High-filling-capacity hexagonal boron nitride nanosheet/fiber/polymer blocky composite material and preparation method thereof

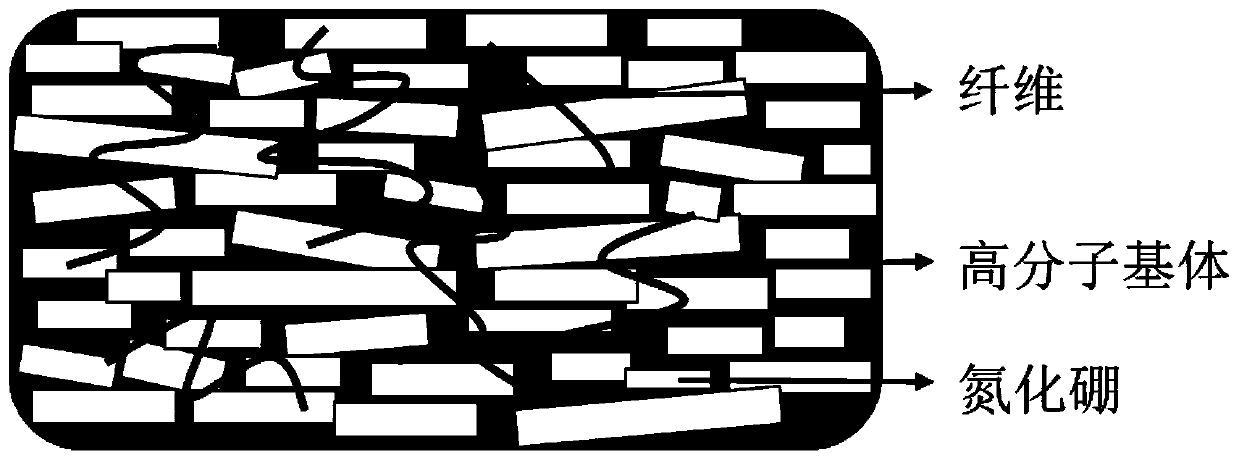

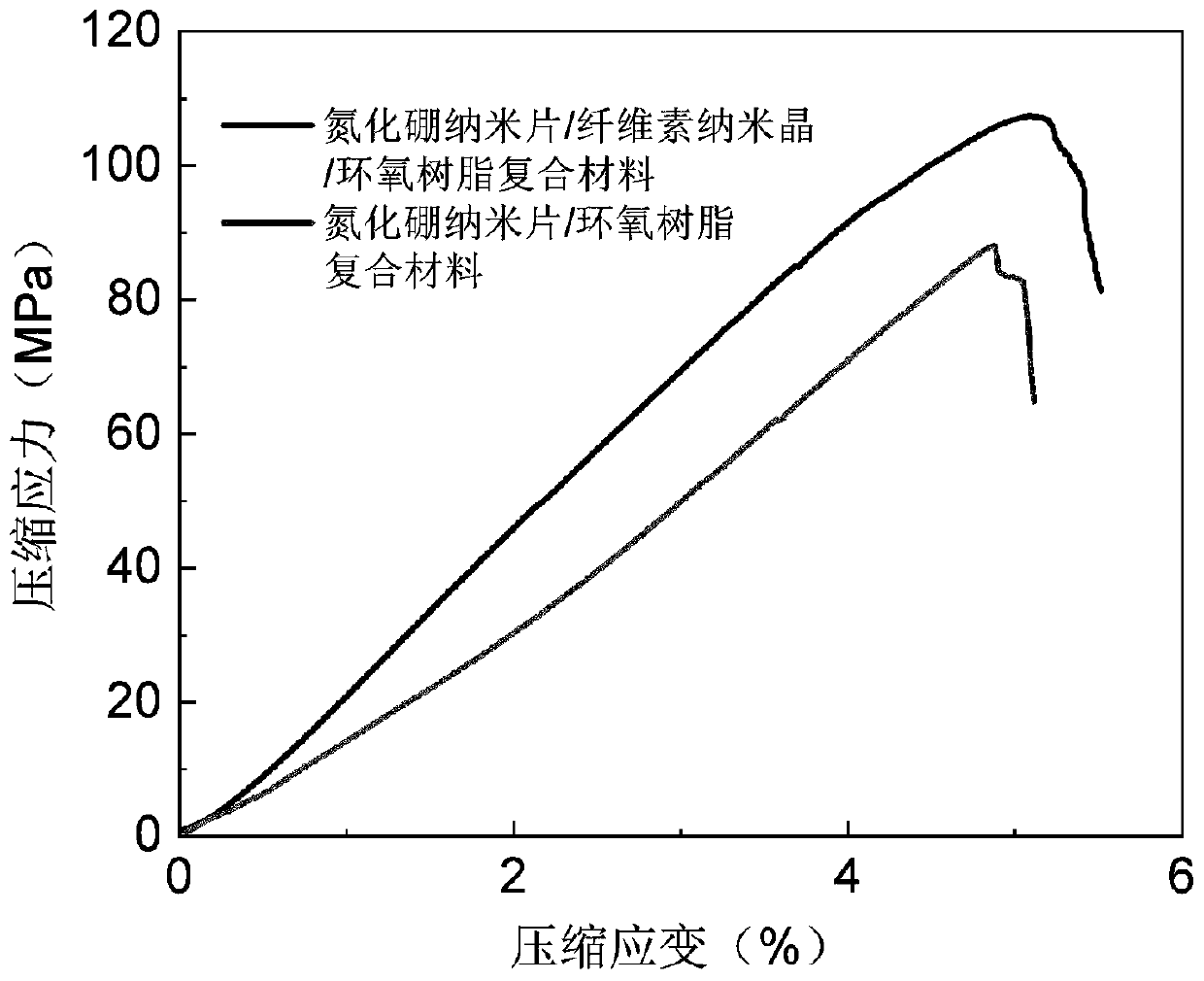

A technology of hexagonal boron nitride and composite materials, which is applied in the field of preparation of high-filling hexagonal boron nitride nanosheet/fiber/polymer block composite materials, which can solve the problems of low thermal conductivity, deterioration of mechanical properties and processing performance of composite materials, etc. problems, to achieve high mechanical strength, facilitate large-scale implementation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1: Disperse 5 g of hexagonal boron nitride nanosheets into 0.5 L of water. At this time, the dispersion solvent is water, the concentration of the boron nitride solution is 10 g / L, and ultrasonic treatment is performed for 3 hours to obtain a dispersion of hexagonal boron nitride nanosheets; Add 100mL of cellulose nanocrystal solution with a concentration of 10g / L to the dispersion of hexagonal boron nitride nanosheets, stir for 24h, place the resulting mixture in a -50°C ultra-low temperature freezer for 2h, and then Freeze-dry in a freeze dryer for 48 hours at a temperature of -50°C and a pressure of 30Pa to obtain a boron nitride nanosheet / cellulose nanocrystal hybrid filler;

