A method for enriching platinum and co-producing metallic aluminum from spent alumina platinum catalyst

A platinum catalyst, alumina technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal chlorides, etc., can solve the problems of loss of value of carrier aluminum oxide, low content of platinum group metals, etc., and achieve industrial application prospects Broad, high platinum yield, good enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

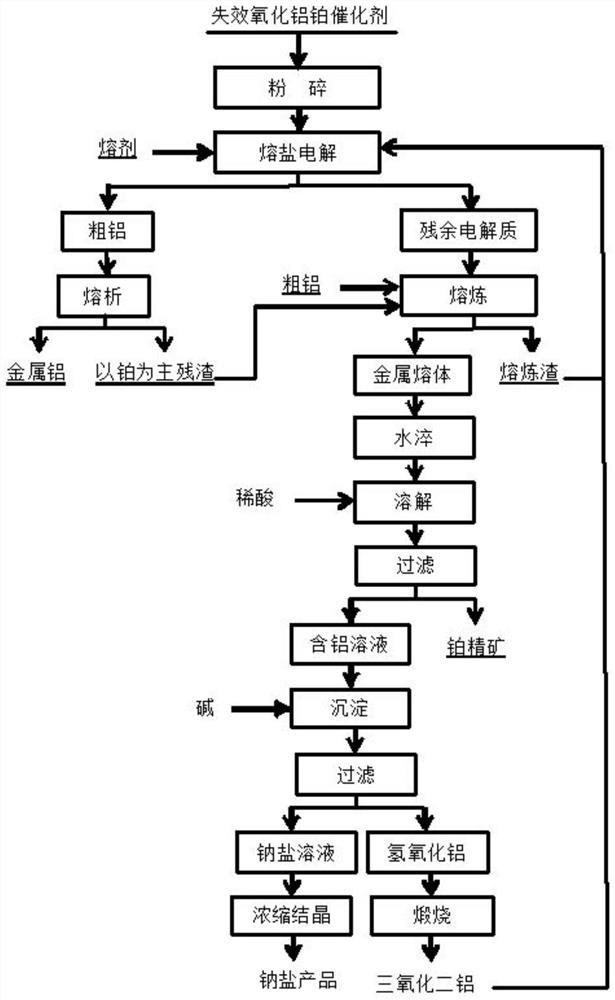

[0036] Embodiment 1-7 A process flow diagram of a method for enriching platinum and co-producing metallic aluminum from spent alumina platinum catalysts is as follows figure 1 shown.

Embodiment 1

[0038] A method for enriching platinum and co-producing metallic aluminum from spent alumina platinum catalyst, said method comprising the steps of:

[0039] S1. Mix the exhausted alumina platinum catalyst with flux, and place it in an aluminum electrolytic cell for electrolytic reaction. The parameters of the electrolytic reaction are: cell operating voltage 4.2V, electrolysis temperature 980°C, pole distance 5cm, molecular ratio 2.6, alumina content 4%, electrolyte level 23cm, aluminum liquid level 20cm, anode current density 0.62A / cm 2 , the flux is 85% cryolite, 2% aluminum fluoride, and 3% sodium fluoride to obtain crude aluminum and residual electrolyte respectively, and part of the residual electrolyte is returned to the aluminum electrolytic cell for electrolytic reaction;

[0040] S2. Raise the temperature of the crude aluminum to 670°C and stir it mechanically for 2 hours. The platinum-aluminum intermetallic compound is precipitated in a solid state to form an infusi...

Embodiment 2

[0045] A method for enriching platinum and co-producing metallic aluminum from spent alumina platinum catalyst, said method comprising the steps of:

[0046] S1. Mix the exhausted alumina platinum catalyst with flux and place it in an aluminum electrolytic cell for electrolytic reaction. The parameters of the electrolytic reaction are: cell operating voltage 4.2V, electrolysis temperature 960°C, pole distance 4cm, molecular ratio 2.3, alumina content 3%, electrolyte level 21cm, aluminum liquid level 23cm, anode current density 0.65A / cm 2 , the flux is 87% cryolite and 5% aluminum fluoride to obtain crude aluminum and residual electrolyte respectively, and part of the residual electrolyte is returned to the aluminum electrolytic cell for electrolytic reaction;

[0047] S2. Raise the temperature of the crude aluminum to 680°C and use electromagnetic stirring for 1 hour. The platinum-aluminum intermetallic compound is precipitated in a solid state to form an infusible residue, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com