Fluoride red fluorescent powder and luminescent device based on fluorescent powder

A technology for red phosphors and light-emitting devices, applied in the directions of light-emitting materials, semiconductor devices, chemical instruments and methods, etc., can solve the problems of easy hydrolysis, low fluorescence quantum efficiency, and poor reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

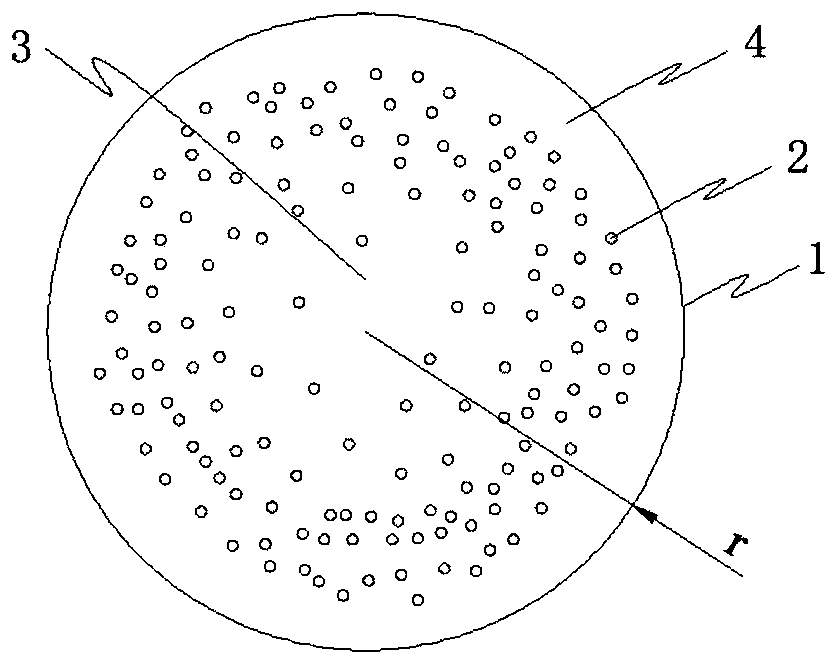

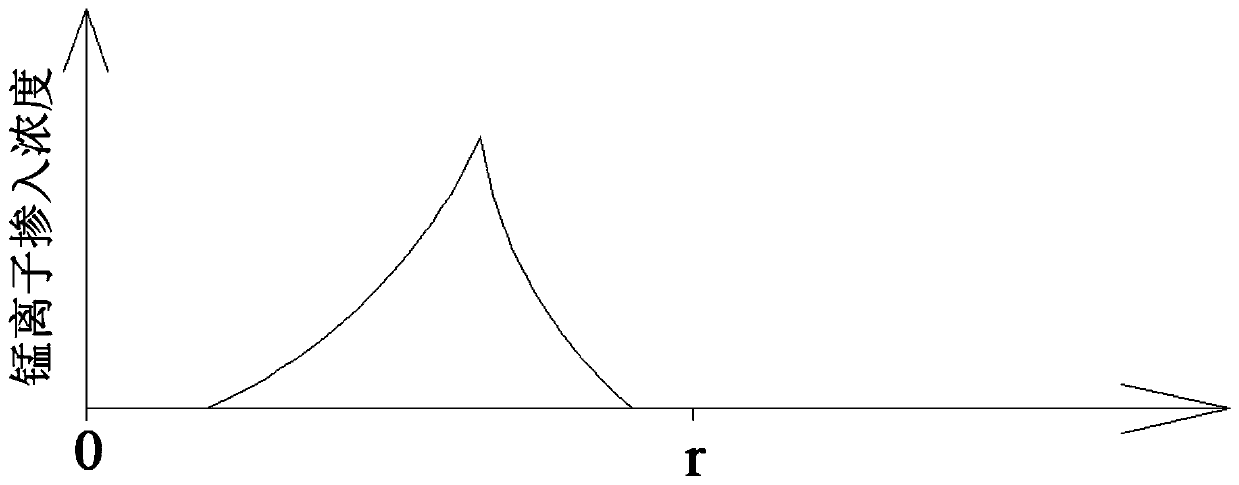

[0045] Please refer to Figure 1 to Figure 2 , A fluoride red phosphor, which is tetravalent manganese ion Mn 4+ Doped with K 2 TiF 6 As the luminescent ion in the matrix particles 1, K is potassium, F is fluorine, and the doped Mn 4+ Partially replace K 2 TiF 6 Tetravalent Ti in matrix particles 4+ Ion, the Mn 4+ Replace Ti 4+ The mole percentage of ions is Mn 4+ The incorporation concentration.

