A coil microreactor and a microreactor system

A micro-reactor and micro-channel reactor technology, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve problems such as limited mixing effect and achieve savings The effect of upfront investment, small footprint, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

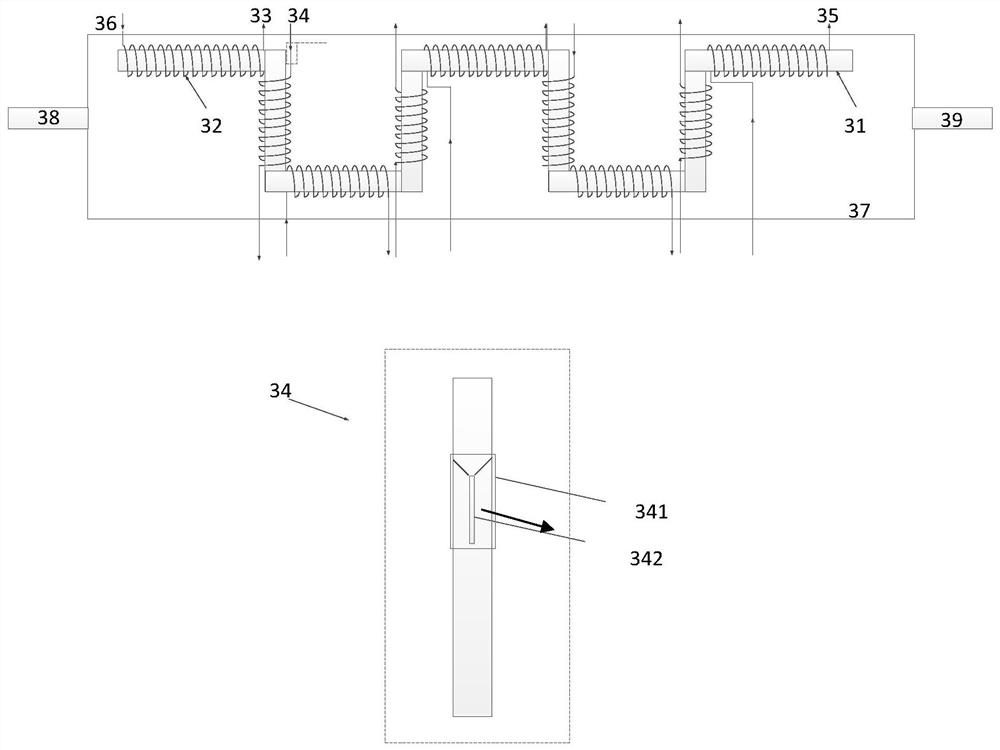

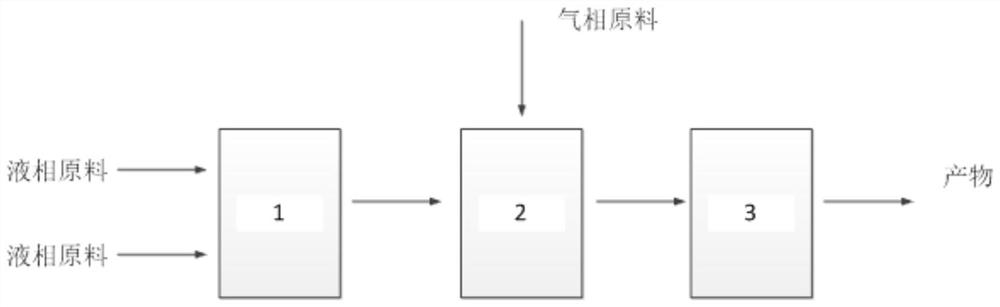

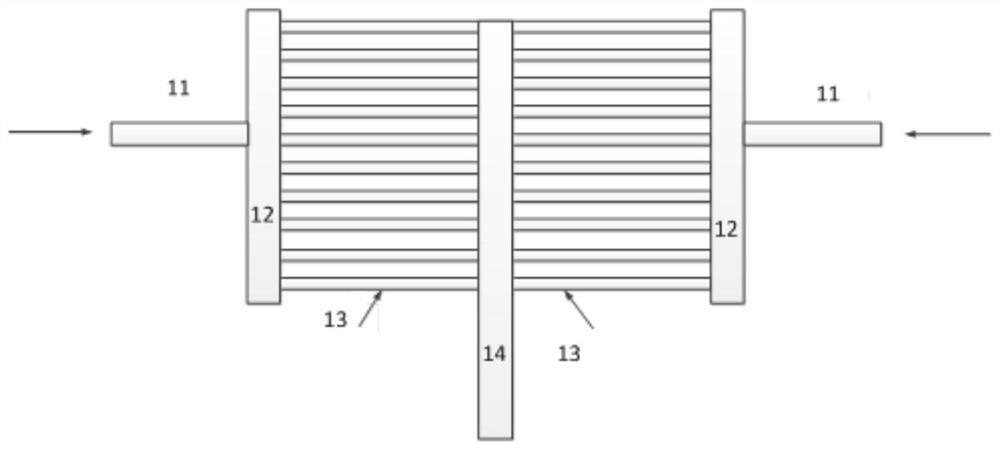

[0135] This embodiment adopts figure 2 The microreactor system shown performs an adsorption desulfurization process for sulfur-containing hydrocarbons, and figure 2 The specific structures of the impinging flow microchannel mixer, two-phase microchannel reactor and coil microreactor involved in image 3 , 4 and shown in 1.

[0136] The process flow in this embodiment is as described in the aforementioned preferred embodiments of the present invention, and other related contents involved are as follows:

[0137] In the impacting flow microchannel mixer 1, the angle between each of the raw material impacting microchannels 13 and the material impacting unit 14 is 90°; the inner diameter of the raw material impacting microchannel 13 is 1mm, and the length is 5mm; The inner diameter of the logistics impact unit 14 is 5mm;

[0138] In the two-phase microchannel reactor 2, the cross-sectional area of the reaction microchannel 25 is 1.5 mm 2 , the distance between two adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com