Conical roller

A conical roller, roller technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of insufficient strength, easy deformation, and inability to handle items to turn, so as to improve the load capacity and strengthen the connection. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following specific embodiments are only an explanation of the present invention, and are not a limitation of the present invention. After reading this specification, those skilled in the art can make modifications to this embodiment without creative contribution as needed, but as long as the rights of the present invention All requirements are protected by patent law.

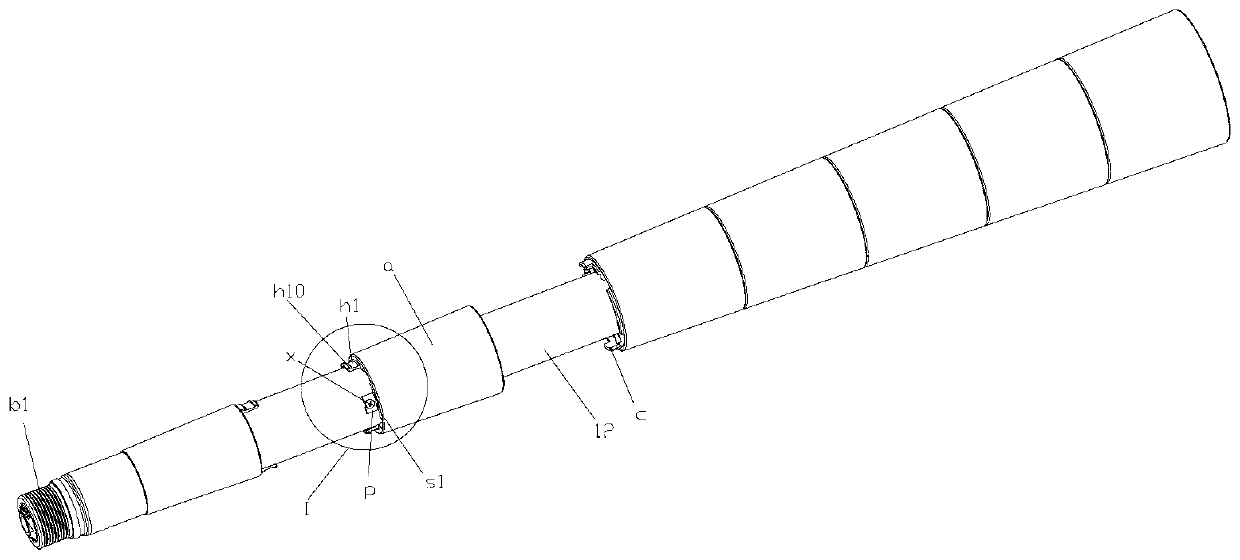