[0046] The K 2 TiF 6 There is a zero-incorporation zone 3 in the center of the matrix particle. The K 2 TiF 6 The matrix particles have a second zero-incorporation area close to the outer surface 4, Mn 4+ The doping concentration of ions 2 starts from the edge of the zero doping region 3 and continuously increases from zero to the maximum value, and then continuously decreases from the maximum value until it drops to zero at the edge of the second zero doping region 4.

[0047] The K 2 TiF 6 The matrix particle 1 is a matrix particle with a continuous lattice structure. 2 TiF 6 There is ...

Embodiment 2

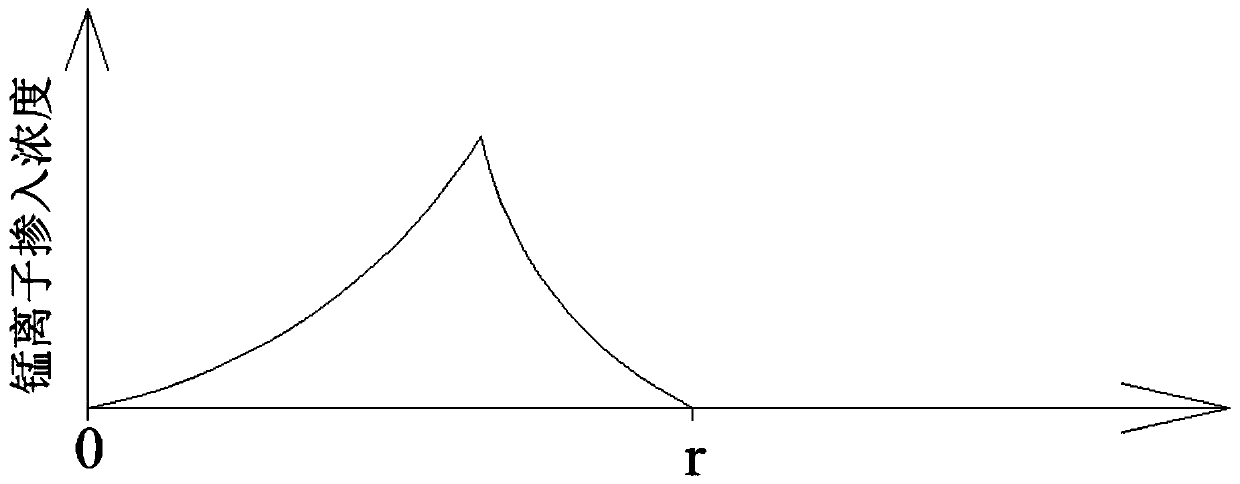

[0061] Please refer to image 3 Steps S106 and S107 in the first embodiment are omitted. In step S101, K 2 MnF 6 The concentration in the solution is 0.05 g / ml, and in step S102, the stirring time is 10 minutes. The K 2 TiF 6 There is a zero-incorporation zone 3 in the center of the matrix particle. Mn 4+ The doping concentration of ions is from the K 2 TiF 6 The center of the matrix particle first continuously increases from zero to the maximum value, and then continuously decreases from the maximum value until the K 2 TiF 6 The outer surface of the matrix particles is reduced to zero.

[0062] The K 2 TiF 6 The average particle size of the matrix particles is 9 microns. The K 2 TiF 6 The matrix particle 1 is a matrix particle with a continuous lattice structure. 2 TiF 6 There is no layered crystalline interface in any region from the center of the matrix particle 1 to the radial direction of its surface. 2 TiF 6 :Mn 4+ The peak wavelength of the red phosphor is around 631nm.

...

Embodiment 3

[0065] A fluoride red phosphor, which is tetravalent manganese ion Mn 4+ Incorporate K 2 SiF 6 The matrix particles act as luminescent ions.

[0066] K 2 SiF 6 The diameter of the matrix particles is 25 microns and the radius is 12.5 microns. 2 SiF 6 The total length in the radial direction from the center of the matrix particle to its surface is 12.5 microns, the position of the maximum incorporation concentration is 8.75 microns in the radial direction from the center of the matrix particle to its surface, and the outer edge of the zero incorporation region The position is 2.5 micrometers in the radial direction from the center of the matrix particle to its surface, and the thickness of the second zero-incorporation region is 1.25 micrometers.

[0067] Preparation of the K 2 SiF 6 :Mn 4+ In the method of fluoride red phosphor,

[0068] In the S101 step, K 2 MnF 6 The concentration in the solution is 0.06g / ml;

[0069] In the step S102, at 25°C, the K with an average particle diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com