Positioning and drilling tool for circular covering cap and using method thereof

A technology for drilling tooling and mouth caps, which is applied in the direction of manufacturing tools, metal processing equipment, and drilling molds for workpieces. Reduce the difficulty of operation and the effect of precise mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

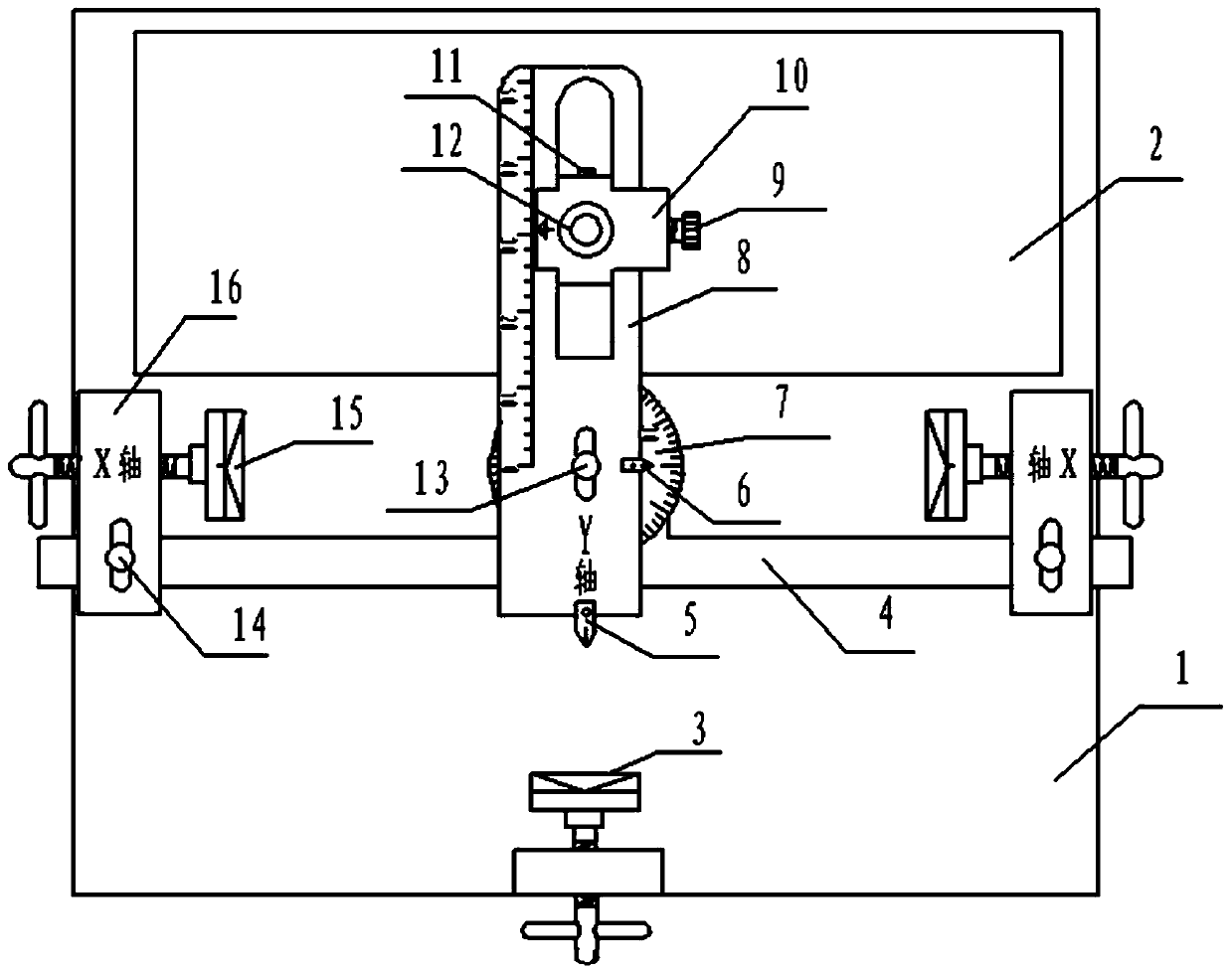

[0029] The device of the present invention is mainly composed of a workpiece positioning platform 1, a rubber pad 2, a longitudinal V-shaped clamping device 3, a horizontal slide rail 4, a Y-axis zero pointer 5, a Y-axis rotation pointer 6, an angle scale disc 7, and a Y-axis sliding bracket 8 , locking screw 9, guide hole positioning block 10, top wire 11, alloy bushing 12, Y-axis sliding guide rail deflection locking device 13, X-axis locking device 14, transverse V-shaped clamping device 15, transverse sliding support 16 components, the structure of each part is as follows figure 1shown. Among them, the workpiece positioning platform 1 is made of high hardness and wear-resistant steel metal material, which mainly provides a mounting and fixing platform for other parts and a later drilling operation platform; the rubber pad 2 is mainly used for protection and buffering. Prevent the drill bit from touching the workpiece positioning platform 1 after the drill bit has just dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com