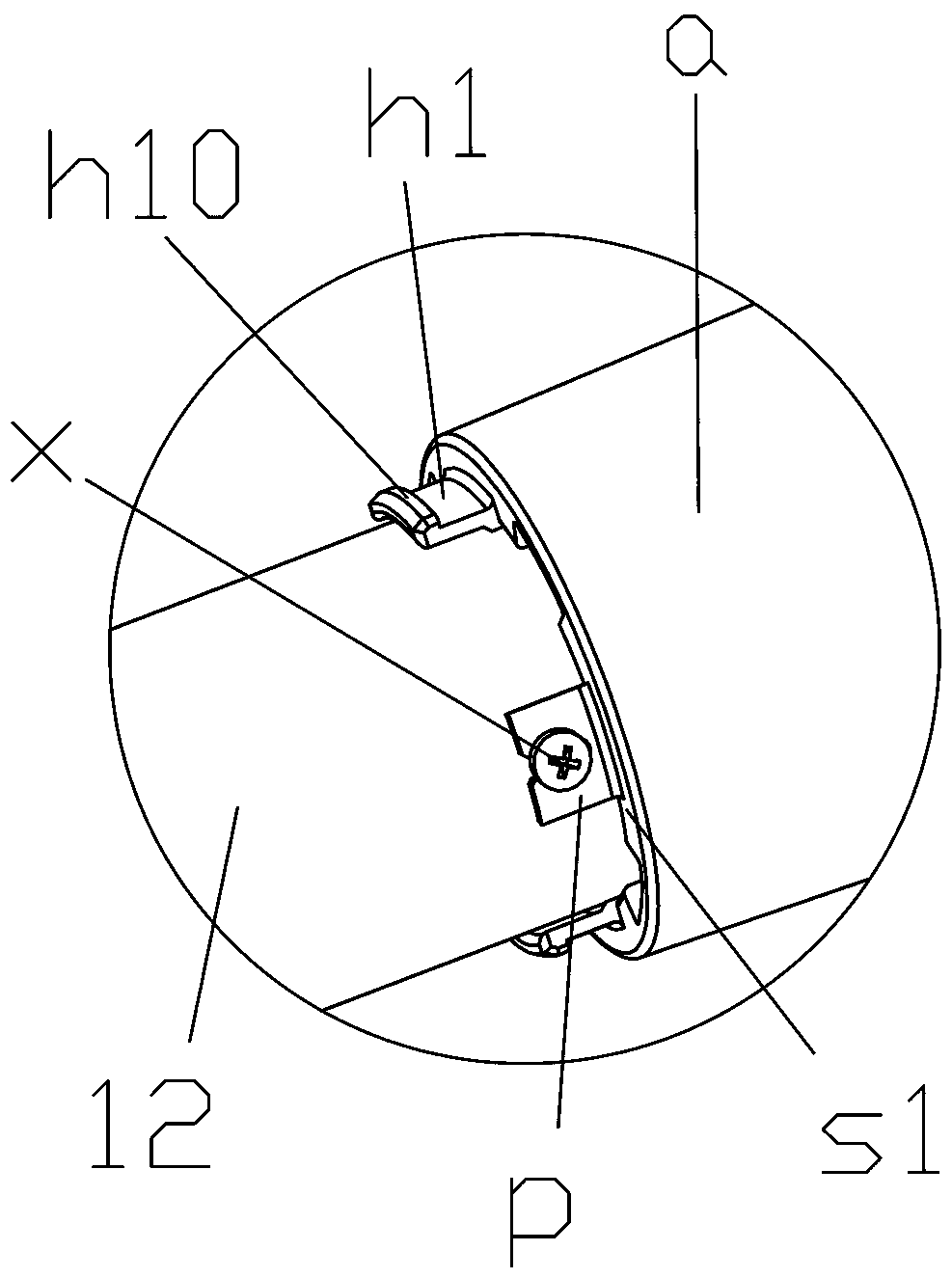

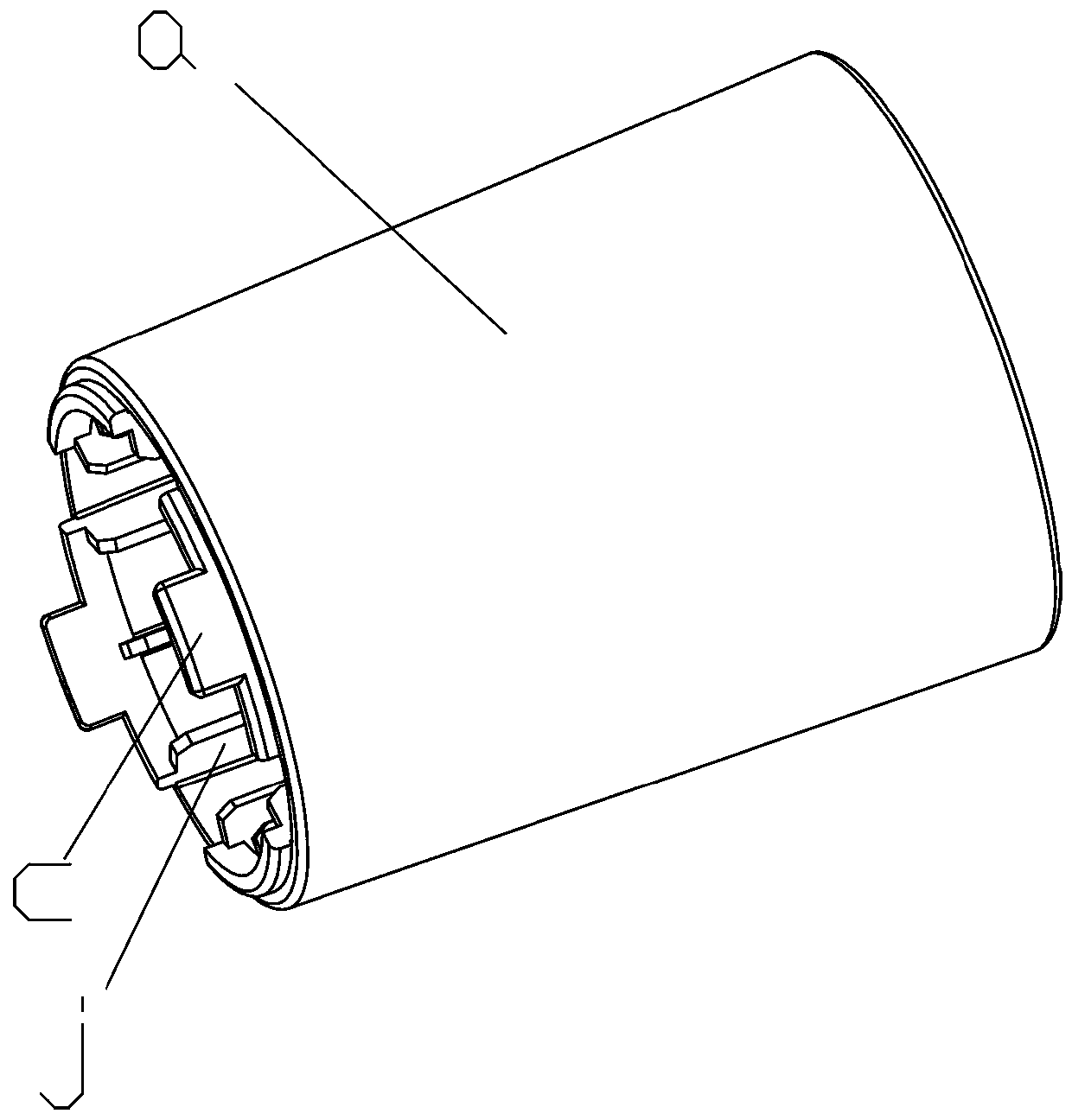

[0037] Examples such as Figure 1-13 As shown, a tapered roller includes an inner roller 1, and the inner roller 1 can adopt an existing roller structure, generally including a left bearing assembly b1 and a right bearing assembly b2, and can adopt conventional roller bearings with bearings The end bearing support assembly is mounted on the bearing between the left bearing assembly b1 and the right bearing assembly b2, and a roller shaft 11 and a steel tube with two ends sleeved on the left and right bearing assemblies and rolling around the roller shaft 11 Body 12, the outer periphery of the inner rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com