Three-dimensional porous MXene/graphene composite membrane and preparation method and application thereof

A graphene composite, three-dimensional porous technology, applied in the field of electrode materials, can solve the problems of slow construction, increased cost, and decreased material performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

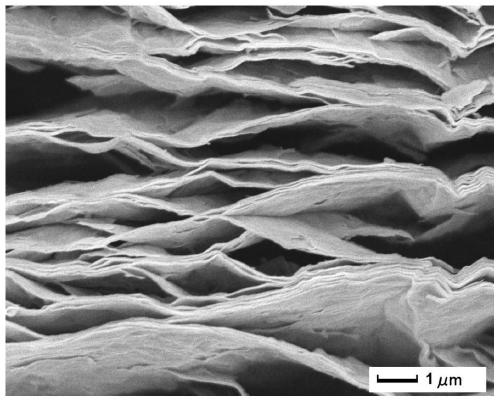

[0032] The invention provides a kind of preparation method of three-dimensional porous MXene / graphene composite membrane, comprises the following steps:

[0033] Provide the dispersion liquid of single-layer MXene and the dispersion liquid of single-layer graphene oxide;

[0034] After mixing the dispersion of single-layer MXene and the dispersion of single-layer graphene oxide, the obtained mixed dispersion is formed into a film to obtain a MXene / graphene oxide composite film;

[0035] The MXene / graphene oxide composite membrane is subjected to a self-propagating reduction reaction to obtain a three-dimensional porous MXene / graphene composite membrane.

[0036] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0037] The invention provides a dispersion liquid of single-layer MXene and a dispersion liquid of single-layer graphene oxide. In the present invention, the ...

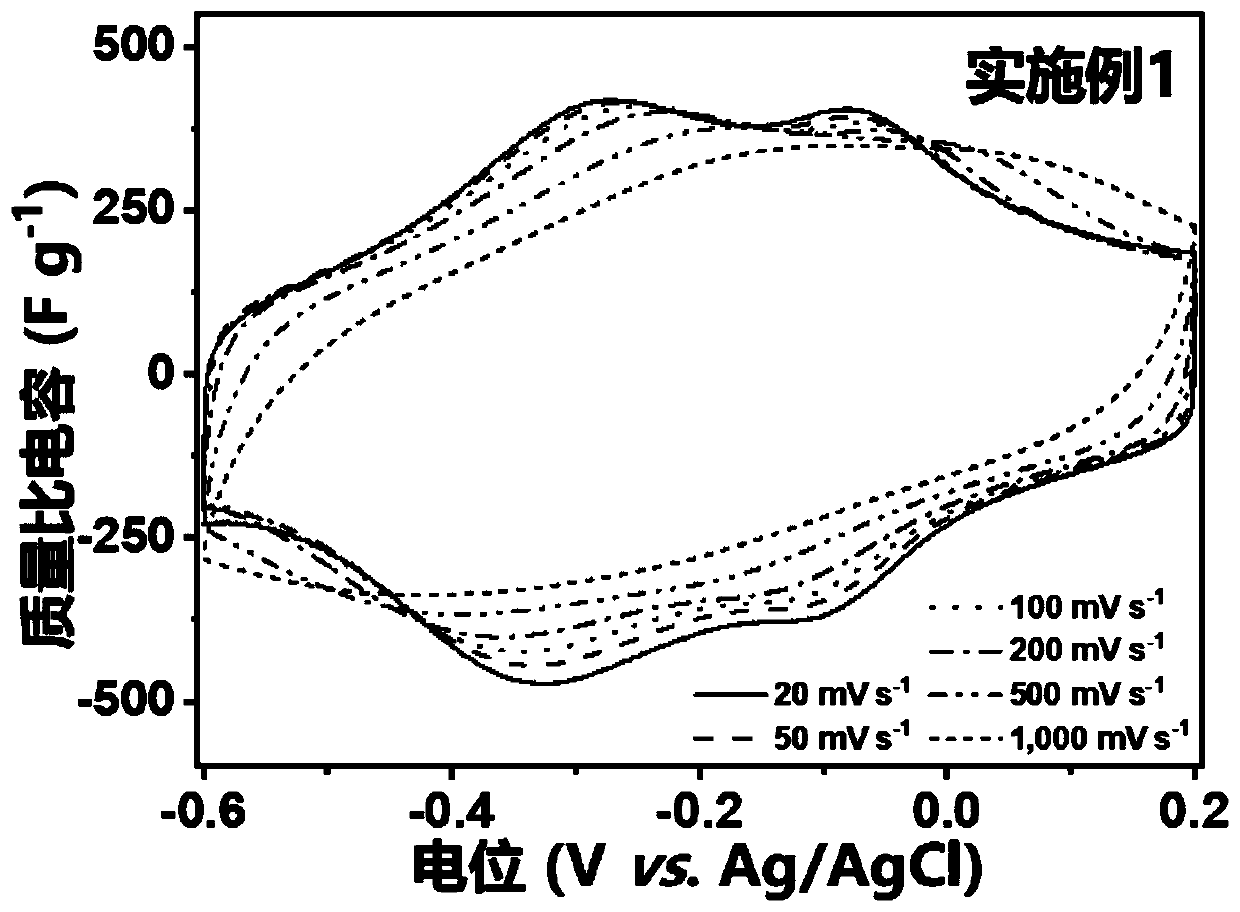

Embodiment 1

[0072] (1) Preparation of a dispersion of monolamellar MXene

[0073] Mix 2gLiF with 20mL hydrochloric acid with a mass concentration of 9mol / L, and stir at a speed of 60r / min for 10min to obtain an etching solution;

[0074] 2 g of Ti with an average particle size of 50 μm 3 AlC 2 Mix with the etchant, after ultrasonic 5min under the power of 600W, the Ti 3 AlC 2 The mixture with the etching solution was placed in a constant temperature water bath at 35°C, and stirred and reacted at a speed of 60r / min for 24h; , the time is 10min), repeat the operation 8 times, pour off the supernatant to obtain MXene;

[0075] Mix 100 mg MXene with 100 mL deionized water, sonicate at 600 W for 30 min, centrifuge at 3000 relative centrifugal force for 1 h, collect the upper layer solution, and obtain a 1 mg / mL single-layer MXene dispersion.

[0076] (2) Preparation of a dispersion of monolithic graphene oxide

[0077] After mixing 3.5 g of graphite powder with an average particle size o...

Embodiment 2

[0086] (1) Preparation of a dispersion of monolamellar MXene

[0087] Mix 2gLiF with 20mL of hydrochloric acid with a mass concentration of 12mol / L, and stir at a speed of 90r / min for 10min to obtain an etching solution;

[0088] 2 g of Ti with an average particle size of 50 μm 3 AlC 2 Mix with the etchant, after ultrasonic 5min under the power of 600W, the Ti 3 AlC 2The mixture with the etching solution was placed in a constant temperature water bath at 35°C, and stirred and reacted at a speed of 90r / min for 24h; , the time is 10min), repeat the operation 8 times, pour off the supernatant to obtain MXene;

[0089] Mix 100mg of MXene with 100mL of deionized water, sonicate for 20min at a power of 600W, centrifuge at a relative centrifugal force of 3000 for 1h, collect the upper layer solution, and obtain a 1mg / mL single-layer MXene dispersion.

[0090] (2) Preparation of a dispersion of monolithic graphene oxide

[0091] After mixing 3.5 g of graphite powder with an aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com