Probiotic fermented yoghourt and production process thereof

A production process and probiotic technology, applied in the direction of lactobacillus, bifidobacteria, milk preservation, etc., can solve the problems of reducing the nutritional level of yogurt products, reducing the metabolic activity of probiotics, affecting the taste of yogurt, etc., to alleviate lactose intolerance. Symptoms, lowering cholesterol levels, and improving gastrointestinal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

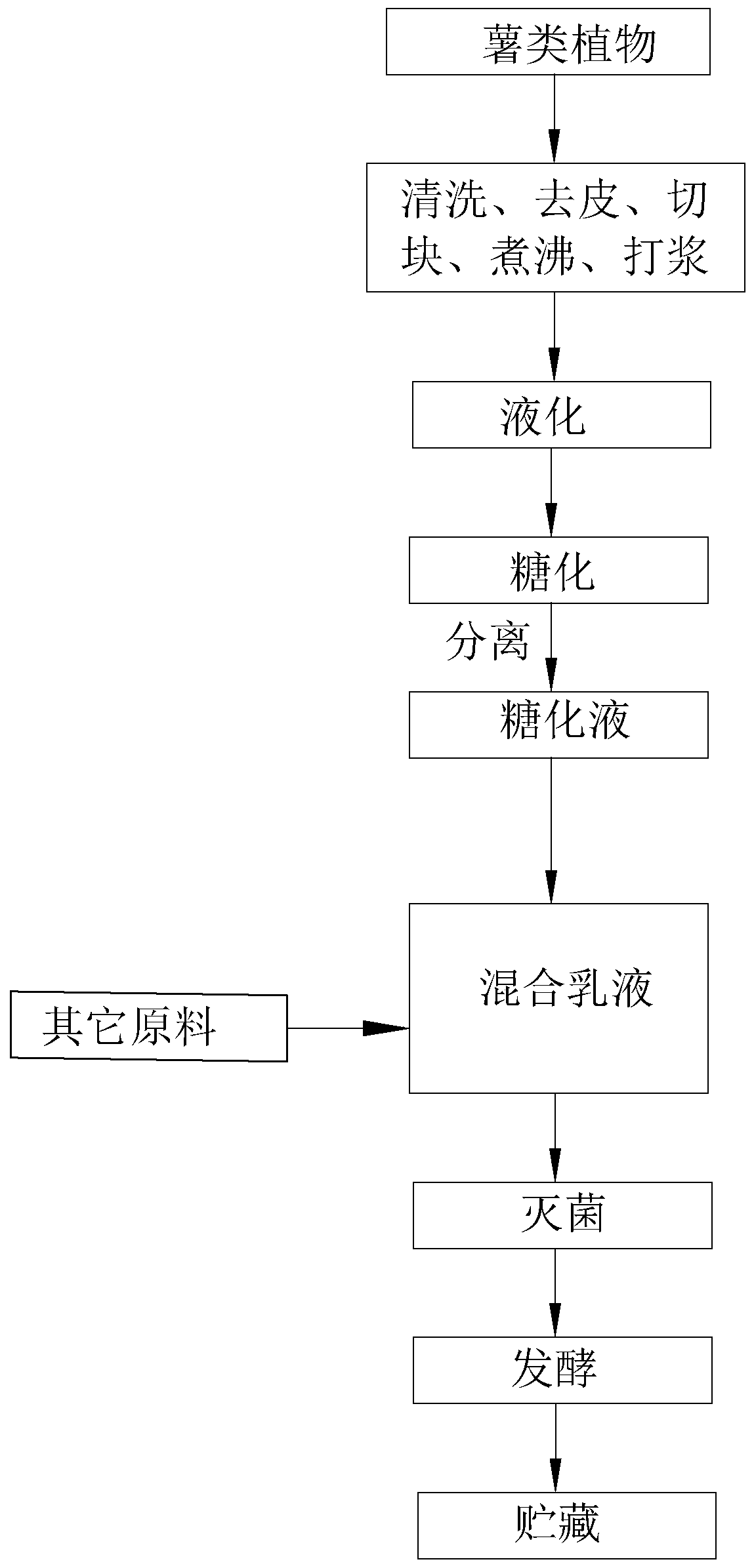

Image

Examples

Embodiment 1

[0036] A probiotic fermented yogurt, comprising the following raw materials: 20kg of skimmed milk powder, 5kg of whey protein powder, 10kg of cassava, 1kg of sucrose, 0.9kg of perilla leaf essential oil, 1.5kg of Lactobacillus bulgaricus, 1.5kg of Streptococcus thermophilus, pectin 0.5kg, 1.2kg of agar, 0.3kg of acetylated distarch phosphate, 0.4kg of diacetyl tartrate mono-diglyceride, and 40kg of purified water.

[0037] A production process of probiotic fermented yoghurt, specifically comprising the steps of:

[0038] Step 1. Clean the cassava, peel it, cut it into pieces, rinse it with running water for 15 minutes, pour it into pure water, boil it for 20 minutes, beat it, add a-high temperature amylase to the slurry for liquefaction, the amount of a-high temperature amylase added is 0.005kg, the liquefaction temperature is 95°C, and the liquefaction time is 60min;

[0039] Step 2. After the liquefaction is completed, add β-amylase to the slurry for saccharification. The a...

Embodiment 2

[0044] A probiotic fermented yogurt, comprising the following raw materials: 25kg of skimmed milk powder, 4kg of whey protein powder, 10kg of potatoes, 1.25kg of sucrose, 0.4kg of clove essential oil, 0.6kg of peppermint essential oil, 1.5kg of Lactobacillus bulgaricus, 1.5 kg of Streptococcus thermophilus kg, Lactobacillus casei 1kg, pectin 0.6kg, agar 1.4kg, acetylated distarch phosphate 0.5kg, diacetyl tartrate mono-diglyceride 0.5kg and purified water 45kg.

[0045] A production process of probiotic fermented yoghurt, specifically comprising the steps of:

[0046] Step 1. Clean the potatoes, peel them, cut them into pieces, rinse them with running water for 30 minutes, then pour them into pure water and boil them for 20 minutes before beating. Add a-high temperature amylase to the slurry for liquefaction. The amount of a-high temperature amylase added It is 0.008kg, the liquefaction temperature is 100℃, and the liquefaction time is 40min;

[0047] Step 2. After the liquef...

Embodiment 3

[0052] A probiotic fermented yogurt, comprising the following raw materials: 30kg of skimmed milk powder, 6.5kg of whey protein powder, 10kg of sweet potato, 1.5kg of sucrose, 0.3kg of cinnamon essential oil, 0.4kg of clove essential oil, 0.7kg of thyme essential oil, and 1.5kg of Lactobacillus bulgaricus , Lactobacillus casei 1kg, Bifidobacterium 1.5kg, pectin 0.8kg, agar 1.6kg, acetylated distarch phosphate 0.7kg, diacetyl tartrate mono-diglyceride 0.6kg and purified water 50kg.

[0053] A production process of probiotic fermented yoghurt, specifically comprising the steps of:

[0054] Step 1. Clean the sweet potatoes, peel them, cut them into pieces, rinse them with running water for 25 minutes, then pour them into pure water and boil them for 25 minutes before beating. Add a-high-temperature amylase to the slurry for liquefaction. The amount of a-high-temperature amylase is 0.01kg, the liquefaction temperature is 98°C, and the liquefaction time is 50min;

[0055] Step 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com