Three-station automatic multifunctional all-in-one machine for double-layer packaging bags

A double-layer packaging bag and three-station technology, which is applied in the field of packaging bag processing, can solve problems such as poor operability, low production efficiency, and large floor space, and achieve reasonable equipment operation, increased useful power, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

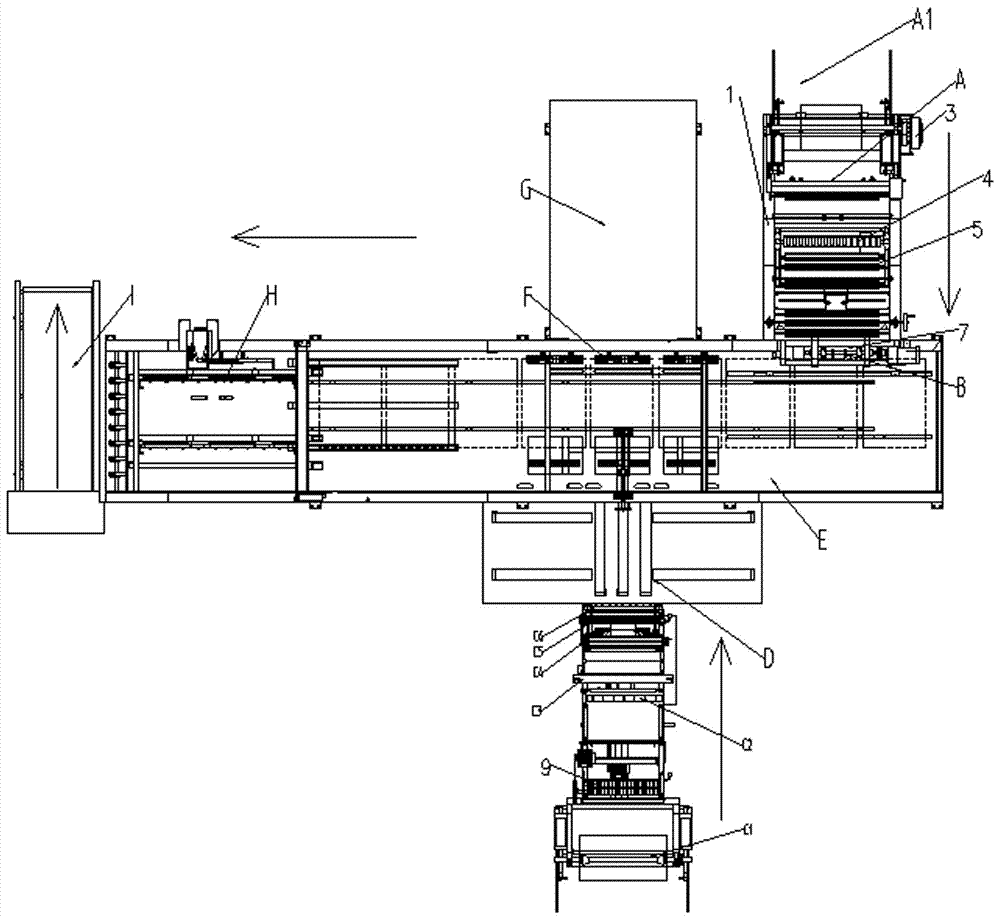

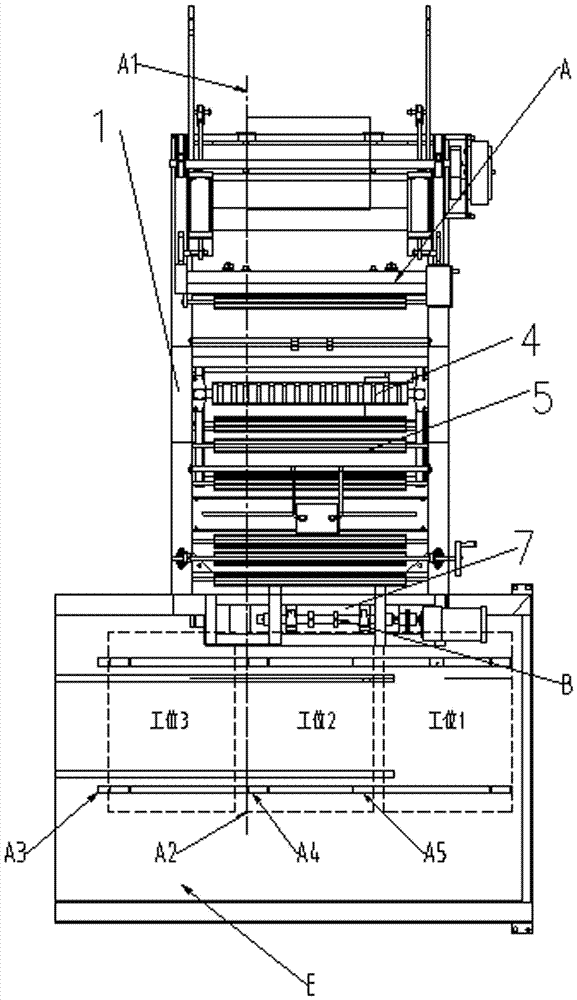

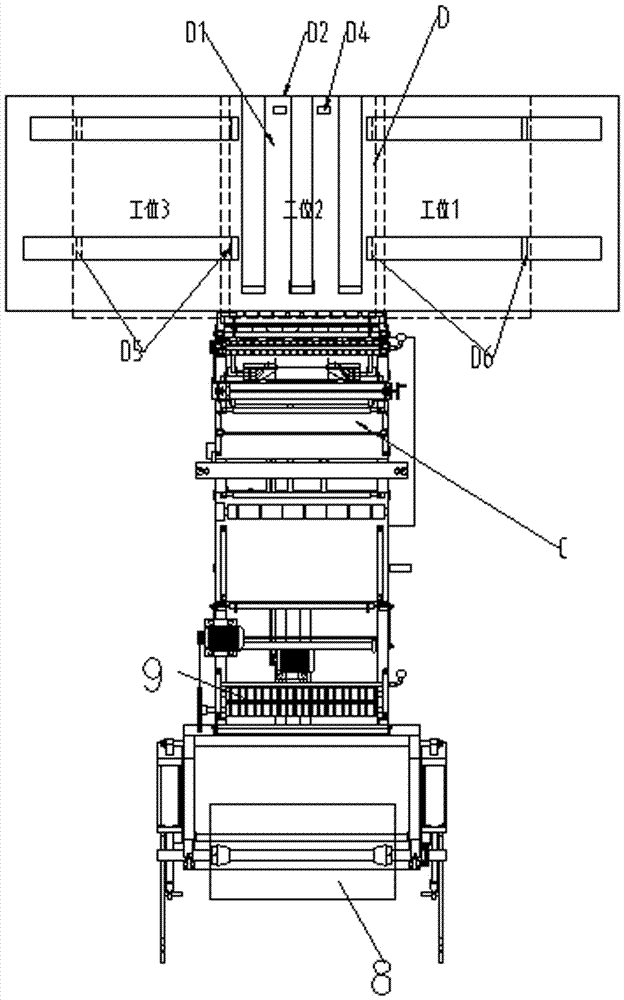

[0031] Such as Figure 1-9 As shown, the present invention is a three-station automatic multifunctional all-in-one machine for double-layer packaging bags. On the front left side of the mechanism E, there is a cylindrical outer bag unwinding mechanism A and a cylindrical outer bag cutting three-station mechanism B, and a high-speed inner film bag making machine C is installed in the middle of the right side of the three-station conveying main mechanism E And inner film bag three-station mechanism D, opposite to the inner film bag three-station mechanism D, and on the left side of the three-station conveying main mechanism E, set the pulling inner bag mechanism G, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com