cut the TA2 bar with a specification of Φ64mm×L according to the length of 200mm to 240mm to obtain a billet. Use a lathe to peel and drill the billet to obtain a hollow tube blank. The size of the tube blank after machining is Both the inner hole and the outer round chamfer of the billet are (3~4)mm×45°;

[0038] Step 2. Hot-extrude the hollow tube blank in step 1, extrusion cylinder Φ65mm, extrusion die Φ22mm ±0.2 mm, extrusion needle 13 ±0.2 mm, extrusion speed 80mm / s, billet heating temperature 730°C, after extrusion, the pipe billet is straightened with waste heat until the horizontal plane rolls smoothly, and the pipe billet after extrusion has a specification of Φ22 ±0.2 ×4.5±0.2 mm;

[0039] Step 3. Surface treatment is carried out on the tube blank extruded in step 2 to remove the surface sca...

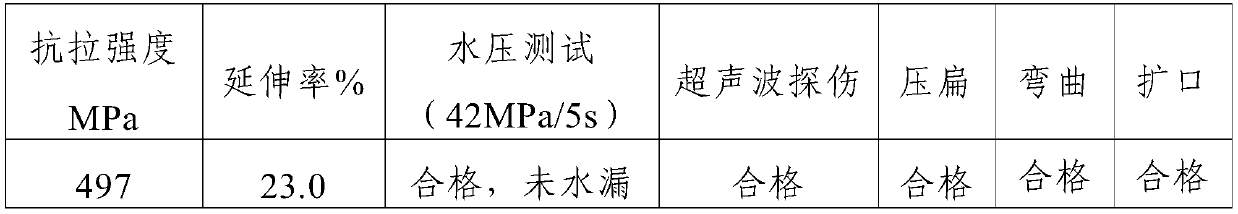

Embodiment 3

[0050] Preparation specifications of this embodiment High-precision small-diameter TA2 pipes, the method specifically includes the following steps:

[0051] Step 1. Saw and cut the TA2 titanium rod with a specification of Φ64mm×L according to the material length of 200mm to 240mm to obtain a billet. Use a lathe to peel and drill the billet to obtain a hollow tube blank. The size of the tube blank after machining is Both the inner hole and the outer round chamfer of the billet are (3~4)mm×45°;

[0052] Step 2. Hot-extrude the hollow tube blank in step 1, extrusion cylinder Φ65mm, extrusion die Φ22mm ±0.2 mm, extrusion needle 13 ±0.2 mm, extrusion speed 100mm / s, ingot heating temperature 770°C, after extrusion, the tube blank is straightened with waste heat until it rolls smoothly on the horizontal plane, and the specification of the tube blank after extrusion is Φ22 ±0.2 ×4.5 ±0.2 mm;

[0053] Step 3. Surface treatment is carried out on the tube blank extruded in step 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com