Method for preparing lithium-supplementing negative electrode and lithium-supplementing negative electrode

A technology of negative electrode sheet and negative electrode, which is applied in the field of preparation process of lithium-supplemented negative electrode, can solve problems such as potential safety hazards and lithium dendrite formation, and achieve good peeling effect, simple process, and convenient peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Negative electrode preparation: use artificial graphite as the negative electrode active material, acetylene black as the conductive agent, and polyvinylidene fluoride (PVDF) as the binder. The above materials are mixed at a weight ratio of graphite: acetylene black: PVDF = 90:5:5, and a certain amount of ultrapure water is added to mix evenly to obtain a mixed slurry. The mixed slurry was coated on both sides of a copper foil (about 6 μm in thickness), dried and compacted to obtain a graphite negative electrode (with a thickness of 160 μm).

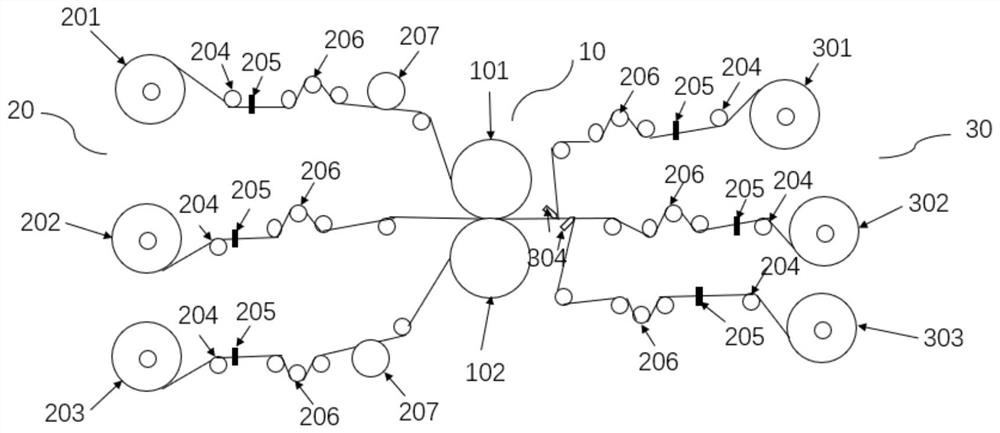

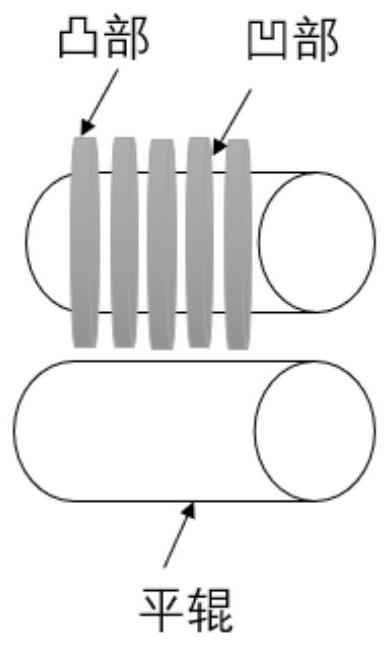

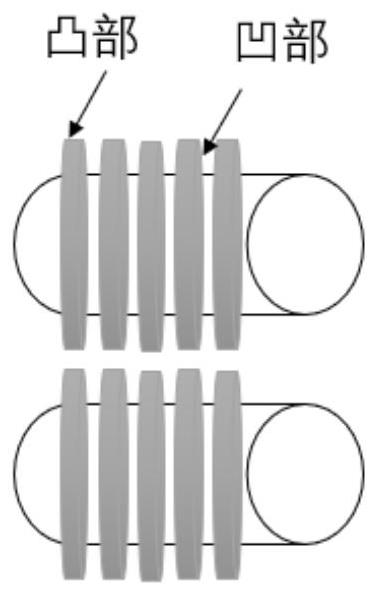

[0041]Lithium-supplementing negative electrode 1 Preparation: In a dry workshop with a dew point of -45°C, use an ultra-thin lithium film with a thickness of 5 μm as the lithium-supplementing source, use the above-mentioned negative electrode as the negative electrode to be replenished, and use the upper and lower volumes of lithium and the negative electrode with the help of concave-convex Roller and flat roller (the width of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com