Preparation method of polymer electrolyte taking cellulose as additive

A polymer and electrolyte technology, applied in the direction of electrolyte immobilization/gelation, circuits, electrical components, etc., can solve the problems of low conductivity of polyvinylidene fluoride, and achieve easy preparation, good electrochemical performance, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

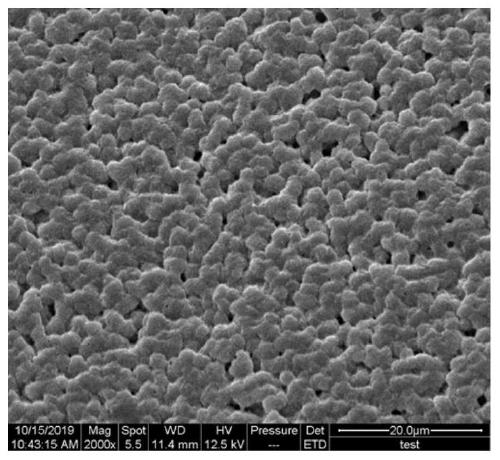

Image

Examples

specific Embodiment 1

[0034] Specific Example 1: A method for preparing a polymer electrolyte with cellulose as an additive in this embodiment:

[0035] 1. Pre-treatment of materials

[0036] Pre-treat all materials except lithium salts and liquid materials to ensure that the materials are sufficiently dry before use.

[0037] 2. Preparation of cellulose solution

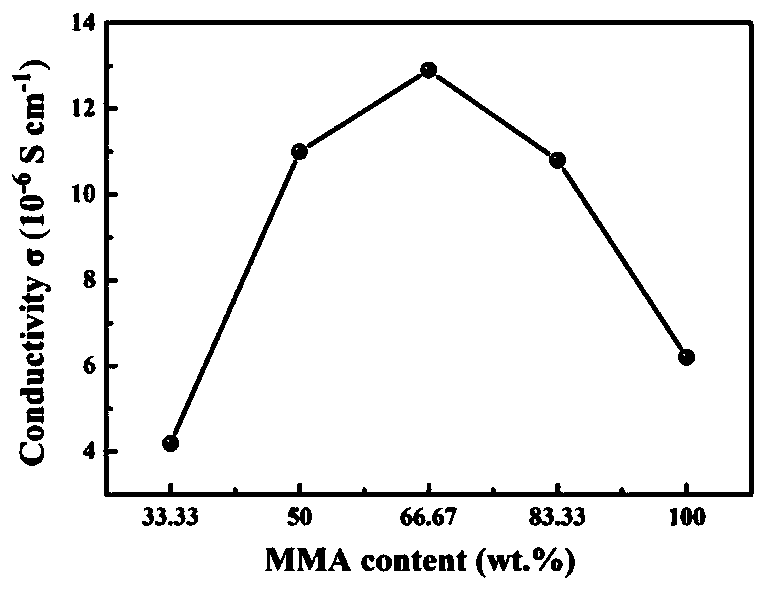

[0038] Dissolve a certain amount of polyvinylidene fluoride and hydroxypropyl methylcellulose in N,N dimethylformamide, heat in a water bath for a certain period of time to fully mix the two;

[0039] 3. Preparation of casting solution

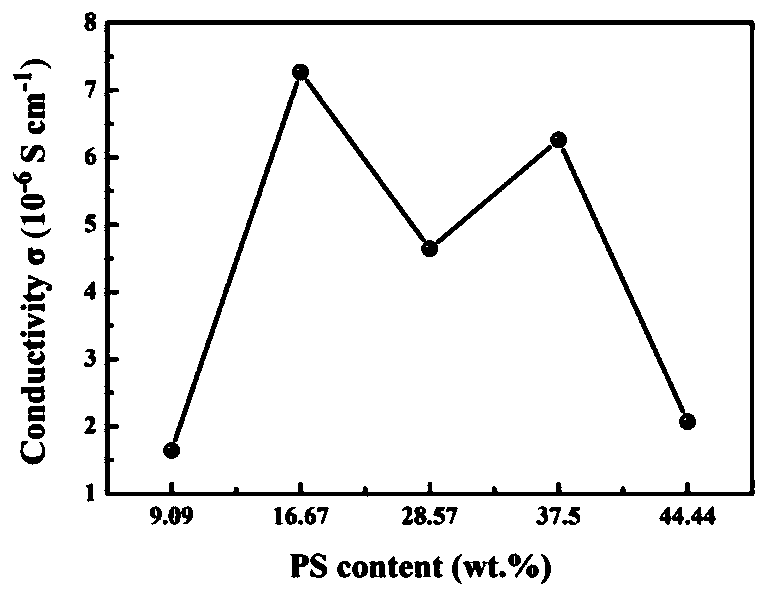

[0040] Take a certain quality of polystyrene and dissolve it in toluene. After the polystyrene is completely dissolved, add the cellulose solution in step 2 and add a corresponding quality of diluent. After stirring for 12 hours, add lithium bistrifluoromethanesulfonimide, Continue to stir for 6h to make the solution evenly dispersed;

[0041] 4. Preparation of Polymer Electrolyte

[0042] Cast the ...

specific Embodiment approach 2

[0053] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the pretreatment method described in step 1 is drying at 80° C. for 3 hours in a blast drying oven. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0054] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the temperature of the water bath heating described in step 2 is 60° C., and the heating time is 30 minutes. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com