SS multilayer mixed flow precipitation device and precipitation method thereof

A settling device and multi-layer mixing technology, which is applied to the feeding/discharging device of the settling tank, sedimentation separation, separation method, etc., can solve the problems of shortening the settling distance of suspended solids, difficult to treat waste water, and collapse of inclined pipe packing. To achieve the effect of ensuring long-term filtering effect, increasing effect and efficiency, and enhancing processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

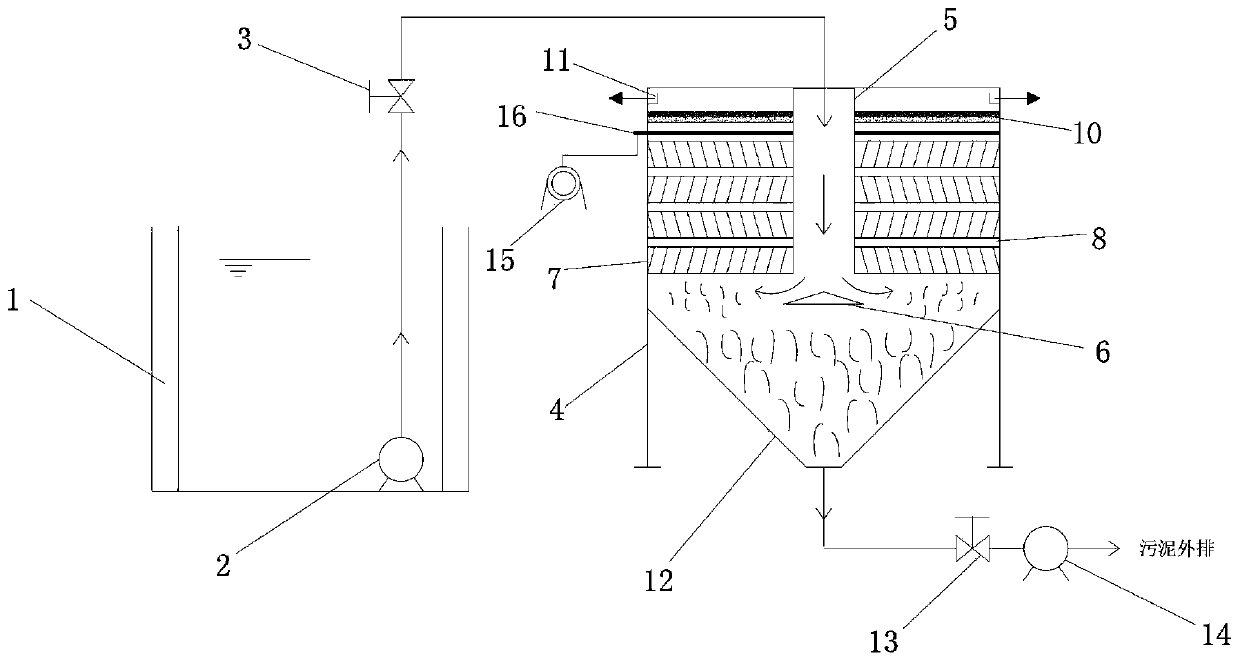

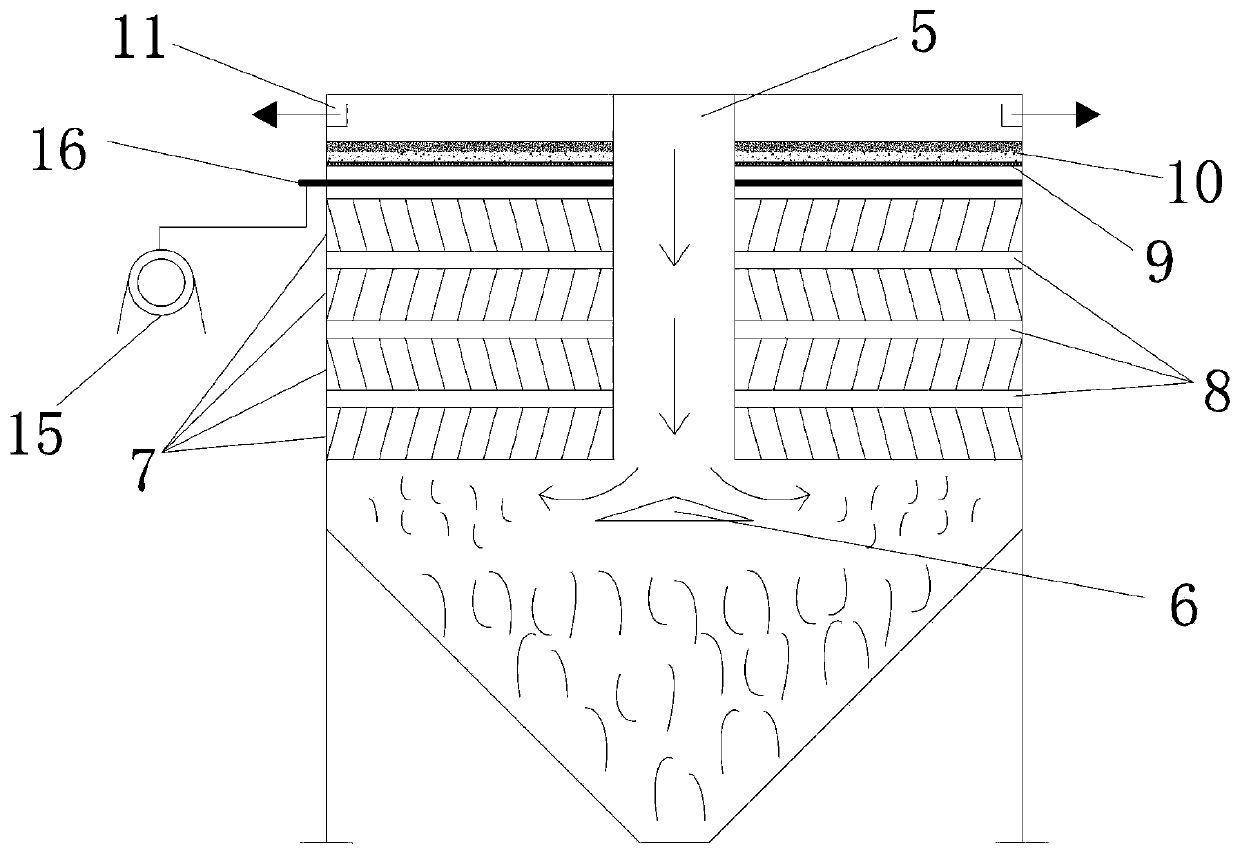

[0024] like figure 1 and 2 As shown, a SS multi-layer mixed flow sedimentation device includes a water inlet module, a high-efficiency sedimentation module and a backwash module. The water inlet module includes a waste water collection tank 1 , a sewage lifting pump 2 and a first on-off valve 3 . The sewage lifting pump 2 is arranged at the bottom of the inner cavity of the waste water collection tank 1 . The water outlet of the sewage lifting pump 2 is connected with the water inlet of the first on-off valve 3 . The high-efficiency sedimentation module includes a sedimentation tank 4, a central water inlet pipe 5, a water retaining weir plate 6, n layers of water purification inclined plates 7, m variable speed mixing areas 8, a fine grid 9, a non-powered sand filter purification area 10, and a second channel Shutoff valve 13 and pneumatic diaphragm pump 14. n≥2, m=n-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com