Low-energy-consumption desulfurization, desilicication and high-efficiency aluminum oxide dissolution treatment method for refractory bauxite

A processing method and difficult-to-treat technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of reducing industrial benefits, weak foundation, and lowering product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

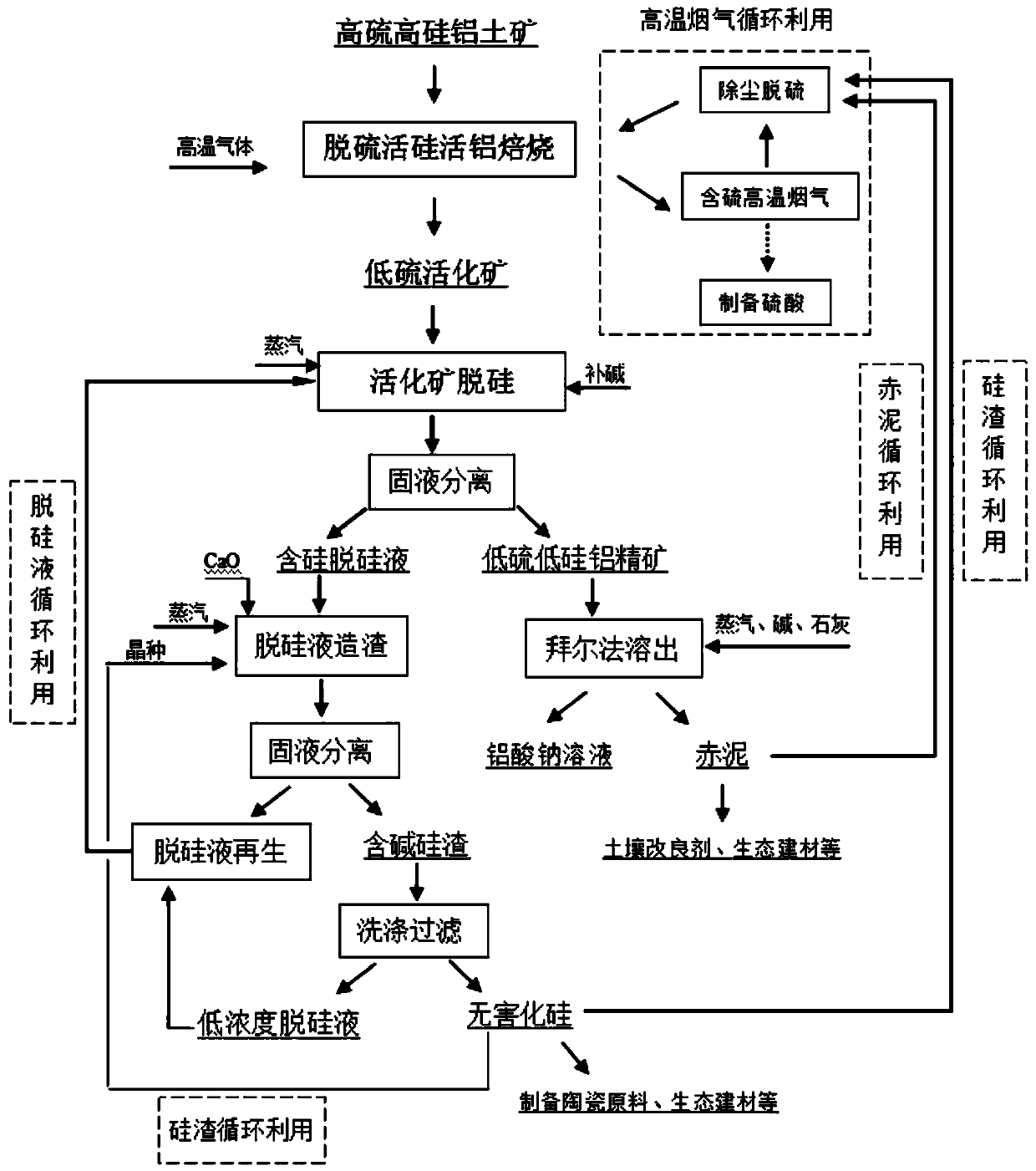

[0056] The present invention will be further described below in conjunction with the accompanying drawings.

[0057] like figure 1 As shown, a treatment method for refractory bauxite with low energy consumption, desulfurization, desiliconization, and high-efficiency alumina dissolution, which is suitable for diaspore-kaolinite type high-sulfur and high-silicon bauxite, 2 o 3 % content 50-70%, SiO 2 content>10%, aluminum-silicon ratio 3-5, sulfur content>1%, the specific steps are as follows:

[0058] a. Crushing and grinding: crush the bauxite raw material, and then grind it to form ore powder; the powder passes more than 60% of the 200-mesh standard sieve.

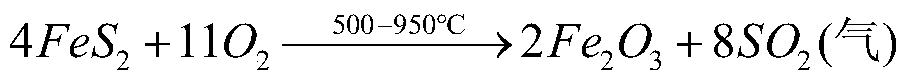

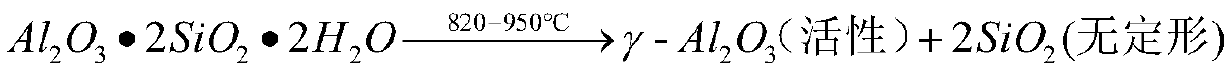

[0059]b. Desulfurization live silicon and live aluminum treatment: use fluidized roaster to carry out desulfurization live silicon live aluminum treatment on ore powder; pass high-temperature gas into the furnace body, control the temperature of the material contact reaction zone in the furnace to 820-950 ℃, and keep t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com