Preparation method of vegetable oil modified polymer polyether defoamer

A technology for polymer polyether and vegetable oil modification, which is applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve problems such as immediate combustion and serious environmental hazards, and achieve low production costs, good stability, Effect of good spreading properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

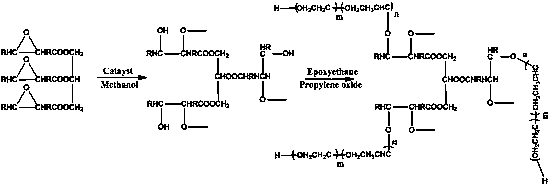

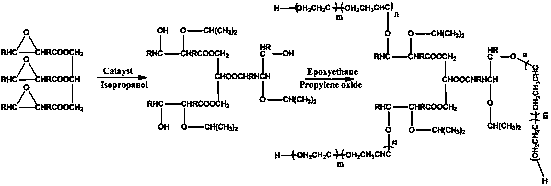

Image

Examples

Embodiment 1

[0030] 1. Preparation method of Lewis acid-base pair catalyst

[0031] Composed of tris(dimethylamino)phosphorus and triethylboron, the molar ratio of tris(dimethylamino)phosphorus and triethylboron is 1:3; the preparation method of tris(dimethylamino)phosphorus is as follows:

[0032] (1) Add phosphorus trichloride (13.73 g, 0.1 mol, 1.0 equiv.) into a 500 mL three-necked flask equipped with a stirring magnet, add 50 mL of anhydrous dichloromethane under nitrogen protection, and place at -40 o C low temperature, keep stirring vigorously;

[0033] (2) Continuously feed excess gas of dimethylamine into the reaction system to maintain the solution temperature at -30 o After reacting below C for 1 h, stop feeding dimethylamine gas;

[0034] (3) After the reaction system dropped to room temperature, it was stirred for another 3 h, and the solvent was distilled off under reduced pressure to obtain a colorless solution, namely tris(dimethylamino)phosphorus.

[0035] 2. Preparatio...

Embodiment 2

[0039] 1. Preparation method of Lewis acid-base pair catalyst

[0040] With embodiment 1.

[0041] 2. Preparation method of rapeseed oil modified polymer polyether defoamer

[0042] (1) Under nitrogen protection, add methanol (5.5 g, 0.17 mol), tris(dimethylamino)phosphorus (1.6 g, 10.0 mmol) and triethylboron (29.4 g, 30.0 mmol) into a 1000 mL reaction flask , after stirring for 10 min, epoxy rapeseed oil (700 g) was added and reacted at room temperature for 2 h. Carry out decompression distillation to remove methanol in the reaction flask after the reaction, to obtain a mixture containing catalyst and rapeseed oil polyol initiator;

[0043](2) After repeated nitrogen replacement of the reaction flask containing the catalyst and rapeseed oil polyol initiator, propylene oxide (266 g, 4.59 mol) and ethylene oxide (150 g, 3.4 mol) were injected into the reactor ), reacted at room temperature for 12 h. After the reaction is finished, add a certain amount of acetic acid into t...

Embodiment 3

[0045] 1. Preparation method of Lewis acid-base pair catalyst

[0046] With embodiment 1.

[0047] 2. Preparation method of castor oil modified polymer polyether defoamer

[0048] (1) Under nitrogen protection, add methanol (5.5 g, 0.17 mol), tris(dimethylamino)phosphorus (1.6 g, 10.0 mmol) and triethylboron (29.4 g, 30.0 mmol) into a 1000 mL reaction flask , after stirring for 10 min, epoxy castor oil (500 g) was added and reacted at room temperature for 2 h. Carry out decompression distillation to remove methyl alcohol with the reaction bottle after reaction finishes, obtain the mixture containing catalyst and castor oil polyol initiator;

[0049] (2) After repeated nitrogen replacement of the reaction flask containing the catalyst and castor oil polyol initiator, propylene oxide (266 g, 4.59 mol) and ethylene oxide (150 g, 3.4 mol) were injected into the reactor respectively , reacted at room temperature for 12 h. After the reaction is over, add a certain amount of acet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com