Spinning device and forming method for laser assisted shearing

A laser-assisted, spinning forming technology, applied in feeding devices, positioning devices, storage devices, etc., can solve the problems of no laser heat source irradiation, lack of precise position control parameters, etc., to avoid serious work hardening, and is conducive to engineering. Application, the effect of improving the forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

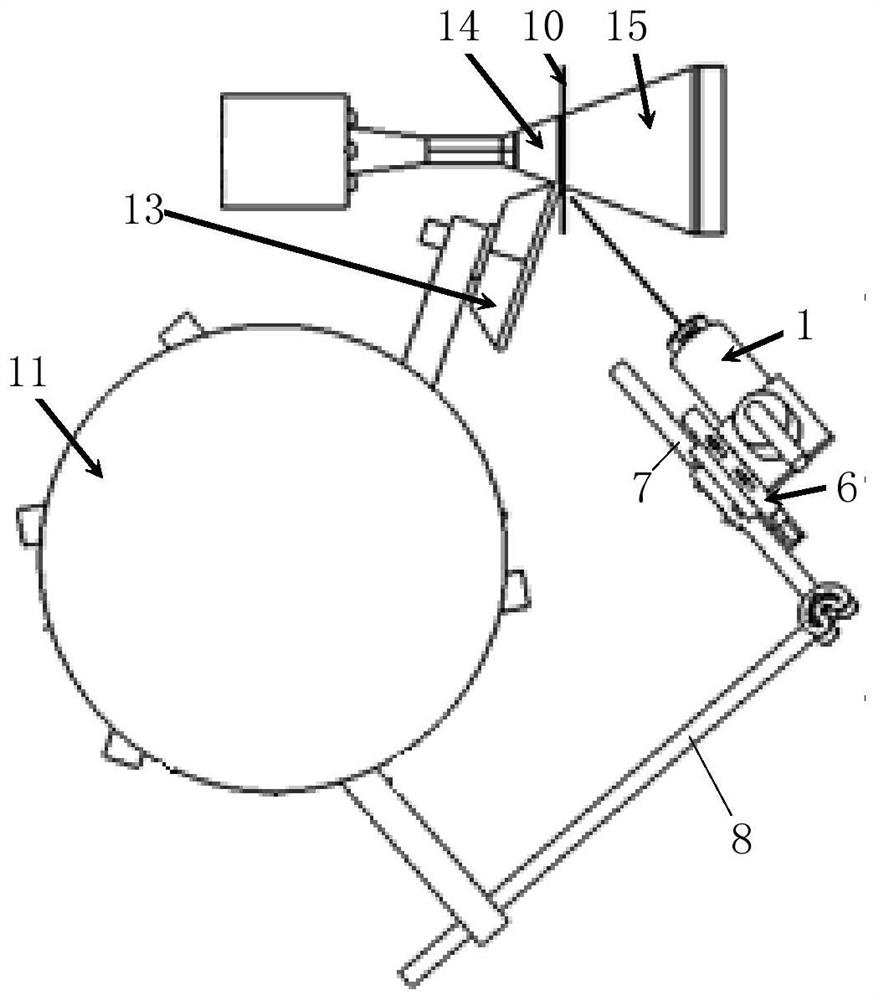

[0091] The invention provides a spinning device for laser-assisted shearing, including a spinning assembly and a laser adjustment assembly, the laser adjustment assembly includes a laser 1, and the laser 1 is installed on the spinning assembly through an adjustable connection assembly, wherein , the laser 1 is used to irradiate the workpiece and can correct the irradiation position of the laser 1 on the workpiece through an adjustable connection assembly, and the spinning assembly is used for spinning the workpiece 10 .

