Surface finishing instrument for metal parts and using method thereof

A metal parts and finishing technology, applied in the field of aircraft assembly and manufacturing, can solve problems such as surface scratches, and achieve the effects of good surface quality, precise mechanical structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

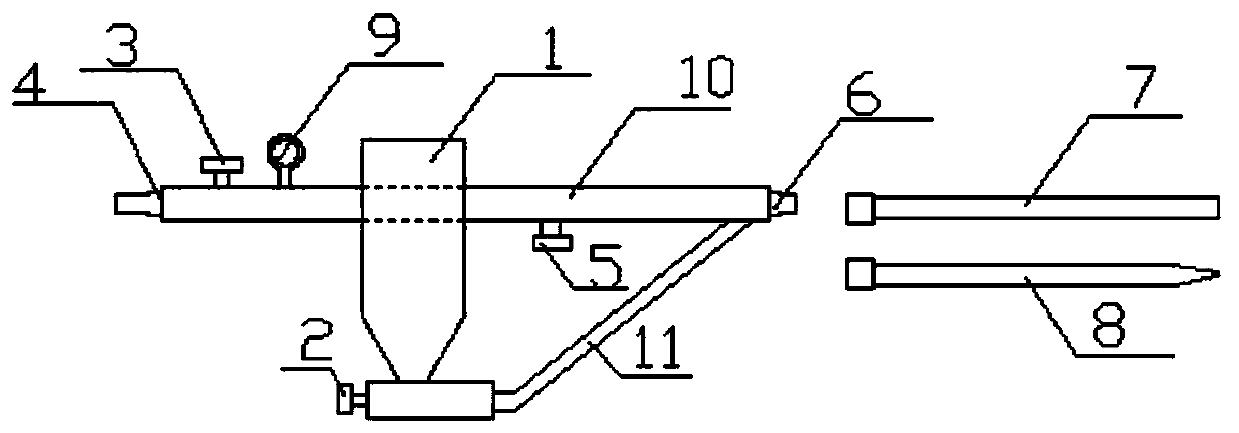

[0022] Such as figure 1 As shown, a metal parts surface finishing instrument includes a finishing material container tank 1, a finishing material flow regulator 2, a compressed air pressure regulator 3, a compressed air pipe joint 4, a compressed air switch 5, a straight-through joint 6, a round Shaped nozzle 7, straight nozzle 8, pressure gauge 9, finishing material and compressed air mixing device 10, finishing material transmission pipe 11;

[0023] The finishing material container 1 is used to store the finishing material; the finishing material container 1 communicates with the mixing device 10 for the finishing material and the compressed air through a transmission pipe 11 for the finishing material, and the finishing material and the The compressed air mixing device 10 is used to mix the compressed air and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com