Self-expanding composite bone cement and preparation method thereof

A bone cement and self-expanding technology, which is applied in the preparation of the composite bone cement and in the field of self-expanding composite bone cement, can solve the problems of low expansion rate of bone cement, low expansion rate of bone cement, uneven expansion effect, etc. The effect of water absorption time, improvement of mechanical properties, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

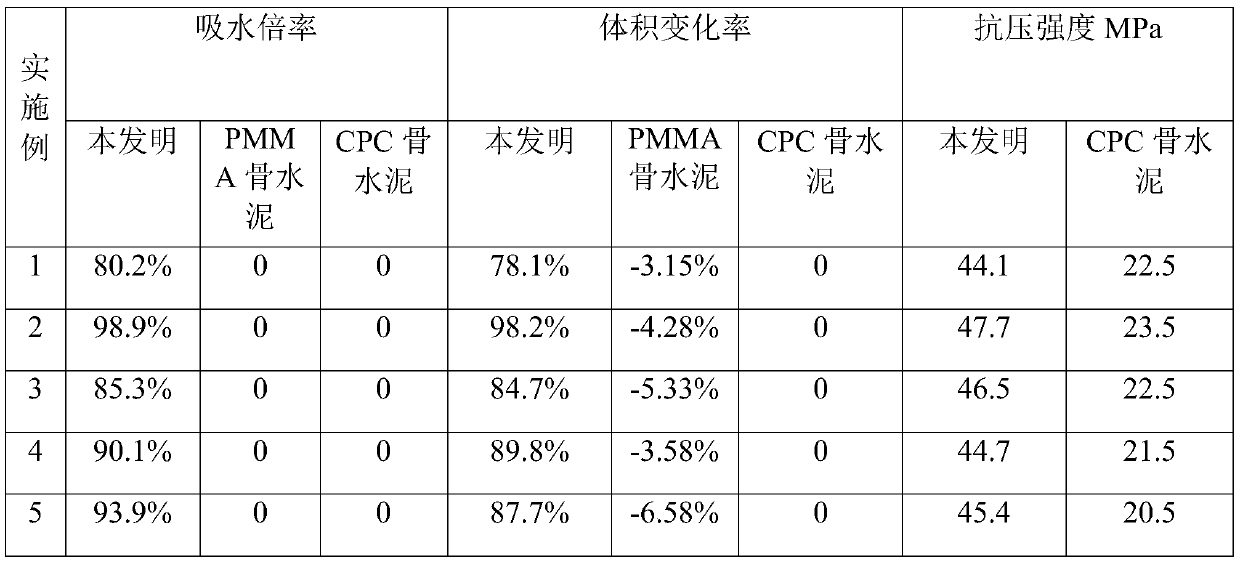

Examples

preparation example Construction

[0033] A preparation method of self-expanding composite bone cement, specifically comprising the following steps:

[0034] Step 1, preparing polymethyl methacrylate-acrylic acid-anhydrous calcium hydrogen phosphate copolymer microspheres;

[0035] Step 2, preparing the solid phase of the self-expanding composite bone cement: tetracalcium phosphate, anhydrous calcium hydrogen phosphate and the polymethyl methacrylate-acrylic acid-anhydrous calcium hydrogen phosphate copolymer microspheres prepared in step 1 as required Mix evenly in proportion to obtain the solid phase of self-expanding composite bone cement;

[0036] Step 3, the solid phase of the self-expanding composite bone cement obtained in step 2 is 1g:1.5ml~1g:7.2ml according to the solid-liquid ratio, and the liquid phase components are evenly mixed and stirred for 20min~90min, and the bone cement is solidified after injection, and the self-expanding composite bone cement is obtained. Expandable composite bone cement. ...

Embodiment 1

[0049] Step 1, the preparation of PMMA-PAA-PDCPA copolymer microspheres:

[0050] Adopt solution polymerization method to prepare PMMA-PAA-PDCPA copolymer: methyl methacrylate (MMA) and acrylic acid (AA) add 0.1wt% hydroquinone underpressure distillation to remove polymerization inhibitor before use; React in four-necked flask Carry out, four ports in the four-neck flask are respectively connected with nitrogen, magnetic stirring rod, condenser, thermometer; respectively take methyl methacrylate (MMA) 5.622%, acrylic acid (AA) 15.323% after decompression distillation, anhydrous phosphoric acid Hydrogen calcium (DCPA) 0.364%, crosslinking agent N, N methylenebisacrylamide (MBA) 1.457%, dispersant polyvinylpyrrolidone (PVP) 2.127%, initiator azobisisobutyronitrile (AIBN) 0.607% , deionized water 74.5%, total 100%;

[0051] Add MMA, AA and DCPA, cross-linking agent MBA solution, dispersant PVP solution, and initiator AIBN solution into a four-necked flask in sequence and mix eve...

Embodiment 2

[0055] Step 1, the preparation of PMMA-PAA-PDCPA copolymer microspheres:

[0056] Prepare PMMA-PAA-PDCPA copolymer by solution polymerization: Methyl methacrylate (MMA) and acrylic acid (AA) add 1.5wt% hydroquinone to remove polymerization inhibitor under reduced pressure before use. The reaction was carried out in a four-necked flask, and the four ports of the four-necked flask were respectively connected with nitrogen, a magnetic stirring bar, a condenser tube, and a thermometer; respectively, 19.589% of methyl methacrylate (MMA) and acrylic acid (AA) after decompression distillation were taken. 4.700%, anhydrous calcium hydrogen phosphate (DCPA) 0.061%, crosslinking agent N, N methylenebisacrylamide (MBA) 0.972%, dispersant polyvinylpyrrolidone (PVP) 1.214%, initiator azobisisobutyl Nitrile (AIBN) 0.243%, deionized water 73.221%, total 100%;

[0057] Add MMA, AA and DCPA, cross-linking agent MBA solution, dispersant PVP solution, and initiator AIBN solution into a four-nec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com