Grain production method for twice thinning by front cutting

A production method and grain technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increasing grain production cost, grain scrapping damage, grain damage, etc., to shorten cutting time, control The effect of reducing production cost and improving the qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for producing grains by front-side cutting twice for thinning, the production method comprising the following steps:

[0049] S1: front cut

[0050] The wafer 1 is cut by means of diamond cutting, and the die 4 is cut from the front side of the die 4 to a position of 1.05X, where X is the estimated final thickness of the wafer 1 after thinning.

[0051] S2: fixed once

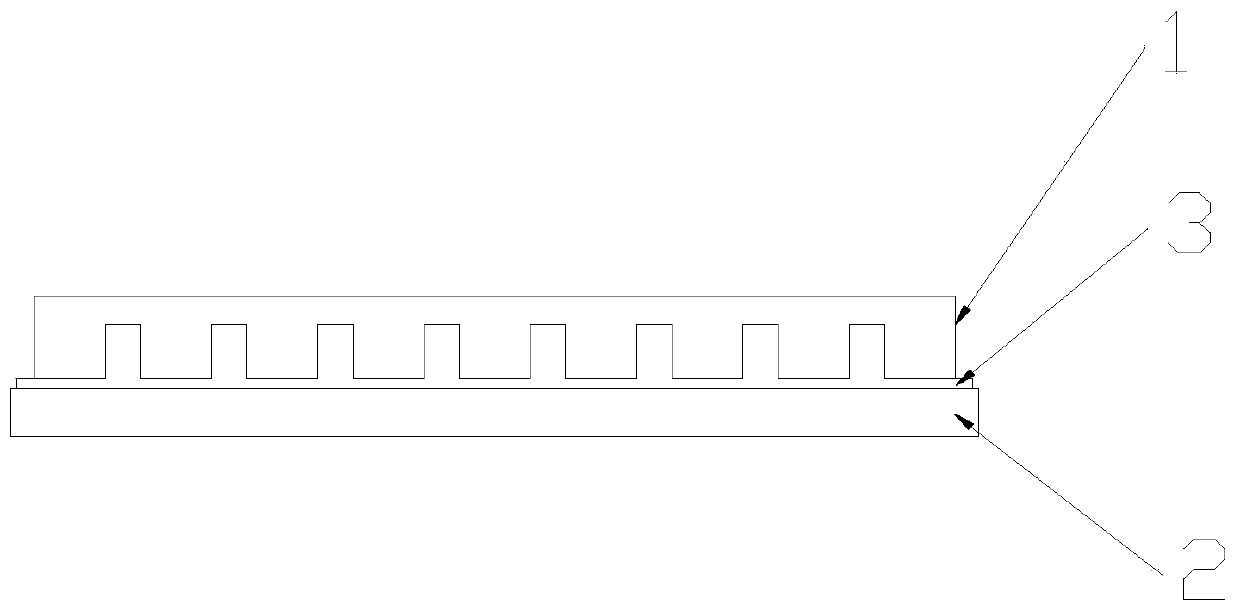

[0052] Use adhesive 3 to bond the cut front side of wafer 1 on glass carrier 2, such as figure 1 As shown, the adhesive 3 bonds the wafer 1 and the glass carrier 2 together by UV bonding, the temperature requirement is 50-200° C., and the use time is less than 30 minutes.

[0053] S3: one thinning

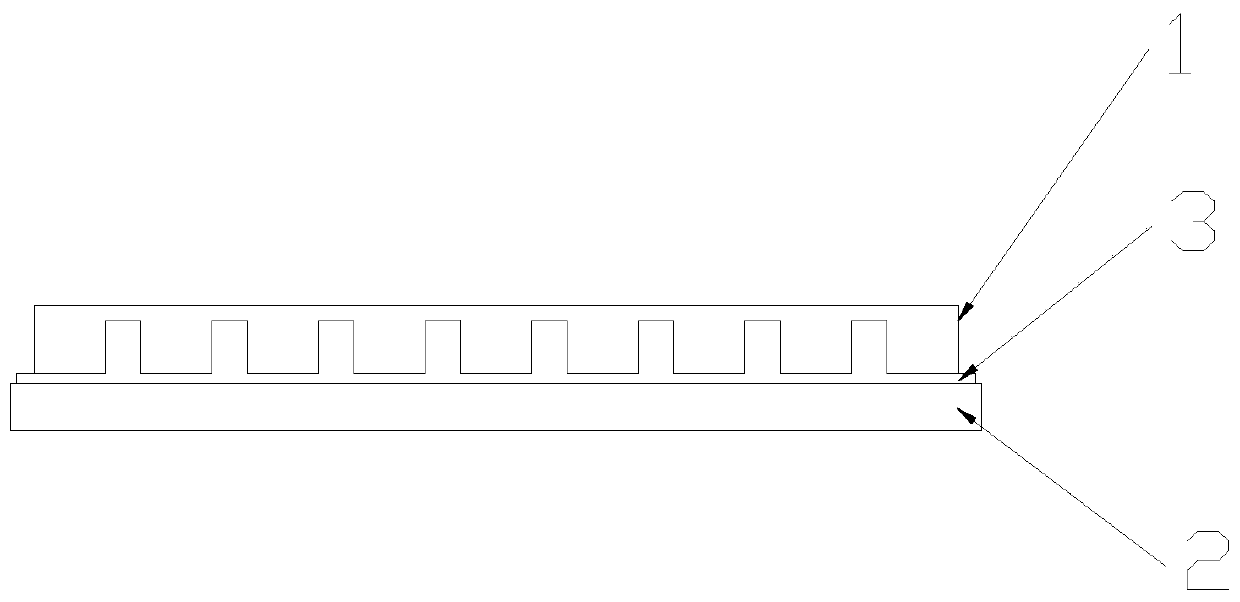

[0054] Thinning the cut backside by grinding, such as figure 2 As shown, the thickness of one thinning is 1.01Y, Y=1.05X.

