NiMA1Y/Al2O3 composite coating and preparation method thereof and application thereof

A composite coating, alloy target technology, applied in the coating, metal material coating process, vacuum evaporation plating and other directions, can solve the problems of poor mechanical properties, bonding force, peeling, etc., to improve performance and high controllability , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

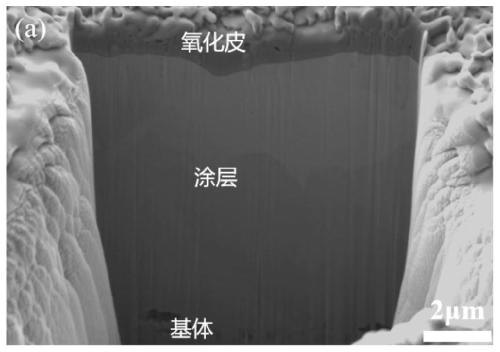

[0030] Another aspect of the embodiments of the present invention also provides a NiMAlY / Al 2 O 3 The preparation method of the composite coating includes:

[0031] Using physical vapor deposition technology, NiMAlY alloy target and Al target are used as target materials, inert gas is used as working gas, target current is applied to the NiMAlY alloy target and Al target, and bias is applied to the substrate, thereby sequentially depositing on the surface of the substrate. NiMAlY layer and Al layer, wherein M is selected from any one of Cr, Si, and Pt;

[0032] And, pre-oxidizing the Al layer to form Al 2 O 3 Layer to obtain NiMAlY / Al 2 O 3 Composite coating.

[0033] Further, the preparation method includes: using any one of multi-arc ion plating technology, magnetron sputtering technology, vapor deposition technology, and atomic layer deposition technology to sequentially deposit NiMAlY layer and Al layer on the surface of the substrate. .

[0034] In some more specific embodiments...

Embodiment 1

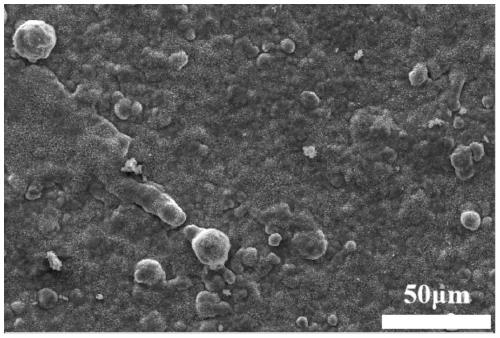

[0058] A NiSiAlY / Al 2 O 3 Composite coating, its thickness is 9μm, NiSiAlY layer thickness is 6μm, Al 2 O 3 The layer thickness is 3μm. The NiSiAlY / Al 2 O 3 The composite coating can be prepared according to the following steps:

[0059] (1) Cleaning, degreasing and surface activation of the cost surface. First, use solvents such as ethanol and acetone to ultrasonically clean and degrease the GH4169 superalloy workpiece. Put the cleaned sample into the coating equipment, apply a vacuum environment, and keep the temperature at 180°C. The surface of the workpiece needs to be activated by argon, the gas flow is 500sccm, and the negative bias voltage of ion etching is 900V, 1100V and 1200V. Each etching time is 2min.

[0060] (2) The pretreated workpiece is prepared with a multi-arc ion plating method to prepare a composite coating. The target material for depositing the NiSiAlY layer is a NiSiAlY alloy target, and the target composition includes 84wt% Ni, 2.5wt% Si, 12wt% Al, 1.5wt...

Embodiment 2

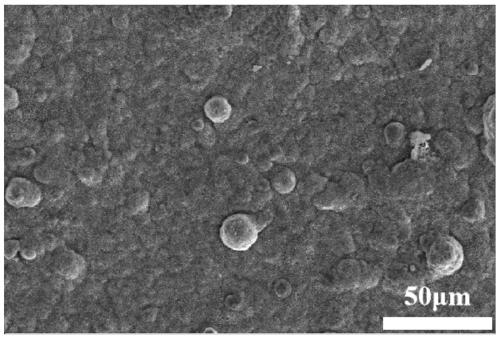

[0065] A NiSiAlY / Al 2 O 3 Composite coating, its thickness is 8μm, NiSiAlY layer thickness is 6μm, Al 2 O 3 The layer thickness is 2μm. The NiSiAlY / Al 2 O 3 The composite coating can be prepared according to the following steps:

[0066] (1) Cleaning, degreasing and surface activation of the cost surface. First, use solvents such as ethanol and acetone to ultrasonically clean and degrease the GH4169 superalloy workpiece. Put the cleaned sample into the coating equipment, apply a vacuum environment, and keep the temperature at 210°C, the surface of the workpiece needs to be activated by argon, the gas flow is 500sccm, and the negative bias voltage of ion etching is 900V, 1100V and 1200V. Each etching time is 2min.

[0067] (2) The pretreated workpiece is prepared with a multi-arc ion plating method to prepare a composite coating. The target material for depositing the NiSiAlY layer is a NiSiAlY alloy target, and the target material includes 84wt% Ni, 2.5wt% Si, 12wt% Al, and 1.5w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com