Method for making light-transmitting concrete relief and round sculpture

A technology of light-transmitting concrete and its production method, which is applied in the fields of manufacturing tools, ceramic molding machines, decorative arts, etc., can solve the problems affecting the aesthetics at night, etc., and achieve the effect of bright and transparent space, strong decoration, and good light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

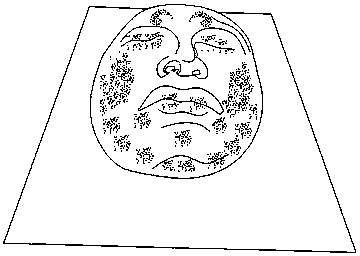

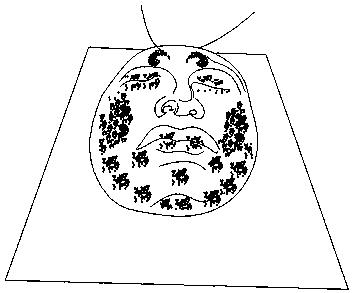

Image

Examples

Embodiment 1

[0024] A method for making light-transmitting concrete reliefs and round sculptures, comprising the following steps:

[0025] Step 1: Design the model of the object to be produced in 3Dmax. After the model design is completed, use a 3D printer to print out the female mold of the relief or round sculpture according to the design model. The inside of the female mold is empty, and the female mold is Concave mold, the female mold itself is covered with small holes, the diameter of the small holes is 2mm, and the distance between the small holes is 0.5cm;

[0026] The second step: Pass the optical fiber with a diameter of 1.5mm through the small hole, leave 4cm of optical fiber on both sides of the female mold, and fix it with colloid; each small hole passes through the optical fiber;

[0027] Step 3: Apply concrete release oil to the female mold;

[0028] Step 4: Pour the adjusted concrete mortar into the female mold of relief or round sculpture;

[0029] Step 5: Put the concret...

Embodiment 2

[0034] A method for making light-transmitting concrete reliefs and round sculptures, comprising the following steps:

[0035] Step 1: Design the model of the object to be produced in 3Dmax. After the model design is completed, use a 3D printer to print out the female mold of the relief or round sculpture according to the design model. The inside of the female mold is empty, and the female mold is Concave mold, the female mold itself is covered with small holes, the diameter of the small holes is 2.5mm, and the distance between the small holes is 0.8cm;

[0036] Step 2: Pass the optical fiber with a diameter of 2mm through the small hole, leave 6cm of optical fiber on both sides of the female mold, and fix it with colloid; each small hole passes through the optical fiber;

[0037] The third step: apply concrete release agent in the female mold;

[0038] Step 4: Pour the adjusted concrete mortar into the female mold of relief or round sculpture;

[0039] Step 5: Put the concre...

Embodiment 3

[0044] A method for making light-transmitting concrete reliefs and round sculptures, comprising the following steps:

[0045] Step 1: Design the model of the object to be produced in 3Dmax. After the model design is completed, use a 3D printer to print out the female mold of the relief or round sculpture according to the design model. The inside of the female mold is empty, and the female mold is Concave mold, the female mold itself is covered with small holes, the diameter of the small holes is 3.5mm, and the distance between the small holes is 1cm;

[0046] Step 2: Pass the optical fiber with a diameter of 3mm through the small hole, leave 5cm of optical fiber on both sides of the female mold, and fix it with colloid; each small hole passes through the optical fiber;

[0047] Step 3: Apply concrete release oil to the female mold;

[0048] Step 4: Pour the adjusted concrete mortar into the female mold of relief or round sculpture;

[0049] Step 5: Put the concrete mortar in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com