Morphology-controllable hollow aluminum oxide microspheres as well as preparation method and application thereof

An alumina and hollow technology, applied in the preparation of aluminum hydroxide, chemical instruments and methods, applications, etc., can solve problems such as difficult to achieve repair, and achieve the effects of controllable morphology, large specific surface area, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing hollow alumina microspheres with controllable morphology, the steps are as follows:

[0020] Will Al 2 (SO 4 ) 3 , urea and ethylene glycol were added to distilled water to make Al 2 (SO 4 ) 3 The concentration is 0.15 mol·L -1 , the concentration of urea is 0.80 mol·L -1 , the concentration of ethylene glycol is 0.008 mol·L -1 , take 250 mL of the above solution, magnetically stir at room temperature for 20 min, then transfer to a polytetrafluoroethylene reactor, 180 o C was reacted for 24 h. After taking it out, it was naturally cooled to room temperature. The product was washed three times with absolute ethanol and water respectively, and the precipitate -30 o C freeze-dried for 24 h, and then in a muffle furnace at 500 o C was calcined for 2 h to obtain hollow Al 2 o 3 The microspheres have an average particle size of 4.2 μm and a wall thickness of 0.7 μm.

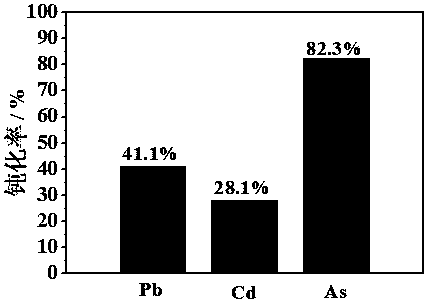

[0021] Weigh 5.00 g of heavy metal contaminated soil samples (Pb, Cd and A...

Embodiment 2

[0023] A method for preparing hollow alumina microspheres with controllable morphology, the steps are as follows:

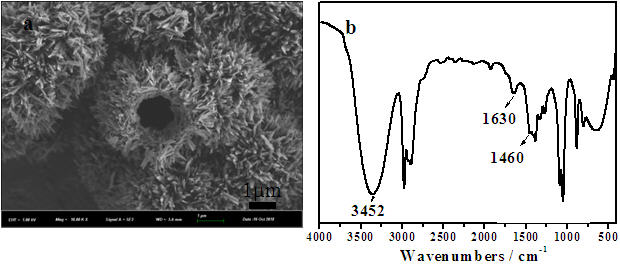

[0024] Al(NO 3 ) 3 , urea and polyethylene glycol PEG-400 were added to distilled water to make Al(NO 3 ) 3 The concentration is 0.2 mol·L -1 , urea concentration is 1.0mol L -1 , The concentration of polyethylene glycol PEG-400 is 0.008 mol L -1 , take 250 mL of the above solution, stir it magnetically for 20 min, then transfer it to a polytetrafluoroethylene reactor, 200 o C was reacted for 24 h. After taking it out, it was naturally cooled to room temperature. The product was washed three times with absolute ethanol and water respectively, and the precipitate -40 o C freeze-dried for 24 h, and then in a muffle furnace at 600 o C was calcined for 2 h to obtain hollow Al 2 o 3 Microspheres, the microspheres have an average particle size of 4.4 μm and a wall thickness of 0.8 μm. The specific surface area, pore volume and pore diameter of the prepared ho...

Embodiment 3

[0027] A method for preparing hollow alumina microspheres with controllable morphology, the steps are as follows:

[0028] AlCl 3 , urea, and polyethylene glycol PEG-6000 are added to distilled water to make AlCl 3 The concentration is 0.25 mol·L -1 , the concentration of urea is 1.10 mol L -1 , The concentration of polyethylene glycol PEG-6000 is 0.008 mol L -1 , take 250 mL of the above solution, stir it magnetically for 20 min, then transfer it to a polytetrafluoroethylene reactor, 190 o C for 24 h. After taking it out, it was naturally cooled to room temperature, and the product was washed three times with absolute ethanol and water respectively, and the precipitate -50 o C freeze-dried for 24 h, and then in a muffle furnace at 1100 o C was calcined for 2 h to obtain hollow Al 2 o 3 The microspheres have an average particle size of 4.3 μm and a wall thickness of 0.6 μm.

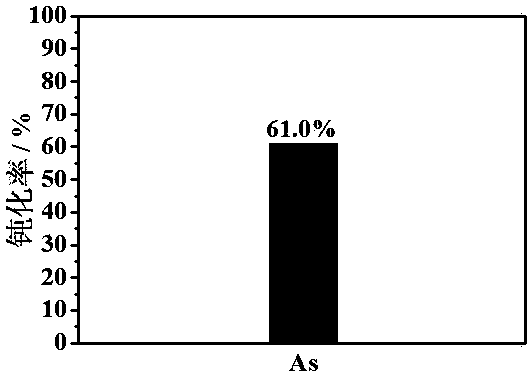

[0029]Weigh 5.00 g of heavy metal contaminated soil samples (Pb, Cd and As concentrations wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com