Carbon-coated transition metal nano composite material as well as preparation method and application thereof

A technology of nanocomposite materials and transition metals, which is applied in the field of carbon-coated transition metal nanocomposites and its preparation, can solve the problems of small metal nanoparticles, many fine powders, complex preparation process, etc., and achieve good low-temperature activity, The effect of improving mass transfer efficiency and improving transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] (1) Weigh 10 g of nickel acetate and 20 g of citric acid into 20 mL of deionized water, and stir at 50° C. to obtain a homogeneous solution.

[0114] (2) Add 2 g of silicon dioxide (Grace Company, model 2485) to the homogeneous solution obtained in step (1), continue stirring for 2 h, and heat and evaporate to dryness to obtain a solid microsphere precursor.

[0115] (3) Place the precursor obtained in step (2) in the porcelain boat, then place the porcelain boat in the constant temperature zone of the tube furnace, feed nitrogen gas at a flow rate of 100mL / min, and raise the temperature to 5°C / min. 600°C, keep the temperature constant for 2 hours, stop heating, and cool to room temperature under a nitrogen atmosphere to obtain a carbon-coated nickel nanocomposite material containing a carrier.

[0116] The percentages of elements contained in the surface of the nanocomposite obtained by XPS analysis are: carbon 81.99 at%, oxygen 13.41 at%, nickel 1.36 at%, silicon 3.24...

Embodiment 2

[0120] (1) Weigh 10 g of nickel acetate and 20 g of citric acid into 60 mL of deionized water, and stir at 70° C. to obtain a homogeneous solution.

[0121] (2) Add 4 g of pseudo-boehmite to the homogeneous solution obtained in step (1), continue stirring for 2 h, and heat and evaporate to dryness to obtain the solid microsphere precursor.

[0122] (3) Place the precursor obtained in step (2) in the porcelain boat, then place the porcelain boat in the constant temperature zone of the tube furnace, feed nitrogen gas at a flow rate of 100mL / min, and raise the temperature to 5°C / min. 650°C, keep the temperature constant for 1 hour, stop heating, and cool to room temperature under nitrogen atmosphere to obtain a carbon-coated transition metal nanocomposite material containing a carrier.

[0123] The percentages of elements contained on the surface of the material obtained by XPS analysis are: carbon 80.48 at%, oxygen 15.17 at%, nickel 0.73 at%, aluminum 3.62 at%.

