A preparation method of nickel-cobalt-manganese hydroxide nanoneedle/nitrogen-doped carbon/nickel foam electrode material

A technology of hydroxide and nitrogen-doped carbon, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors. It can solve the problems of material agglomeration, unstable structure, high specific energy and high cost performance, and achieve safe operation. Reliable, does not involve hazardous chemicals, the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

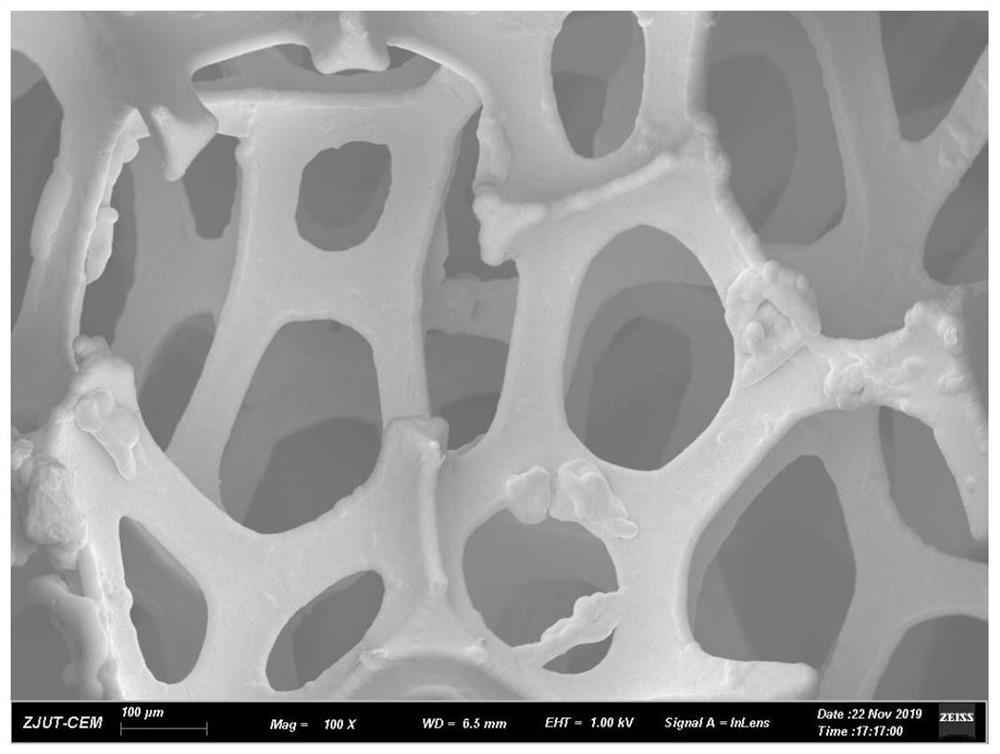

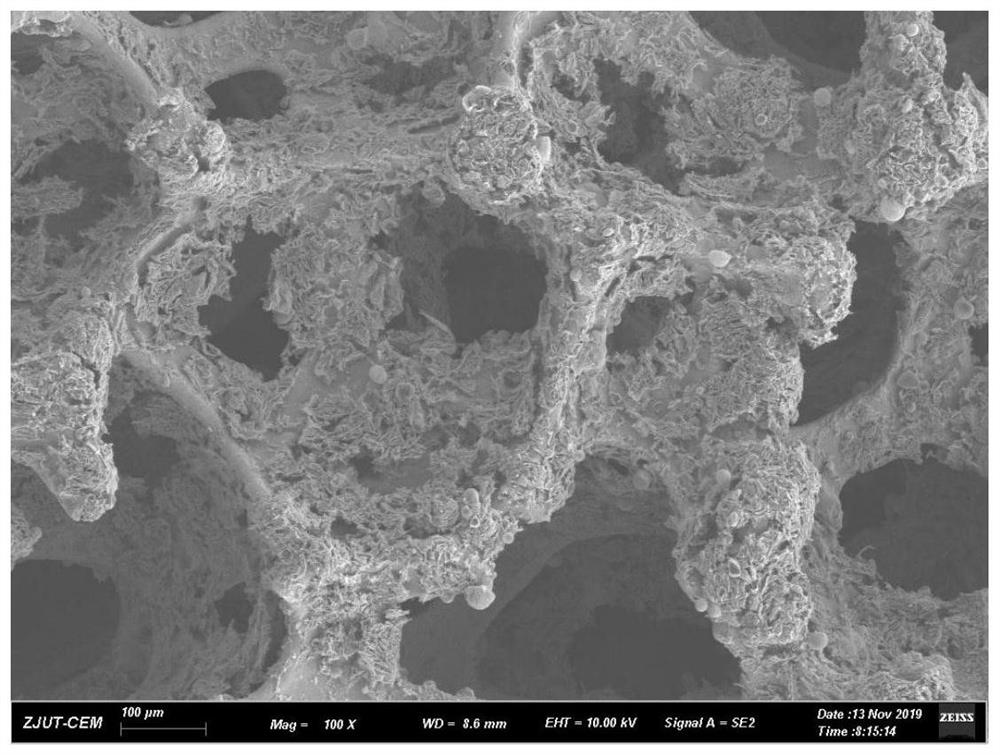

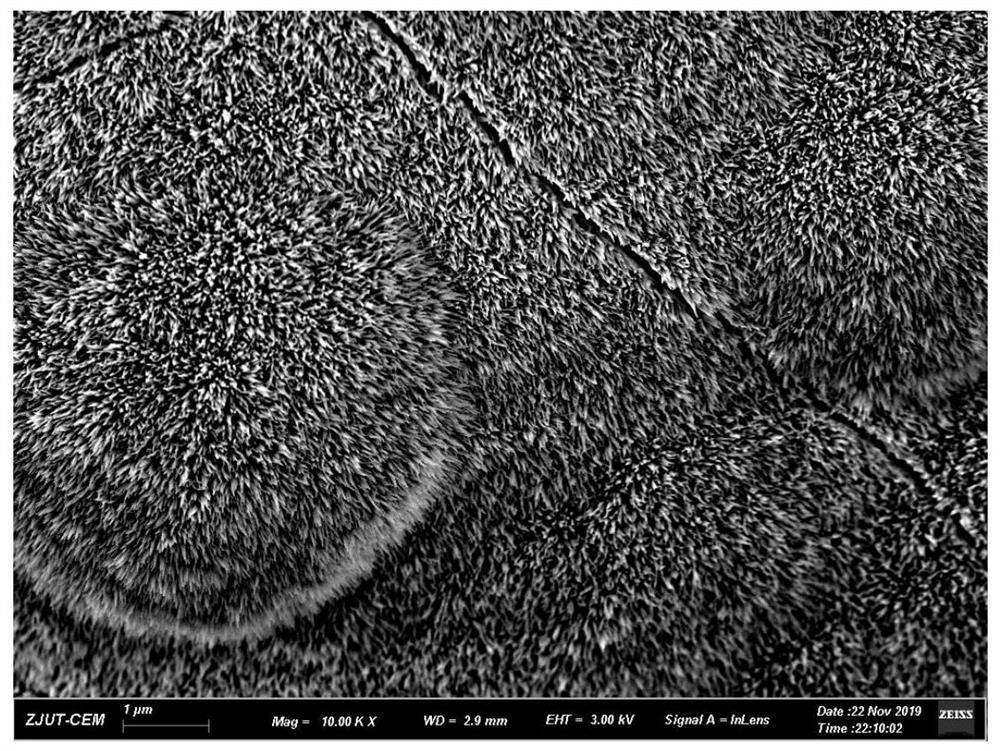

Method used

Image

Examples

Embodiment 1

[0044] (1) The nickel foam with a size of 2cm×4cm was ultrasonically cleaned with acetone, 3M HCl, deionized water, and absolute ethanol for 10 min, respectively, and dried at 45°C.

[0045] (2) Weigh nickel acetate (concentration 45mM), citric acid and urea are dissolved in 250ml ethanol and stir to make it dissolve completely, wherein the mass ratio of nickel acetate, citric acid and urea is 1:2:5;

[0046] (3) Place the nickel foam treated in step (1) in the mixed solution of 250mL step (2), and heat to 80°C until the crystals in the solution are completely precipitated;

[0047] (4) Calcining the nickel foam treated in step (3) in argon at 350° C. for 2 h, and then at 650° C. for 2 h, with a heating rate of 5° C. / min.

[0048] (5) Weigh 2mmol of nickel nitrate, 2mmol of cobalt nitrate, 2mmol of manganese nitrate and 2.5mmol of urea and dissolve them in 30mL of deionized water, stir evenly to dissolve them completely;

[0049](6) Place the nickel foam obtained in step (4) ...

Embodiment 2

[0053] (1) The nickel foam with a size of 2cm×4cm was ultrasonically cleaned with acetone, 2M HCl, deionized water, and absolute ethanol for 15 minutes, and dried at 60°C.

