An aluminum alloy plate composite-solution quenching integrated hot forming method

A solution quenching, aluminum alloy plate technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of work hardening, forming limitation, etc., to eliminate work hardening, realize plastic deformation, small volume and footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An aluminum alloy plate body composite-solution quenching integrated hot forming method, the specific steps are as follows:

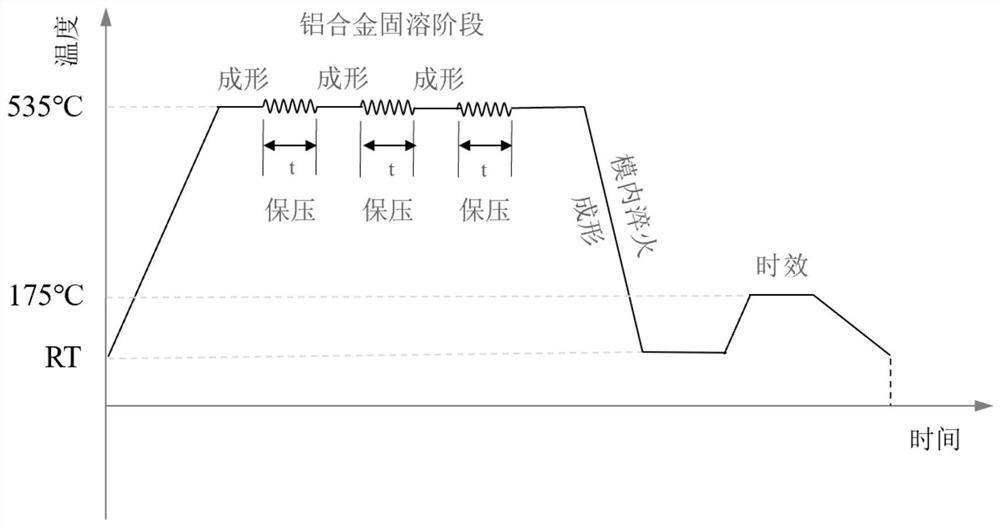

[0033] Such as image 3 As shown, it is the forming process route designed by the present invention for complex high-rib parts, and the process route is explained by taking aluminum alloy 2219 as an example;

[0034] The process route for complex parts with high ribs and thin webs uses the multi-pass plate forming in the solid solution stage + the final quenching forming process to realize the forming of such parts. For this process, the heating method is selected as induction heating;

[0035] First, heat the sheet and the mold to 535°C by induction heating, and the heating rate is 10°C / min. After the temperature is stable, perform the first pass of sheet forming, and the single pass reduction is controlled within 0.5mm;

[0036] After the end of one pass, the interval time is 2 minutes. During this period, the aluminum alloy undergoes static r...

Embodiment 2

[0040] An aluminum alloy plate body composite-solution quenching integrated hot forming method, the specific steps are as follows:

[0041] Such as image 3 As shown, it is the forming process route designed by the present invention for complex high-rib parts, and the process route is explained by taking aluminum alloy 2219 as an example;

[0042] The process route for complex parts with high ribs and thin webs uses the multi-pass plate forming in the solid solution stage + the final quenching forming process to realize the forming of such parts. For this process, the heating method is selected as induction heating;

[0043] First, heat the sheet and the mold to 500°C by induction heating, and the heating rate is 10°C / min. After the temperature is stable, perform the first pass of sheet forming, and the single-pass reduction is controlled within 0.5mm;

[0044] After the end of one pass, the interval time is 2 minutes. During this period, the aluminum alloy undergoes static r...

Embodiment 3

[0048] An aluminum alloy plate body composite-solution quenching integrated hot forming method, the specific steps are as follows:

[0049] Such as image 3 As shown, it is the forming process route designed by the present invention for complex high-rib parts, and the process route is explained by taking aluminum alloy 2219 as an example;

[0050] The process route for complex parts with high ribs and thin webs uses the multi-pass plate forming in the solid solution stage + the final quenching forming process to realize the forming of such parts. For this process, the heating method is selected as induction heating;

[0051] First, heat the sheet and the mold to 550°C by induction heating, and the heating rate is 10°C / min. After the temperature is stable, perform the first pass of sheet forming, and the single-pass reduction is controlled within 0.5mm;

[0052] After the end of one pass, the interval time is 2 minutes. During this period, the aluminum alloy undergoes static r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com