A kind of anti-smoke oil degeneration material and its preparation method and application, atomization device

An atomizing device, oil deterioration technology, applied in applications, glass manufacturing equipment, tobacco, etc., can solve the problem of easy deterioration of e-liquid, and achieve the effect of wide wavelength range, variable wavelength range, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

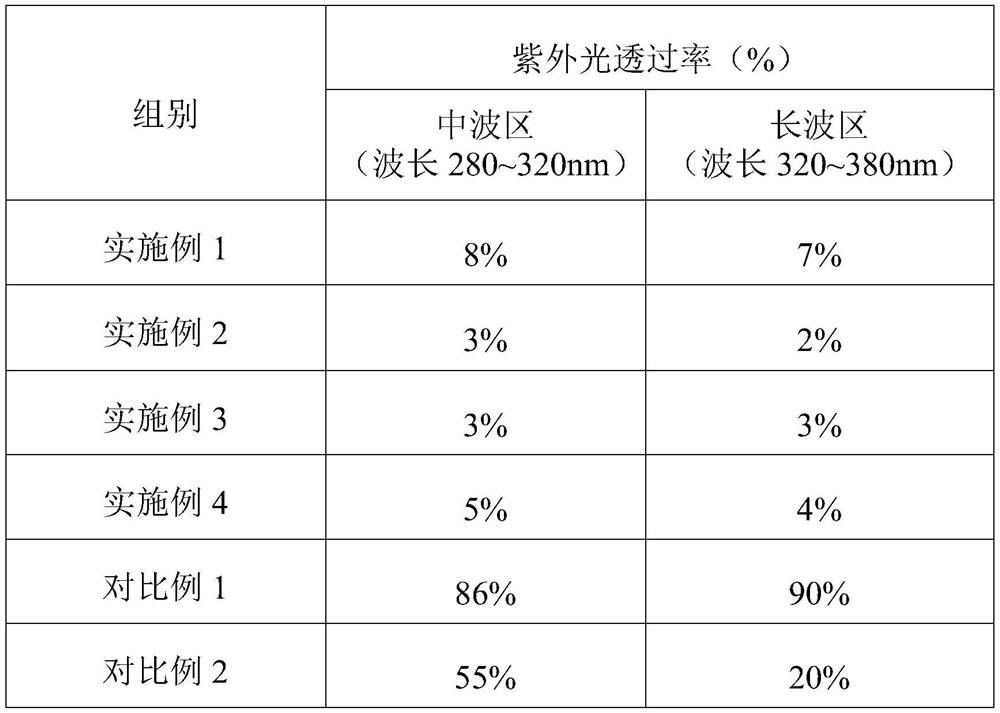

Embodiment 1

[0035] A material for preventing smoke oil deterioration, characterized in that it comprises the following raw materials in parts by weight: 80 parts of silicon dioxide, 6 parts of soda ash, 2 parts of alumina, 8 parts of limestone, 2 parts of boric acid, 1 part of sodium antimonate, and 15 parts of titanium dioxide , 7 parts of zinc oxide.

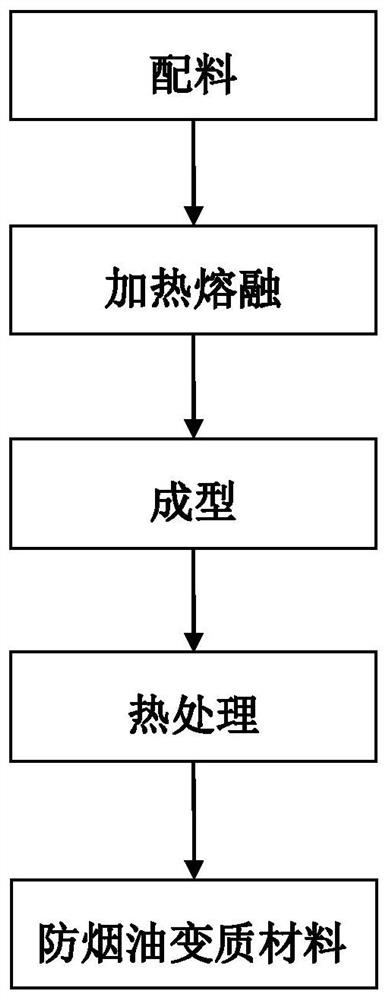

[0036] This embodiment provides the preparation method of the anti-smoke oil deterioration material, the specific process is as follows figure 1 described, including the following steps:

[0037] (1) Ingredients: The raw material powder is pulverized and mixed by ball milling to obtain a mixture, the ball milling speed is 400r / min, and the ball milling time is 12h;

[0038] (2) Heating and melting: the mixture in step (1) is heated and melted, the heating rate is 4°C / min, the temperature is 1200°C, the holding time is 2h, clarification, homogenization, and discharge of bubbles to obtain glass liquid;

[0039] (3) Molding: Pour the molte...

Embodiment 2

[0045] A material for preventing smoke oil deterioration, characterized in that it comprises the following raw materials in parts by weight: 80 parts of silicon dioxide, 6 parts of soda ash, 2 parts of alumina, 8 parts of limestone, 2 parts of boric acid, 1 part of sodium antimonate, and 15 parts of titanium dioxide , 7 parts of zinc oxide.

[0046] Titanium dioxide is modified titanium dioxide, and the preparation method of modified titanium dioxide comprises the following steps:

[0047] ① Add cerium nitrate, deionized water, absolute ethanol and acetic acid into the reaction vessel in turn, and stir and mix; for every 0.001mol of cerium nitrate, the required volume of deionized water is 40ml, the required volume of ethanol is 160ml, and the required volume of acetic acid is 36ml;

[0048] ② Mix butyl titanate and ethanol according to the volume ratio of 10:28 to obtain a mixed solution, and the molar ratio of butyl titanate to cerium nitrate in step ① is 1:0.005;

[0049] ...

Embodiment 3

[0058] A material for preventing smoke oil deterioration, characterized in that it includes the following raw materials in parts by weight: 70 parts of silicon dioxide, 5 parts of soda ash, 3 parts of alumina, 9 parts of limestone, 1 part of boric acid, 0.5 parts of sodium antimonate, and 12 parts of titanium dioxide , 8 parts of zinc oxide.

[0059] Titanium dioxide is modified titanium dioxide, and the preparation method of modified titanium dioxide comprises the following steps:

[0060] ① Add cerium nitrate, deionized water, absolute ethanol and acetic acid into the reaction vessel in turn, stir and mix; for every 0.001mol of cerium nitrate, the required volume of deionized water is 50ml, the required volume of ethanol is 140ml, and the required volume of acetic acid is 40ml;

[0061] ② Mix butyl titanate and ethanol according to the volume ratio of 10:30 to obtain a mixed solution, and the molar ratio of butyl titanate to cerium nitrate in step ① is 1:0.015;

[0062] ③ A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com