[0054] (2) Weigh nickel chloride (concentration 30mM), citric acid and urea and dissolve them in 100ml of ethylene glycol and stir to dissolve them completely, wherein the mass ratio of nickel chloride, citric acid and urea is 1:2:7;

[0055] (3) the nickel foam after step (1) treatment is placed in the mixed solution of 100ml step (2) and is heated to 60 ℃ until the crystal in the solution is completely separated out;

[0056] (4) Calcining the nickel foam treated in step (3) at 350° C. for 8 hours in argon with a heating rate of 8° C. / min.

[0057] (5) Take by weighing 1mmol nickel chloride, 1mmol cobalt chloride, 1mmol manganese chloride and 1.5mmol urea and dissolve them in 30ml deionized water, stir to make them completely dissolve;

[0058] (6) Place the nickel foam obtained in step (4) in the mixed...

Embodiment 3

[0062] (1) Nickel foam with a size of 2cm×4cm was ultrasonically cleaned with acetone, 1M HCl, deionized water, and absolute ethanol for 20 minutes, and dried at 70°C.

[0063] (2) Take nickel nitrate (concentration 40mM), citric acid and urea and dissolve it in 200ml glycerol and stir to make it dissolve completely, wherein the mass ratio of nickel nitrate, citric acid and urea is 1:2:10;

[0064] (3) 200ml of nickel foam treated in step (1) is placed in the mixed solution of step (2) and heated to 40°C until the crystals in the solution are completely separated out;

[0065] (4) Calcining the nickel foam treated in step (3) at 650° C. for 2 hours in argon with a heating rate of 20° C. / min.

[0066] (5) Take by weighing 0.1mmol nickel nitrate, 0.1mmol cobalt nitrate, 0.1mmol manganese nitrate and 0.5mmol urea and dissolve them in 30ml deionized water, stir evenly to make them dissolve completely;

[0067] (6) Place the nickel foam obtained in step (4) in the mixed solution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com