Lithium-supplementing current collector, preparation method and application thereof, negative pole piece and lithium ion battery

A technology for lithium-ion batteries and negative pole pieces, applied in battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve the problems of reduced compaction density, increased impedance, and more lithiation, so as to prevent lithium precipitation , reduce internal resistance, accelerate the effect of conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The above-mentioned lithium-supplementing current collector can be used in the preparation of lithium-ion batteries, and is especially suitable for negative electrodes in lithium-ion batteries. When the above-mentioned lithium-supplementing current collector is used in the preparation of lithium-ion batteries, the positive and negative electrodes can be prepared first, and then pre-conditioned. Specifically:

[0048] Negative electrode sheet preparation: Negative electrode slurry is obtained by mixing the negative electrode active material, conductive agent, binder and additives uniformly, and the negative electrode slurry is respectively coated on the lithium-replenishing current collector (that is, the porous carbon-coated current collector containing lithium-replenishing material) above, drying at 80-120°C, and rolling after drying to obtain rolled negative electrode sheets. Wherein, the mass ratio of the negative electrode active material, conductive agent, and bin...

Embodiment 1

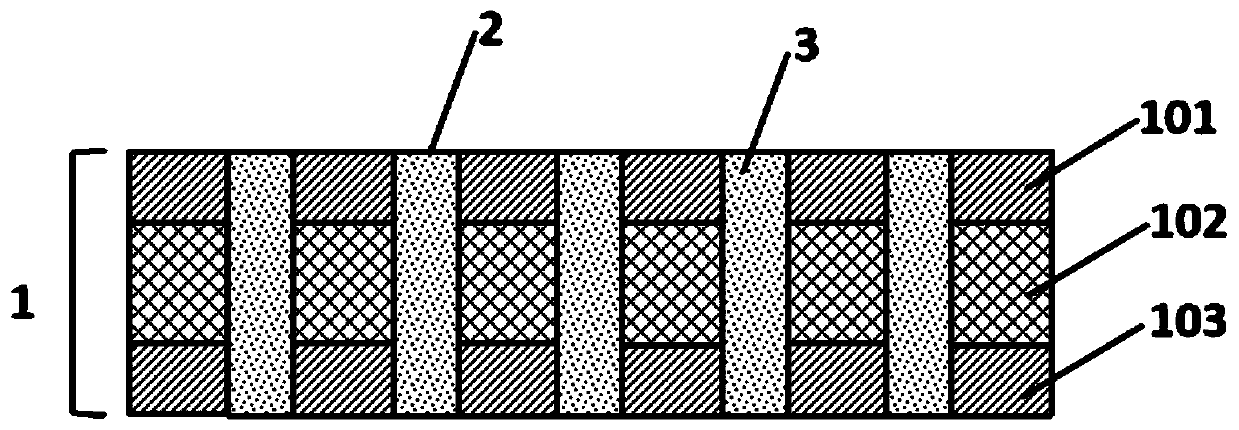

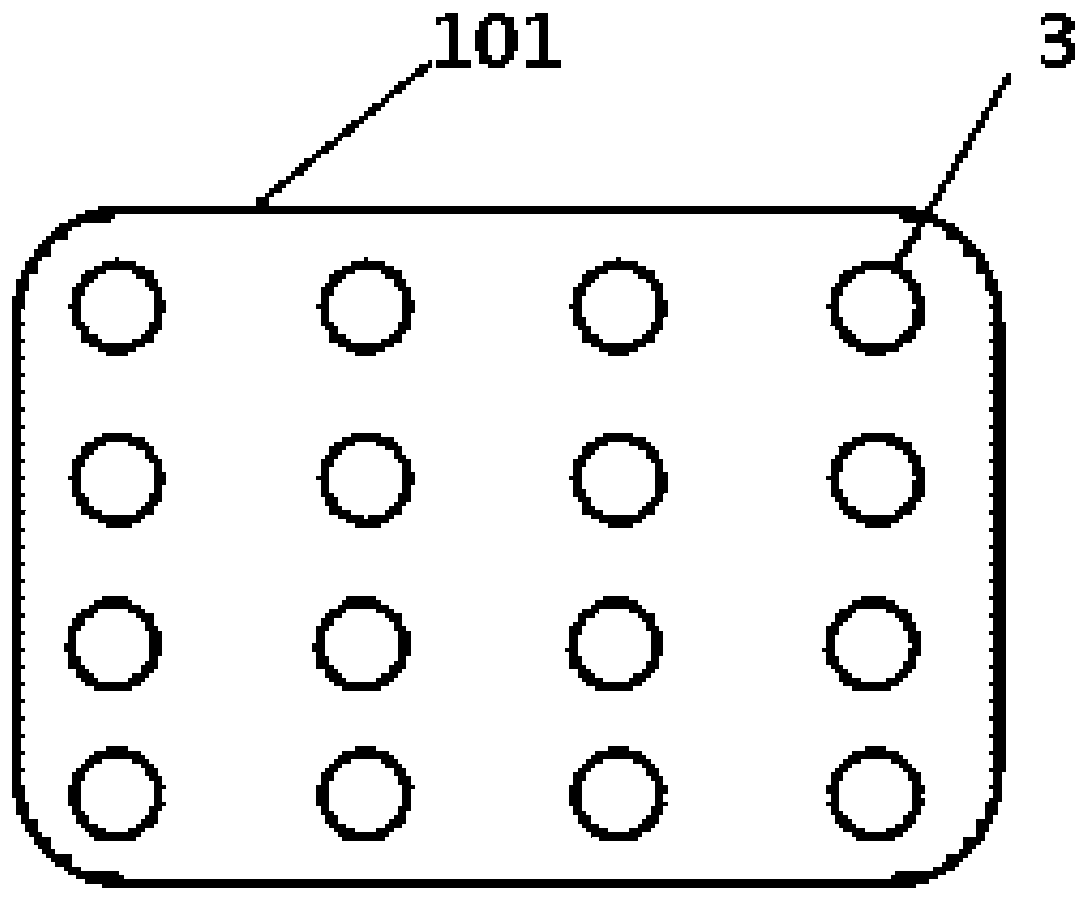

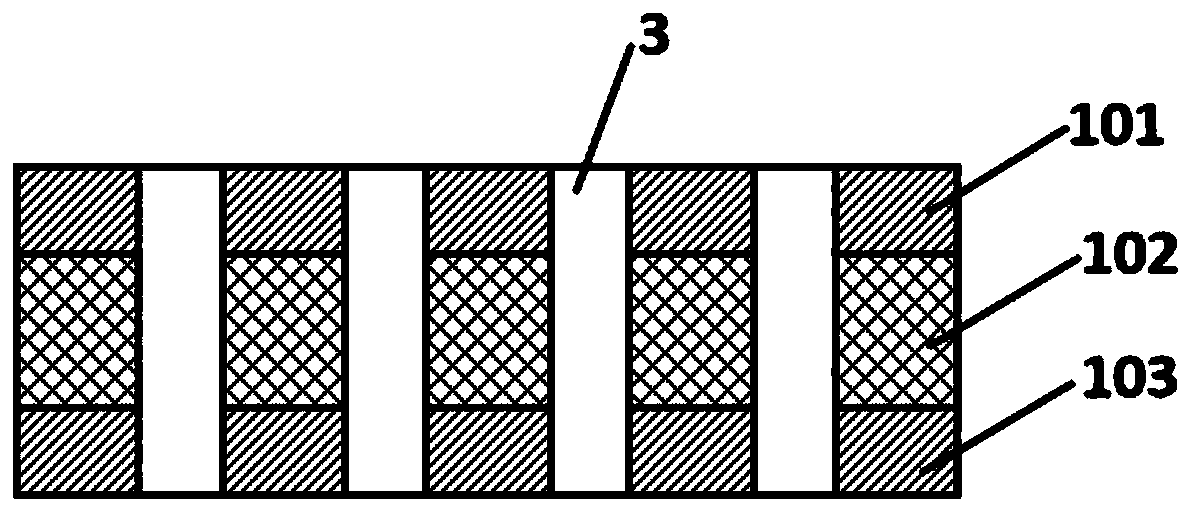