[0055] S4: intermediate process

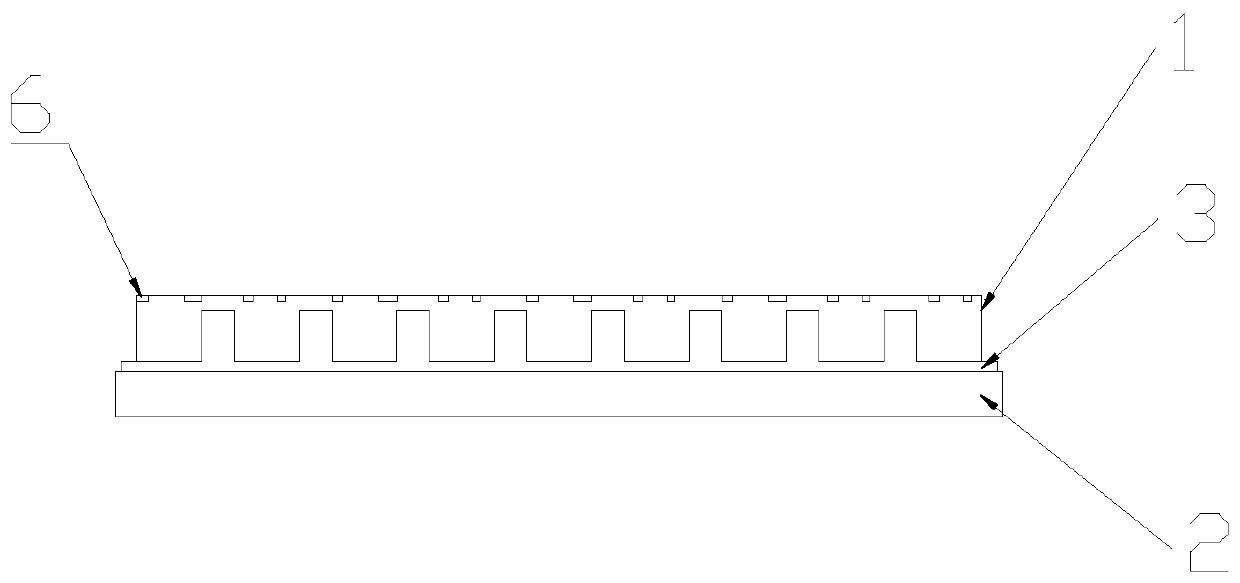

[0056] Yellow light on the back side, ion implantation, ion implantation layer 6 is formed on the back side of the crystal grain 4, such...

Embodiment 2

[0070] A method for producing grains by front-side cutting twice for thinning, the production method comprising the following steps:

[0071] S1: front cut

[0072] The wafer 1 is cut by laser cutting, and the die 4 is cut from the front side of the die 4 to a position of 1.2X, where X is the estimated final thickness of the wafer 1 after thinning.

[0073] S2: fixed once

[0074]Use the adhesive 3 to bond the cut front of the wafer 1 to the glass carrier 2. The adhesive bonds the wafer 1 and the glass carrier 2 together by heating and bonding. The temperature requirement is 150-300°C. The time of use is 30 minutes or less.

[0075] S3: one thinning

[0076] Thinning is performed on the cut back side by etching, and the thickness of the first thinning is 1.1Y, Y=1.2X.

[0077] S4: intermediate process

[0078] Backside yellow light, ion implantation, ion implantation layer 6 is formed on the backside of crystal grain 4, photoresist removal, annealing process.

[0079] S5...

Embodiment 3

[0092] A method for producing grains by front-side cutting twice for thinning, the production method comprising the following steps:

[0093] S1: front cut

[0094] The wafer 1 is cut by means of plasma cutting, and the die 4 is cut from the front side of the die 4 to a position of 1.3X, where X is the estimated final thickness of the wafer 1 after thinning.

[0095] S2: fixed once

[0096] Use the adhesive 3 to bond the cut front of the wafer 1 to the glass carrier 2. The adhesive 3 bonds the wafer 1 and the glass carrier 2 together by heating and bonding, and the temperature requirement is 150-300°C , the use time is less than 30 minutes.

[0097] S3: one thinning

[0098] Thinning is performed on the cut back surface by etching, and the thickness of the first thinning is 1.2Y, Y=1.3X.

[0099] S4: intermediate process

[0100] Backside yellow light, ion implantation, ion implantation layer 6 is formed on the backside of crystal grain 4, photoresist removal, annealing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com