Bismuth selenide oxide nanosheet photoelectric detector treated by oxygen plasma and preparation method

An oxygen plasma and photodetector technology, applied in semiconductor devices, circuits, electrical components, etc., can solve the problems of low carrier mobility, limited application range, non-uniform material properties, and low responsivity, etc. The effect of popularization and application, low cost and high switching ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

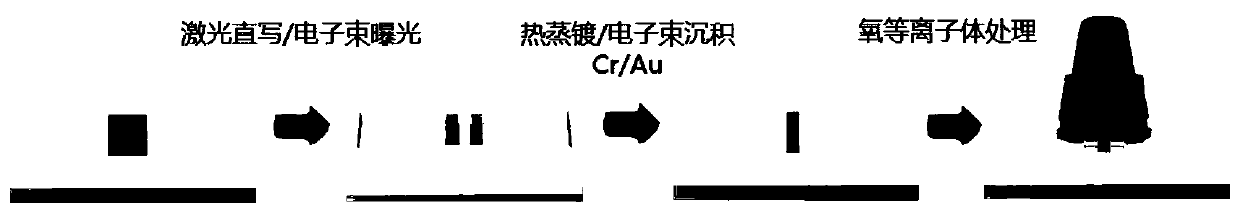

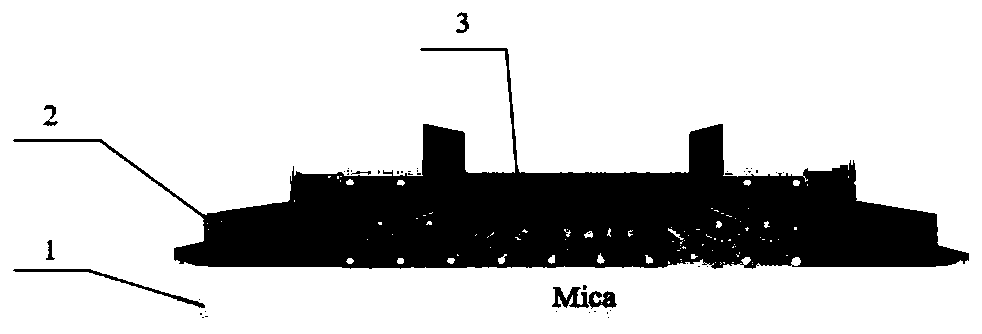

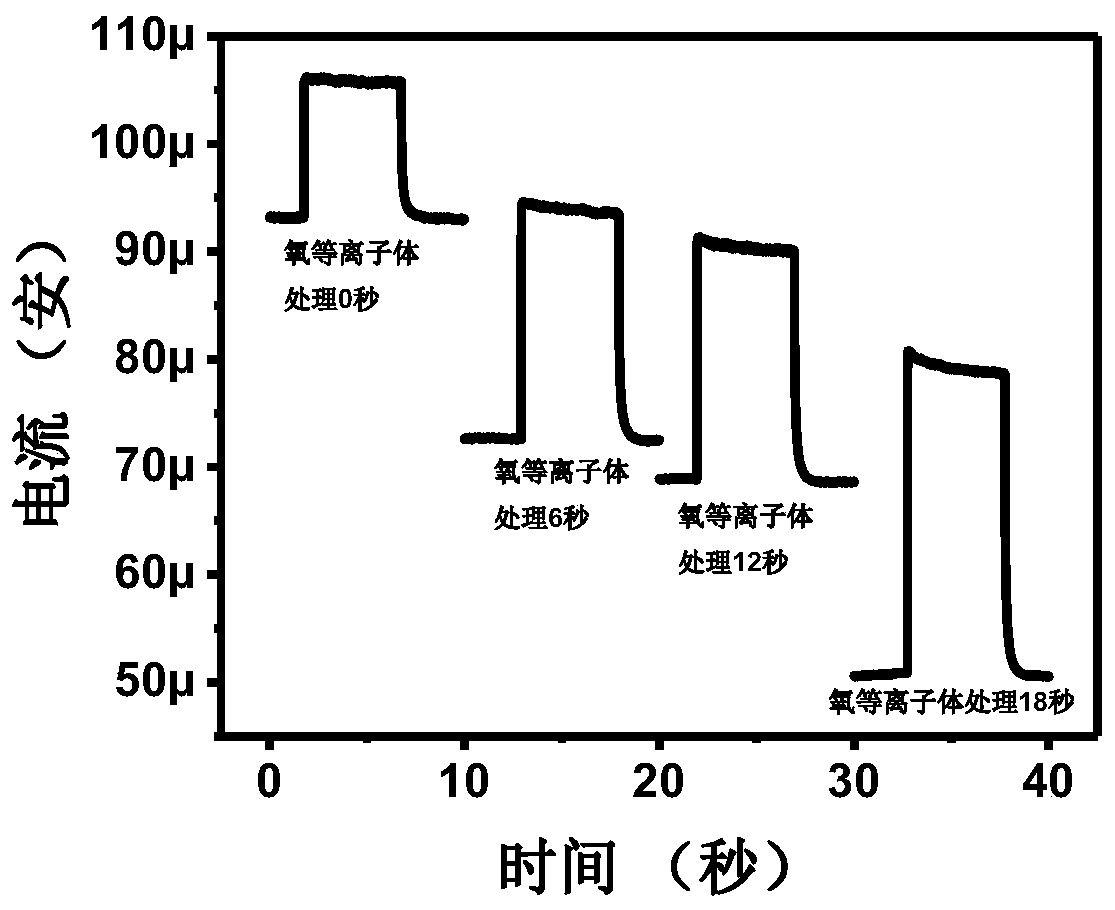

[0030] see figure 1 and figure 2 , the preparation method of the bismuth selenium oxide nanosheet photodetector that the oxygen plasma treatment provided by the present invention mainly comprises the following steps:

[0031] Step 1, preparing bismuth selenium oxide nanosheets on the substrate by chemical vapor deposition.

[0032] In this embodiment, the substrate is an insulating material, which is a mica sheet; the thickness of the bismuth selenium oxide nanosheet is 10nm-100nm, and its shape is a square.

[0033] Step 2, using laser direct writing or electron beam exposure technology, combined with thermal evaporation and electron beam evaporation technology to prepare a pair of source-drain metal electrodes on the bismuth selenium oxide nanosheet.

[0034] In this embodiment, the source-drain metal electrode is a chromium-gold composite electrode, wherein the thickness of chromium is 5nm-10nm, and the thickness of gold is 50nm-100nm.

[0035] Specifically, a metal ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com