[0053] (1) The body of the current collector is prepared (that is, the preparation of the porous carbon-coated current collector), 90wt% conductive carbon black, 5wt% SBR (styrene-butadiene rubber) and 5wt% CMC (carboxymethyl cellulose sodium) are mixed uniformly (need Illustrate that the consumption of conductive carbon black, SBR and CMC is the mass percent with reference to the total weight of the conductive paste, and the following examples are all the same) to obtain the conductive paste; the prepared conductive paste coating Dry at 90°C on the upper and lower surfaces of the copper foil current collector. After drying, use a punching device to create evenly distributed circular through holes on the carbon-coated copper foil current collector with a porosity of 20%. The schematic diagram of the current collector body is shown in figure 2 and image 3 As shown, the current collector body includes a base layer 102 copper foil with a thickness of 10 μm, a first carbon-coat...

Embodiment 2

[0060] (1) The body of the current collector is prepared (that is, the preparation of the porous carbon-coated current collector). Mix 90wt% conductive carbon black, 5wt% SBR (styrene-butadiene rubber) and 5wt% CMC (carboxymethyl cellulose sodium) to conduct electricity Slurry: Coat the prepared conductive paste on the upper and lower surfaces of the copper foil current collector, and dry it at 90°C. After drying, use a punching device to create evenly distributed Circular through hole with 20% porosity. The current collector body includes a base layer copper foil with a thickness of 10 μm, a first carbon-coated layer and a second carbon-coated layer respectively located on the upper surface and the lower surface of the base layer, both with a thickness of 3 μm, and located on the current collector body (also That is, the through holes on the carbon-coated current collector), the diameter of the through holes is 0.2 μm.

[0061] (2) Negative active material (a mixture of grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com