Preparation method of green tea powder rich in dietary fibers

A technology of dietary fiber and green tea powder, which is applied in tea treatment before extraction, etc., can solve problems such as difficult temperature control, low water content, tea damage, etc., and achieve the effect of promoting the increase of ice crystals, high water content, and promoting recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

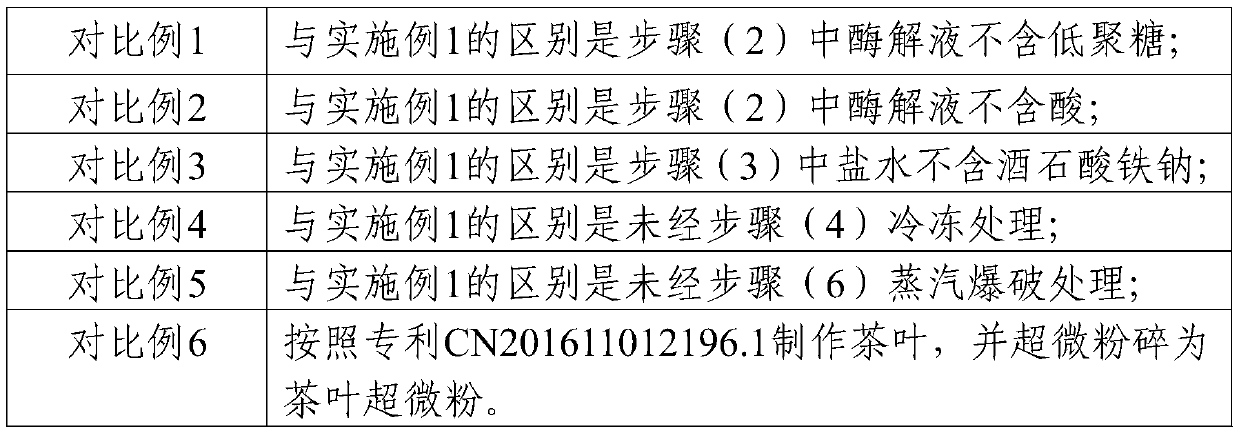

Examples

Embodiment 1

[0031] A preparation method rich in dietary fiber green tea powder, comprising the following steps:

[0032] (1) cleaning

[0033] Wash the freshly picked tea leaves in clean water at -15°C, drain the water for later use; the washing time is 10 minutes;

[0034] (2) Enzymolysis

[0035] Spread the tea leaves in a cooling room at 28°C, with a thickness of 1cm, spray the enzymatic solution on the surface of the tea leaves, let it cool for 2 hours, turn the tea leaves, turn the tea leaves underneath to the surface, spray the enzymatic solution again, and let it cool for 3 hours The air pressure of the cooling room is 1 standard atmospheric pressure, and the humidity is 65%; in parts by mass, the preparation method of the enzymolysis solution is as follows: 1 part of acid, 2 parts of cellulase, 3 parts of pectinase, low Mix 1 part of polysaccharide and 110 parts of deionized water evenly, heat to 35°C for later use; the acid is citric acid; the amount of the enzymolysis solution...

Embodiment 2

[0047] A preparation method rich in dietary fiber green tea powder, comprising the following steps:

[0048] (1) cleaning

[0049] Wash the freshly picked tea leaves in clean water at -15°C, drain the water for later use; the washing time is 15 minutes;

[0050] (2) Enzymolysis

[0051] Spread the tea leaves in a cooling room at 32°C, with a thickness of 2cm, spray the enzymatic hydrolysis solution on the surface of the tea leaves, let it cool for 3 hours, turn the tea leaves over, turn the bottom tea leaves to the surface, spray the enzymatic solution again, and let it cool for 5 hours The air pressure of the cooling room is 1.5 standard atmospheric pressure, and the humidity is 75%; in parts by mass, the preparation method of the enzymolysis solution is as follows: 3 parts of acid, 3 parts of cellulase, 5 parts of pectinase, low Mix 2 parts of polysaccharide and 120 parts of deionized water evenly, heat to 38°C for later use; the acid is acetic acid; the amount of the enzy...

Embodiment 3

[0063] A preparation method rich in dietary fiber green tea powder, comprising the following steps:

[0064] (1) cleaning

[0065]Wash the freshly picked tea leaves in clean water at -15°C, drain the water for later use; the cleaning time is 13 minutes;

[0066] (2) Enzymolysis

[0067] Spread the tea leaves in a cooling room at 29°C, with a thickness of 2cm, spray the enzymatic hydrolysis solution on the surface of the tea leaves, let it cool for 2 hours, turn the tea leaves over, turn the bottom tea leaves to the surface, spray the enzymatic hydrolysis solution again, and let it cool for 5 hours The air pressure of the cooling room is 1 standard atmospheric pressure, and the humidity is 75%; in parts by mass, the preparation method of the enzymolysis solution is as follows: 1 part of acid, 3 parts of cellulase, 3 parts of pectinase, low Mix 2 parts of polysaccharide and 110 parts of deionized water evenly, heat to 38°C for later use; the acid is mixed with citric acid and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com