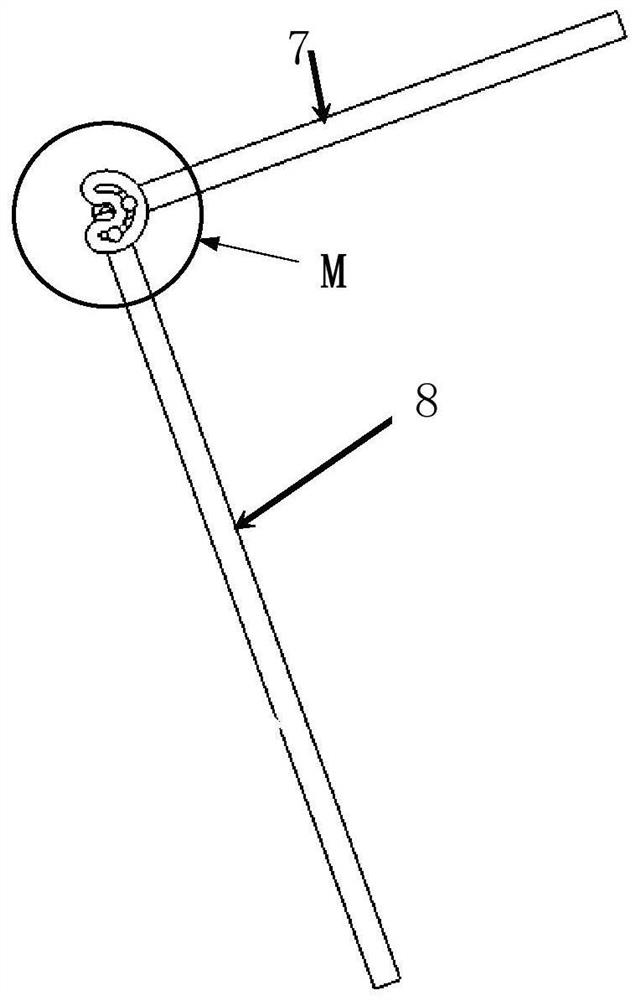

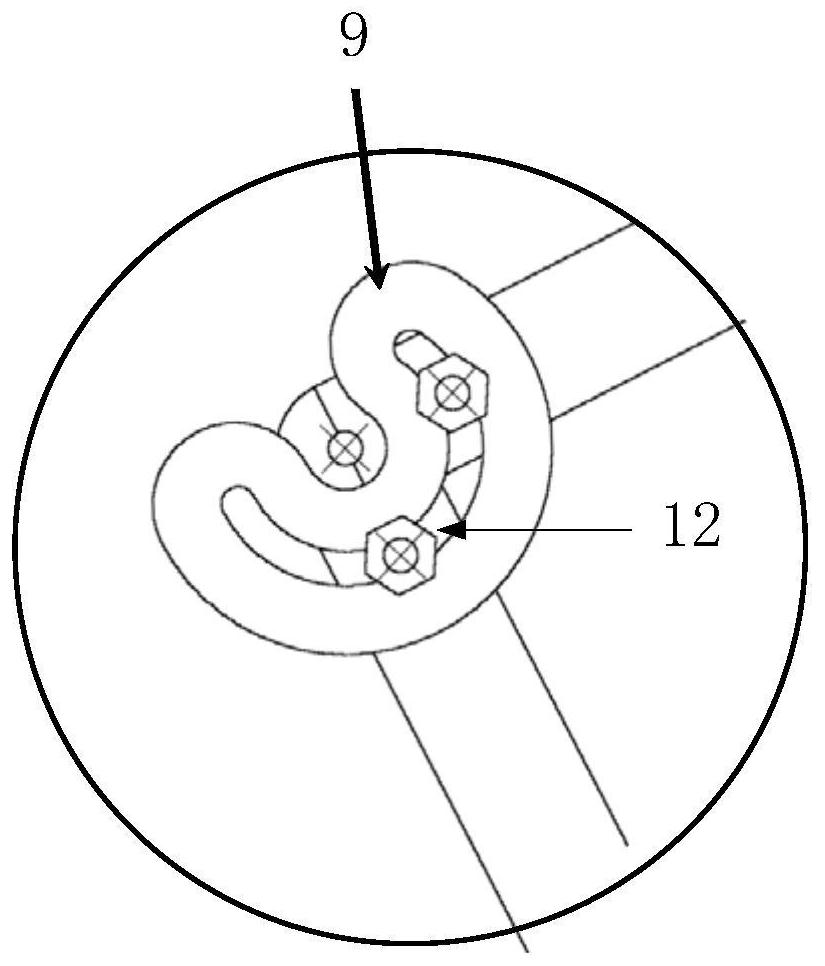

[0092] Specifically, the spinning assembly includes a support frame, the adjustable connection assembly includes a connecting rod structure and a moving assembly, one end of the connecting rod structure is installed on the supporting frame, and the moving assembly is connected to the other end of the connecting rod structure , the laser 1 is installed on the mobile assembly. The two connecting rods of the connecting rod structure, the first connecting rod 7 a...

Embodiment 2

[0110] In this embodiment, an aluminum alloy cylinder with a half taper angle of 20° and a radius of the small end of 20mm is selected as the finished product. The workpiece 10 is a 2024 aluminum alloy circular blank with a radius of 100mm and a thickness of 2mm. Laser-assisted shearing and spinning, the fillet radius r of the rotary wheel 13 is 5 mm.

[0111] Step S1: Spinning process parameter design, according to 2024 aluminum alloy, select the feed rate f as 1㎜ / r, and determine the radius R of the blank laser irradiation spot 18 according to the feed rate f and the radius of the round corner of the rotary wheel 13 5㎜ j It is 2.5㎜; according to the diameter of the small end of the 2024 aluminum alloy product, the constant linear velocity V of the mandrel for shearing and spinning is determined to be 100㎜ / s; according to the aluminum alloy material, the forming temperature is 300°C, and the YLR produced by the matching IPG company is used -1500 single-mode resonant laser tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com