Preparation method of high-power interception reinforced nano-structure composite membrane

A nano-structure composite and high-power technology, applied in the field of membrane separation, can solve the problems that anti-pollution and hydrophilicity have not been effectively improved, increasing the difficulty of continuous production, increasing the number of multiple monomers and preparation steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

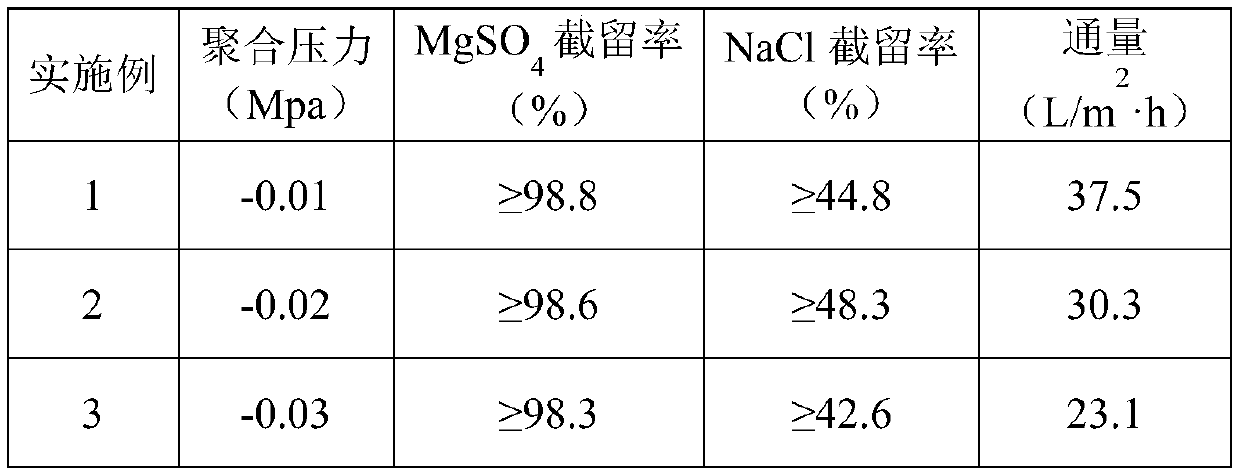

Embodiment 1-3

[0026] A 30,000 molecular weight cut-off ultrafiltration membrane made of polyethersulfone material is selected as the base membrane, and a nanostructured composite membrane is prepared according to the steps described in claim 1:

[0027] (1) prepare the aqueous phase monomer solution, the sulfhydryl concentration in the aqueous phase is 0.50mol / L, the content of bispiperidine in the aqueous phase is 0.40%, and mix uniformly by magnetic stirring;

[0028] (2) preparing an organic phase monomer solution, the content of trimesoyl chloride (TMC) in the organic phase is 0.20%, and the solvent is n-hexane;

[0029] (3) Interfacial polymerization reaction, under the pressure of 0.1Mpa, impregnate the base film in the prepared water phase monomer solution for 4 minutes, pour out the water phase solution, remove the excess liquid on the surface, and then impregnate the base film in the Put in the prepared organic phase monomer solution for 60 seconds, pour out the organic phase solut...

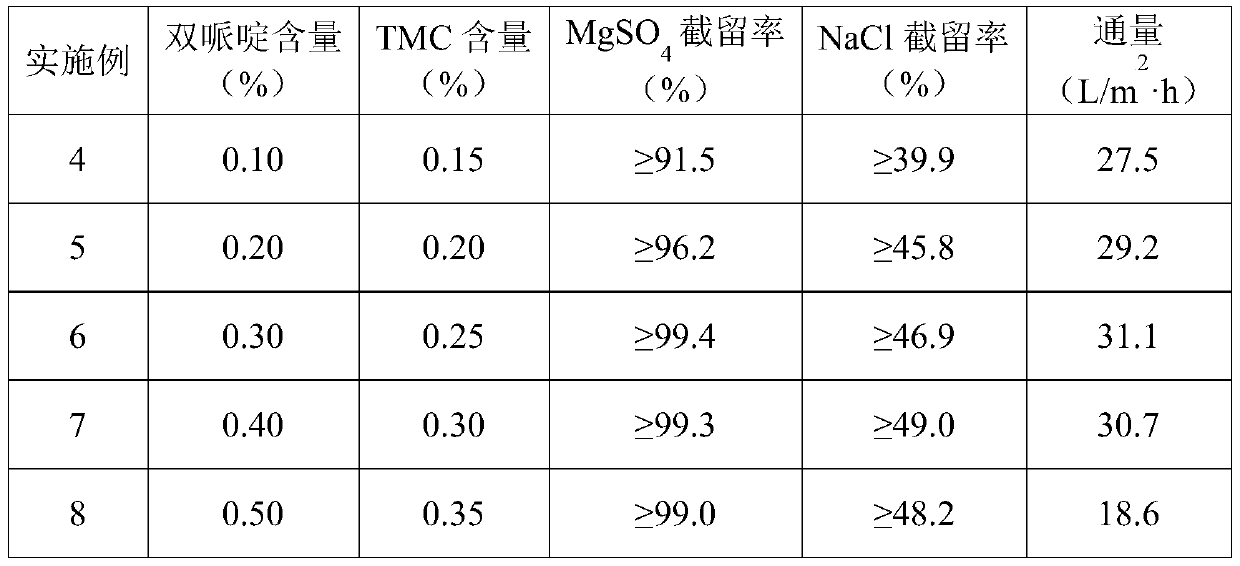

Embodiment 4-8

[0033] The 30000 molecular weight cut-off ultrafiltration membrane made of polysulfone material is selected as the base membrane, and the nanostructure composite membrane is prepared according to the steps described in claim 1:

[0034] (1) prepare aqueous phase monomer solution, the bicarbonate concentration in the aqueous phase is 0.50mol / L, the content of the bispiperidine in the aqueous phase is successively 0.10%, 0.20%, 0.30%, 0.40%, 0.50%, Mix evenly by magnetic stirring;

[0035] (2) prepare organic phase monomer solution, trimesoyl chloride content is as shown in table 2 in the organic phase, and solvent is IsoparG;

[0036] (3) Interfacial polymerization reaction, under 0.1Mpa pressure, impregnate the base film in the prepared water phase monomer solution for 5 minutes, then pour out the water phase solution, remove the excess liquid on the surface, and then impregnate the base film in the prepared water phase monomer solution Put in the good organic phase monomer s...

Embodiment 9-13

[0040] The 30000 molecular weight cut-off ultrafiltration membrane made of polysulfone material is selected as the base membrane, and the nanostructure composite membrane is prepared according to the steps described in claim 1:

[0041] (1) prepare aqueous phase monomer solution, the carbonate group in the water phase and the sulfite group mixing concentration are respectively 0.10,0.20,0.30,0.40,0.50mol / L, the content of the bispiperidine in the water phase is 0.40%, Mix evenly by magnetic stirring;

[0042] (2) preparing an organic phase monomer solution, the content of trimesoyl chloride in the organic phase is 0.20%, and the solvent is n-hexane;

[0043] (3) Interfacial polymerization reaction, immerse the base film in the prepared aqueous phase monomer solution for 5 minutes, pour out the aqueous phase solution, remove excess liquid on the surface, and then impregnate the base film in the prepared organic phase monomer solution In the body solution for 120 seconds, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com