Base structure of camera

A portable and landline technology, applied to cameras, camera bodies, optics, etc., can solve problems such as unreliable reliability, increased weight and volume, and increased operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

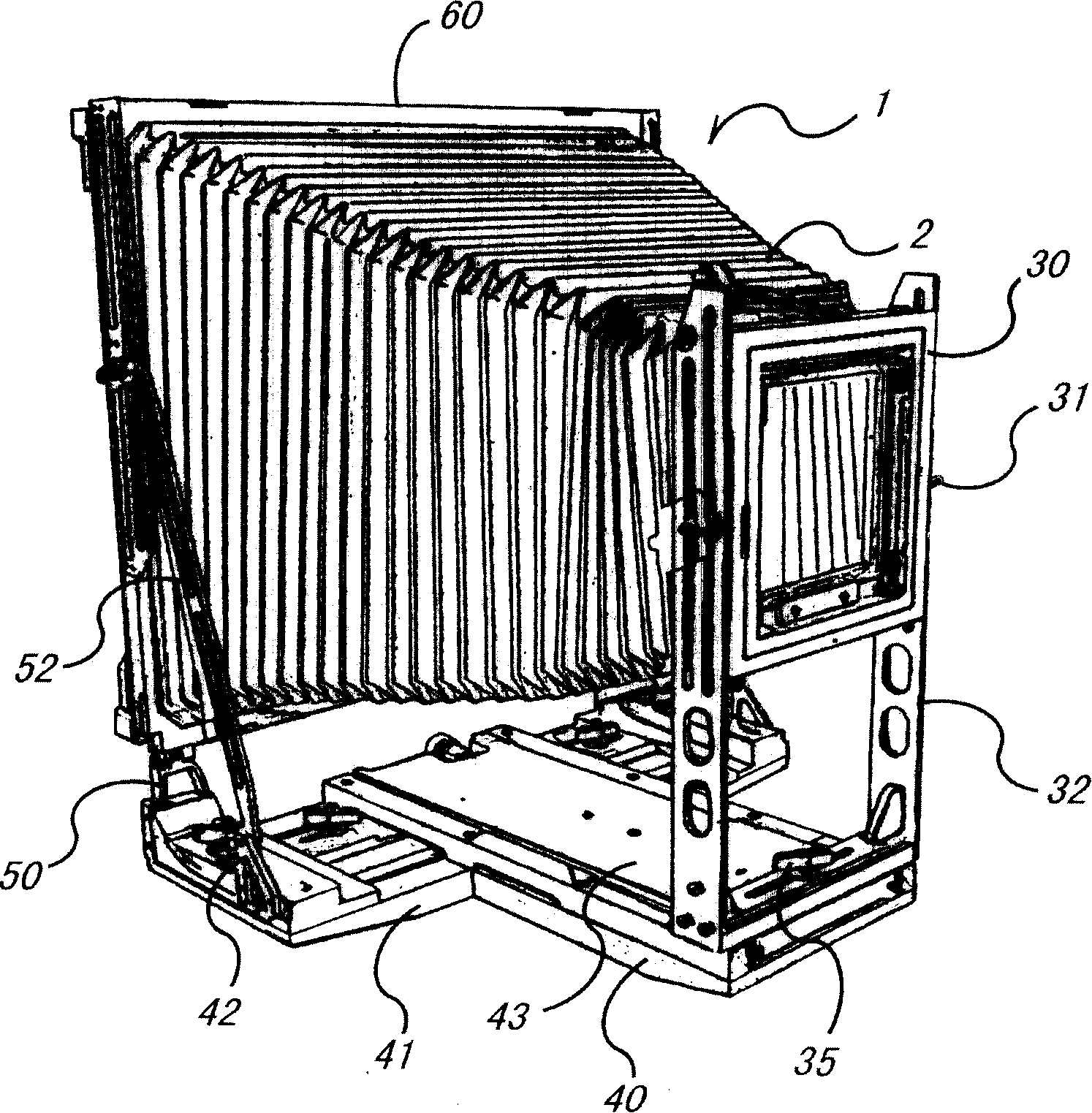

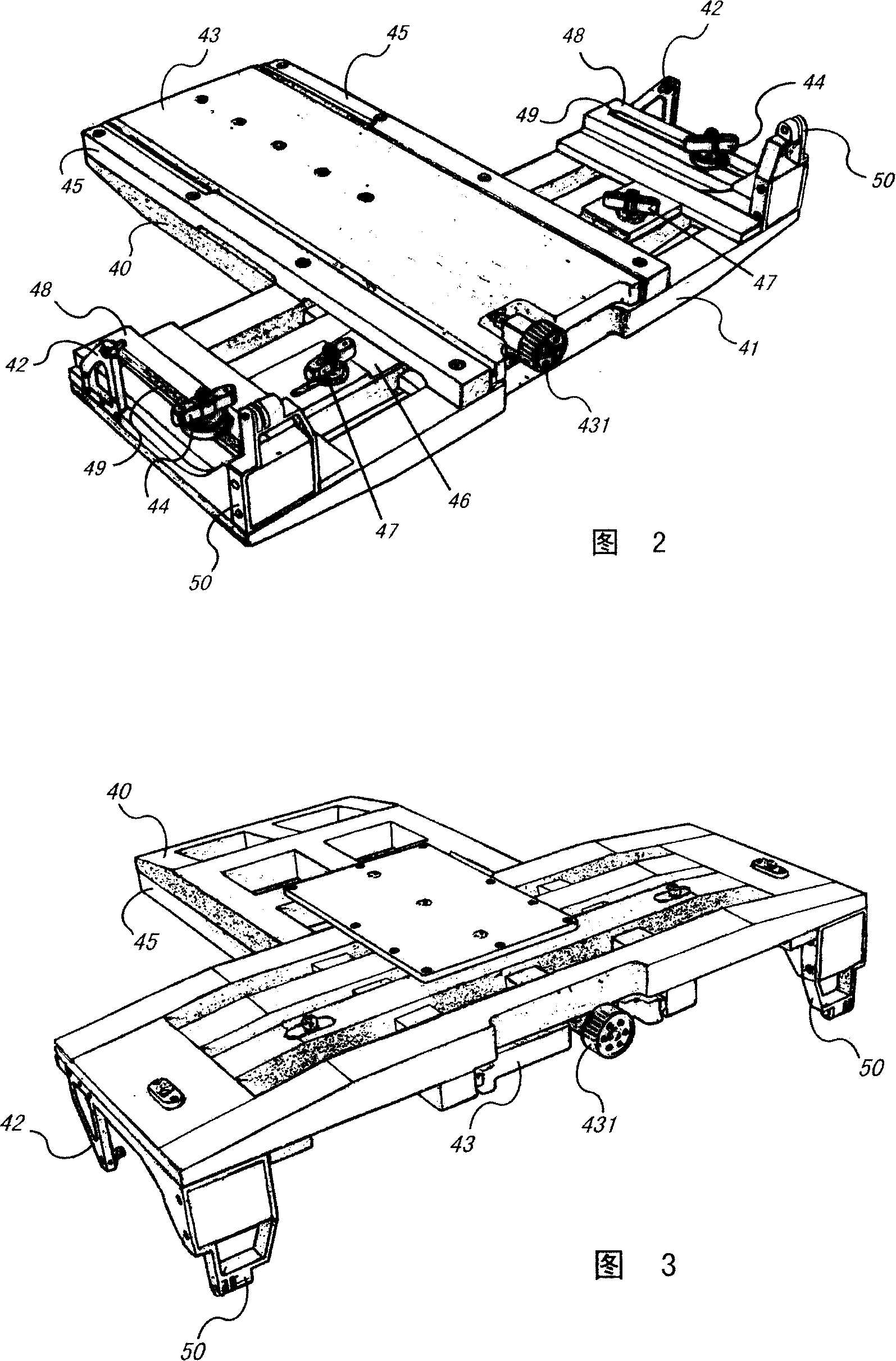

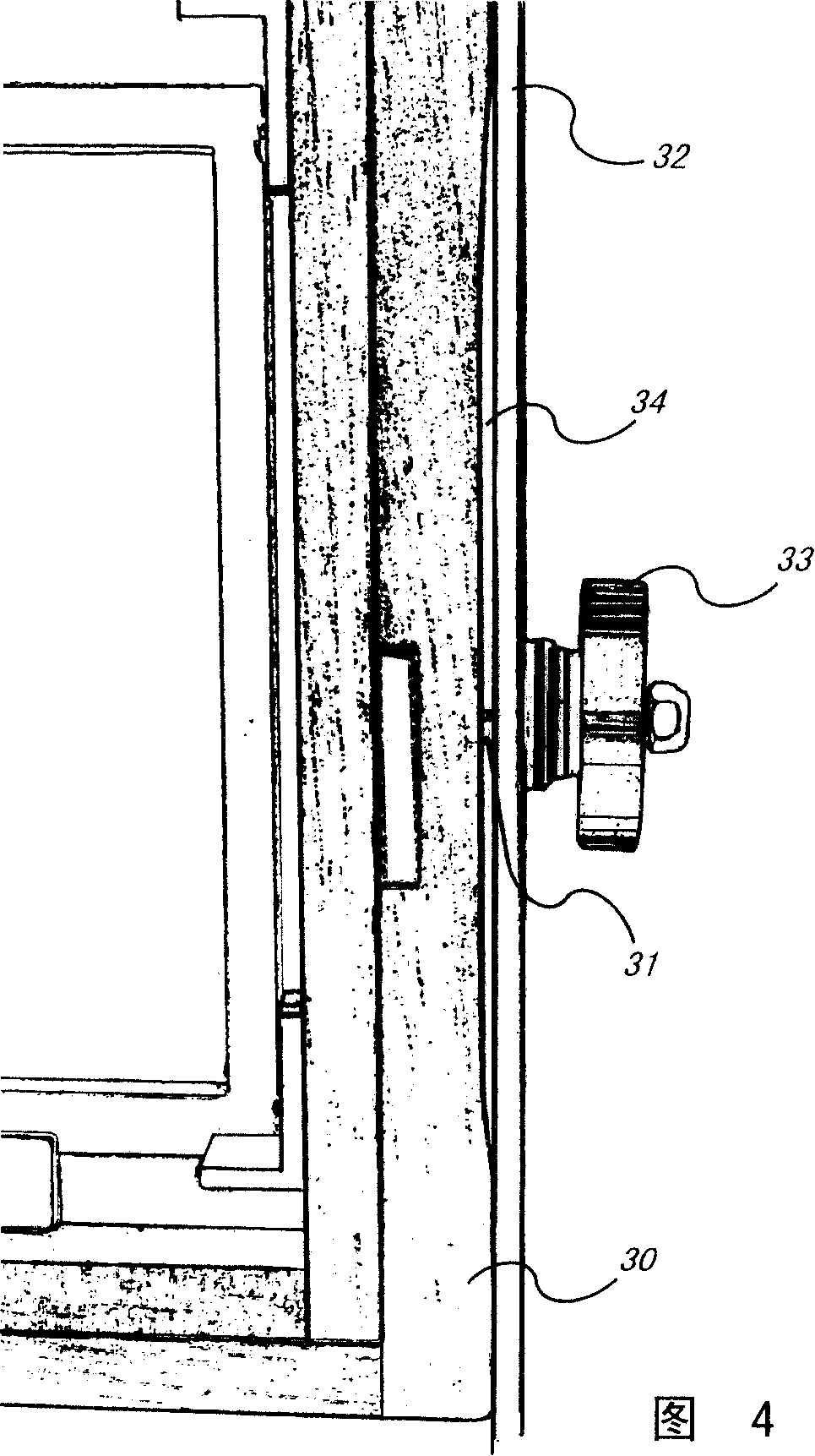

[0015] according to figure 1 To 3, the portable camera landline 1 mainly includes a base, a front group frame 30 , a rear group frame 60 and a bellows 2 . Wherein, the bellows 2 is used to connect the front group frame 30 and the rear group frame 60; the base consists of a base plate 40 and a transverse guide plate 41 to form a “T”-shaped structure, and both sides of the base plate 40 have longitudinal guide rails 45; The longitudinal guide rails 45 can be moved forward and backward together, and can move forward and backward along the longitudinal guide rails 45 through the longitudinal adjustment button 431; the front end of the longitudinal guide plate 43 has a pair of front group arms 32 that can move with the longitudinal guide plate, The group support arm 32 locks the front group support arm 32 on the front end of the longitudinal guide plate 43 through a front group of horizontal locking buttons 35; the front group frame 30 can move up and down and cooperate with the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com