Heat treated part basket handling robot

A technology for handling robots and baskets, which is applied to conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of low safety, labor and material resources, etc., and achieve high automation, high work efficiency, and precise mechanical structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

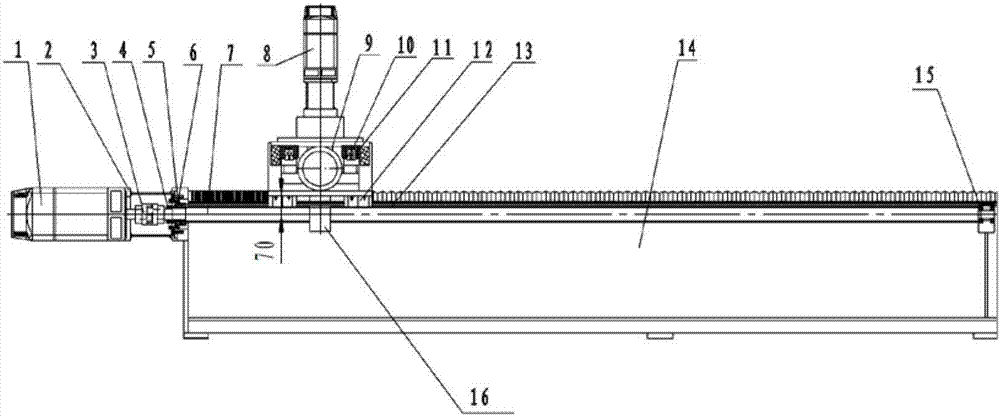

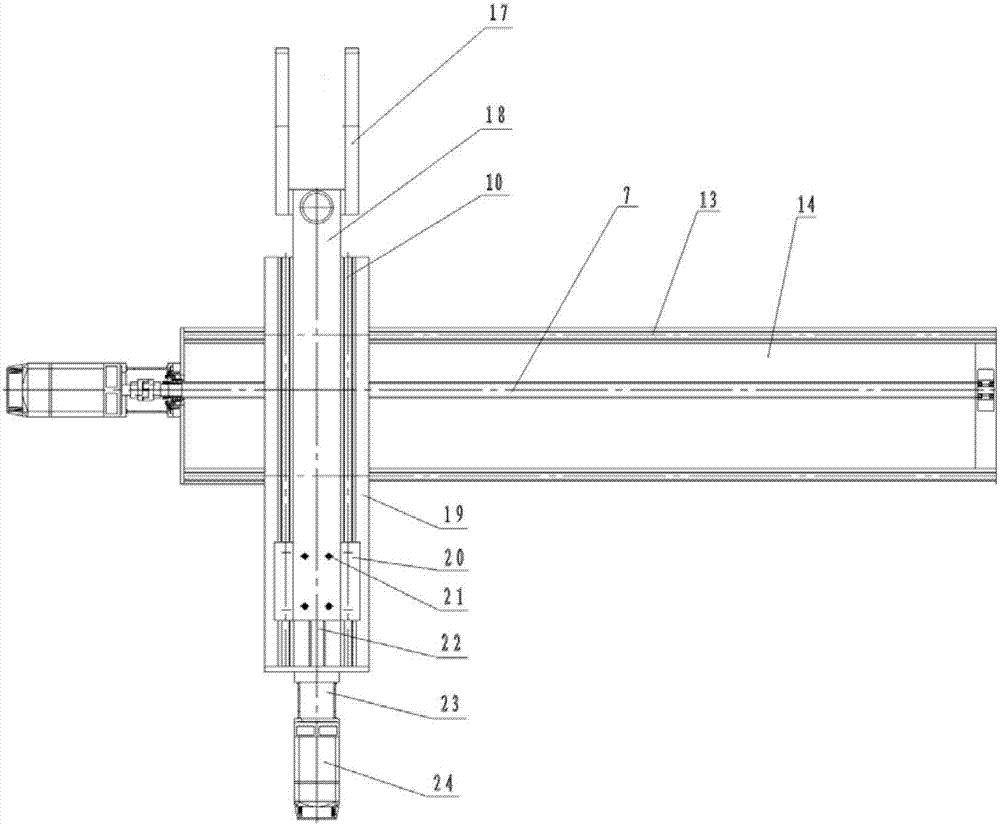

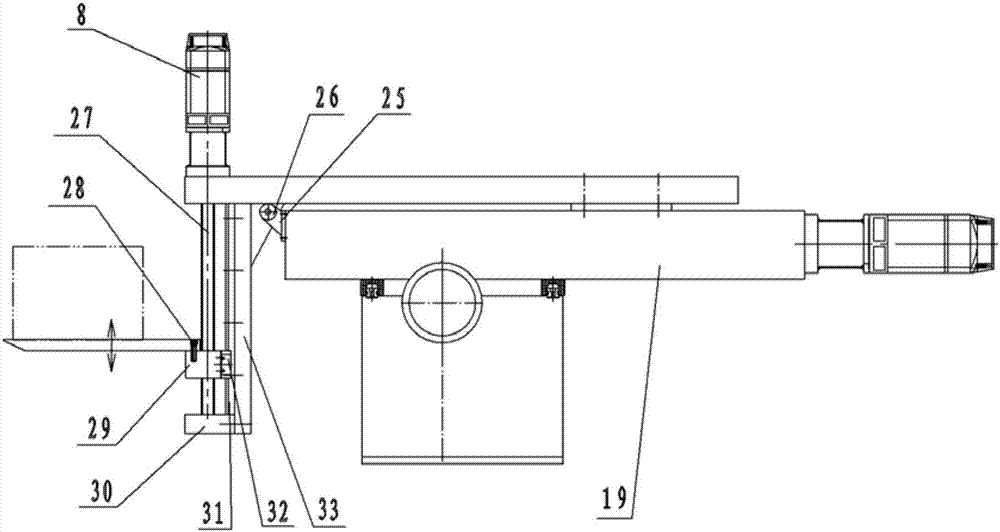

[0027] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a horizontal axis moving system, a vertical axis moving system, a vertical axis moving system and a working fork 17 . The horizontal motor 1 in the horizontal axis moving system rotates, driving all components in the horizontal axis moving system to move along the direction of the horizontal linear guide rail 13 . The vertical motor 24 in the vertical axis moving system rotates to drive all components in the vertical axis moving system to move along the direction of the longitudinal linear guide rail 10 . The vertical motor 8 in the vertical axis moving system rotates, drives each part in the vertical moving system to move along the vertical linear guide rail 31 direction, and then drives the work fork 17 to drag the workpiece material basket to move up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com