Method for producing hydrochloric acid-liquid caustic soda-composite material by utilizing industrial waste impure salt

A composite material and industrial technology, applied in the field of solid waste treatment, can solve the problems of unacceptable, high purification and treatment costs, affecting product quality and downstream market acceptance and resource utilization, so as to reduce transportation costs, reduce concentration costs, and avoid two The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

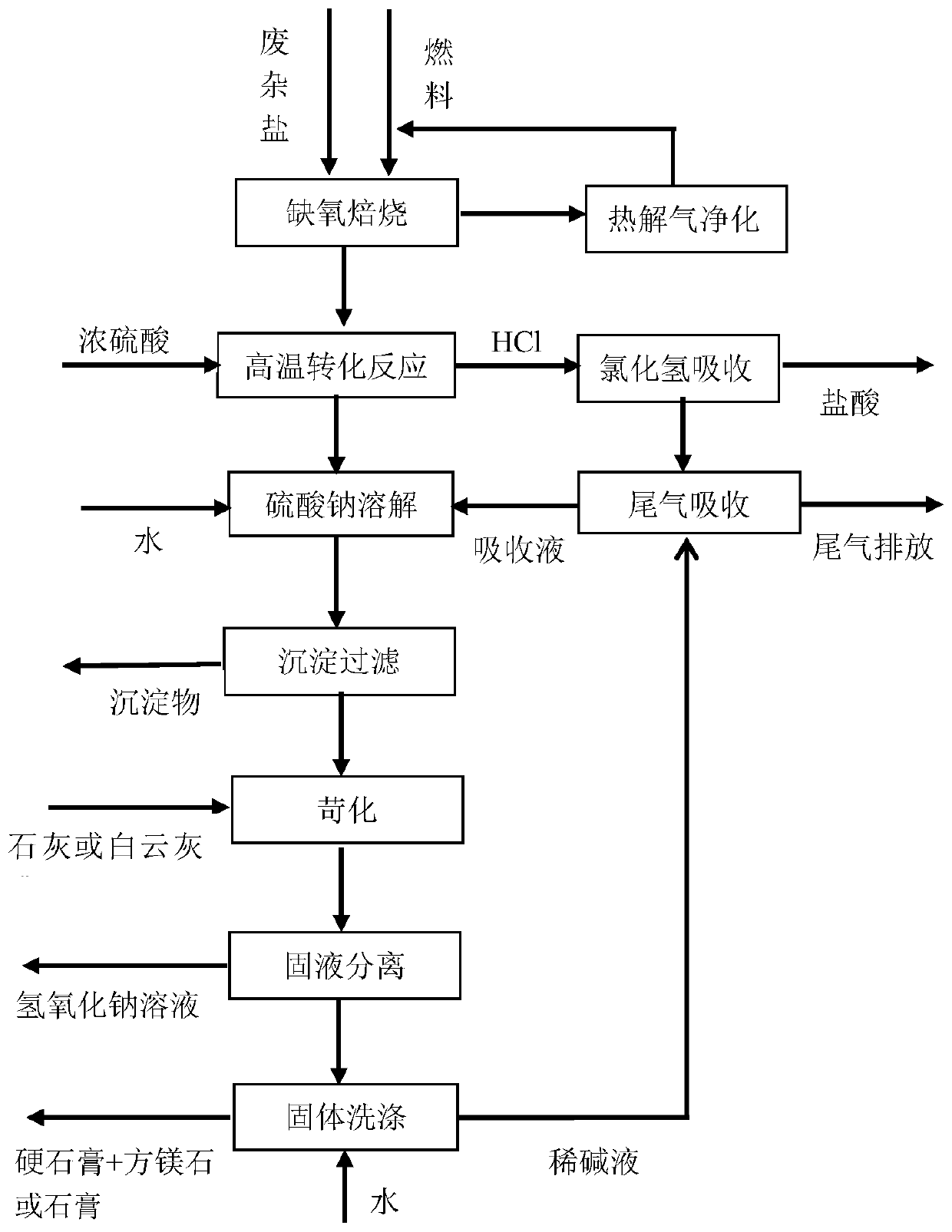

Image

Examples

Embodiment 1

[0029] In this example, 100 kg of waste salt rich in organic matter from a certain enterprise was taken. XRD analysis results showed that the main phase composition was common salt: NaCl content 83.6%, organic matter content 14.7%, and other impurities 1.7%. The waste salt is processed through the following steps:

[0030] Step 1. Using natural gas as fuel, the waste salt is roasted in an indirect heating roaster under an oxygen-deficient atmosphere at 500°C to pyrolyze the organic and decomposable inorganic impurities; The salt is heat-exchanged and condensed, washed and absorbed by sodium hydroxide solution with a mass concentration of 5%, and finally filtered and purified before being used as fuel for indirect heating roasters.

[0031] Step 2. React the roasted product in the high-temperature converter at 320-350° C. for 10 minutes with concentrated sulfuric acid having a mass concentration of 98% in a mass ratio of 1.2:1 to obtain HCl and SO 2 The gaseous product, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com