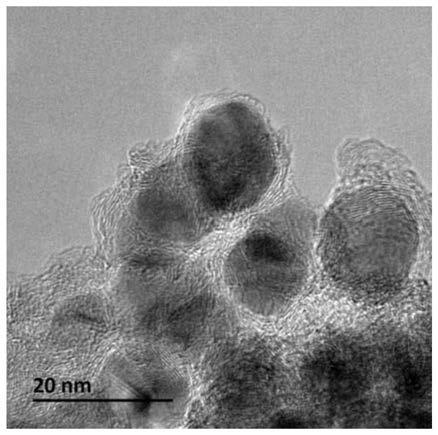

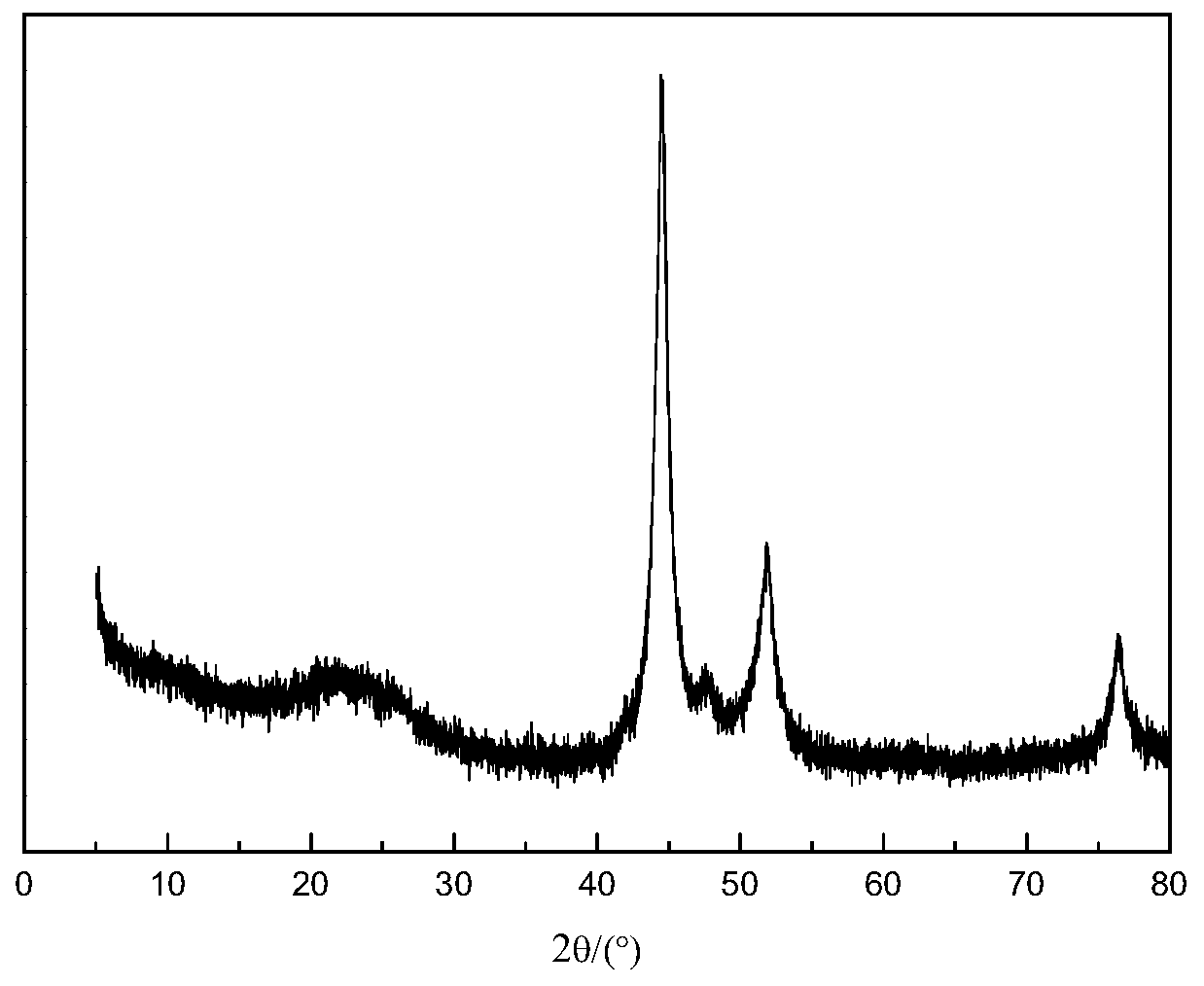

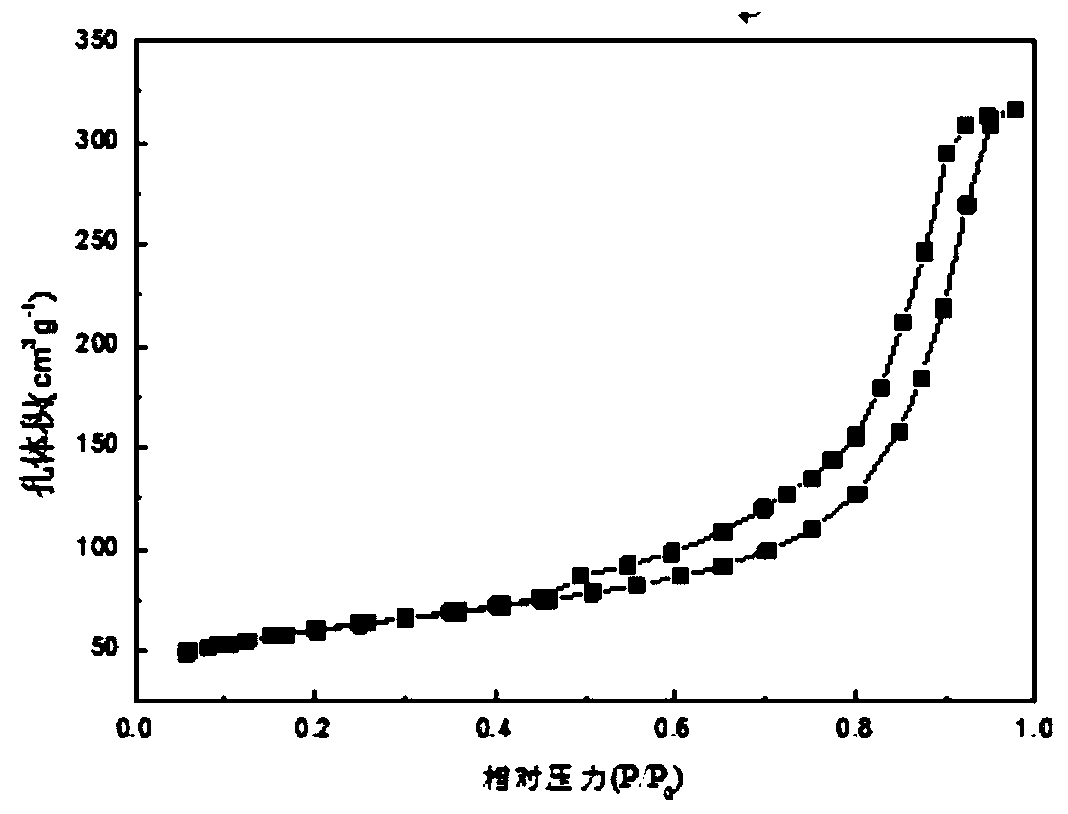

[0124] The TEM...

Embodiment 3

[0127] (1) Weigh 10 g of cobalt acetate and 10 g of ethylenediaminetetraacetic acid, add 150 mL of deionized water, and stir at 30° C. to obtain a homogeneous solution.

[0128] (2) Add 1 g of silicon dioxide (Grace Company, model 955) to the homogeneous solution obtained in step (1), continue stirring for 2 h, and evaporate to dryness by heating to obtain a solid microsphere precursor.

[0129] (3) Place the precursor obtained in step (2) in the porcelain boat, then place the porcelain boat in the constant temperature zone of the tube furnace, feed nitrogen gas at a flow rate of 100mL / min, and raise the temperature to 5°C / min. 750°C, keep the temperature constant for 1 hour, stop heating, and cool to room temperature under a nitrogen atmosphere to obtain a carbon-coated cobalt nanocomposite material containing a carrier.

[0130] The percentages of elements contained on the surface of the composite material obtained by XPS analysis are: carbon 85.84at%, oxygen 6.94at%, cobalt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com