A kind of production technology of light and thin fabric

A production process and fabric technology, applied in the field of textile fabrics, can solve problems such as the difficulty in obtaining light and thin cashmere fabrics, and achieve the effect of close worsted spinning effect, neat fiber arrangement, and light and thin fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

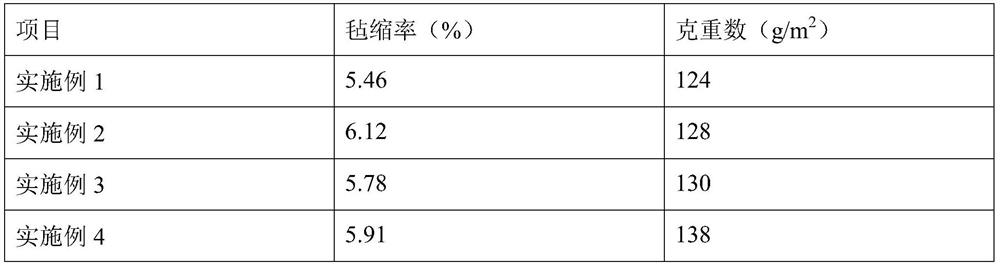

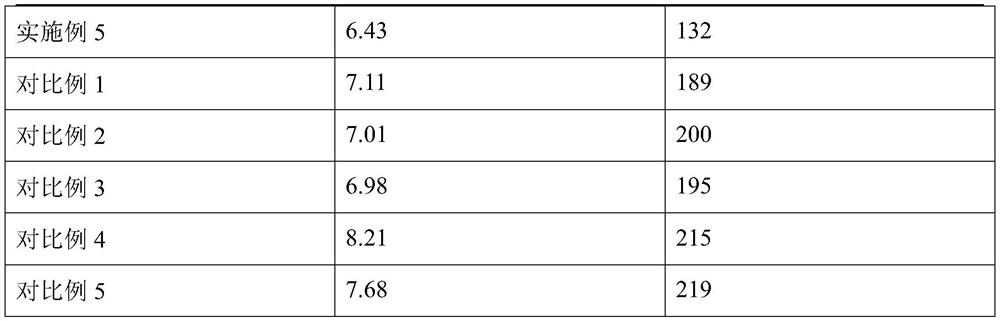

Examples

Embodiment 1

[0026] raw material selection

[0027] Pure cashmere with a fineness of 15.5±0.2μm, a length of 30-40mm, and a short cashmere rate of 5.2-7.5%.

[0028] Shampoo

[0029] Use tetrachlorethylene as a dry cleaning agent, seal the fabric and put it in a dry cleaner for 30 minutes, then take it out, then repeat the washing twice, immerse the fabric in acetic acid or formic acid for 1.5 hours, the quality of the fabric and acid The ratio is 1:28, then bake and carbonize at a temperature of 98°C, and then rinse with water at 49°C.

[0030] and wool

[0031] Adding wool oil additives to pure cashmere is SPINTEX-DSC and antistatic agent octadecyl dimethyl benzyl ammonium chloride, hair oil additives account for 2.5% by weight of pure cashmere, and antistatic agents account for 2.5% of pure cashmere Wool 0.8% by weight, adding hair oil additives and then stewing wool for 48 hours.

[0032] surface treatment

[0033] The pure cashmere is soaked in the treatment solution for 10-15 mi...

Embodiment 2

[0042] raw material selection

[0043] Pure cashmere with a fineness of 15.5±0.2μm, a length of 30-40mm, and a short cashmere rate of 5.2-7.5%.

[0044] Shampoo

[0045] Use tetrachlorethylene as a dry cleaning agent, seal the fabric and put it in a dry cleaner for 30 minutes, then take it out, then repeat the washing twice, immerse the fabric in acetic acid or formic acid for 1.5 hours, the quality of the fabric and acid The ratio is 1:28, then bake and carbonize at a temperature of 98°C, and then rinse with water at 49°C. and wool

[0046] Adding hair oil additives to pure cashmere is SPINTEX-DSC and antistatic agent octadecyl dimethyl benzyl ammonium chloride, hair oil additives account for 2% by weight of pure cashmere, and antistatic agents account for pure goat cashmere Wool 1% by weight, adding hair oil additives and then stewing wool for 32 hours.

[0047] surface treatment

[0048] The pure cashmere was soaked in the treatment solution for 10 minutes and then dri...

Embodiment 3

[0057] raw material selection

[0058] Pure cashmere with a fineness of 15.5±0.2μm, a length of 30-40mm, and a short cashmere rate of 5.2-7.5%.

[0059] Shampoo

[0060] Use tetrachlorethylene as a dry cleaning agent, seal the fabric and put it in a dry cleaner for 30 minutes, then take it out, then repeat the washing twice, immerse the fabric in acetic acid or formic acid for 1.5 hours, the quality of the fabric and acid The ratio is 1:28, then bake and carbonize at a temperature of 98°C, and then rinse with water at 49°C.

[0061] and wool

[0062] Adding hair oil additives to pure cashmere is SPINTEX-DSC and antistatic agent octadecyl dimethyl benzyl ammonium chloride, hair oil additives account for 3% by weight of pure cashmere, and antistatic agents account for pure goat cashmere Wool 0.5% by weight, add hair oil additives and stew wool for 36 hours.

[0063] surface treatment

[0064] The pure cashmere was soaked in the treatment solution for 10 minutes and then dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com