[0043] Step 2: 15g boron nitride nanosheet / cellulose nanocrystalline hybrid filler, 4.32g bisphenol A epoxy resin, 3.67g methyltetrahydrophthalic anhydride (curing agent) and 0.08g2,4,6-tri( Dimethylaminomethyl) phenol (catalyst) is added in the agate artificial mortar, grinds and mixes e...

Embodiment 2

[0049] Step 1: Disperse 7.5g of hexagonal boron nitride nanosheets into 0.5L of water solvent, the concentration of boron nitride solution is 15g / L, ultrasonic treatment for 3h, to obtain hexagonal boron nitride nanosheet dispersion; Add 100mL of microcrystalline cellulose solution with a concentration of 15g / L to the boron nanosheet dispersion, stir for 48h, place the resulting mixture in a -50°C ultra-low temperature refrigerator for 2h, and then place it in a freeze-dry Freeze-drying in the machine for 48 hours at a temperature of -50°C and a pressure of 30Pa to obtain hexagonal boron nitride nanosheet / microcrystalline cellulose hybrid filler;

[0050] Step 2: Mix 15g of hexagonal boron nitride nanosheet / microcrystalline cellulose hybrid filler, 4.32g of bisphenol A epoxy resin, 3.67g of methyltetrahydrophthalic anhydride (curing agent) and 0.08g of 2,4,6-tris (Dimethylaminomethyl) phenol (catalyst) joins in the agate artificial mortar, grinds and mixes evenly to obtain the...

Embodiment 3

[0055] Step 1: Place 500mL of microcrystalline cellulose solution with a concentration of 5g / L in an ultra-low temperature refrigerator at -50°C for 2 hours, and then place it in a freeze dryer for 48 hours to freeze-dry at -50°C , the pressure is 30Pa to obtain microcrystalline cellulose, which is then placed in a mortar and ground into powder;

[0056] Step 2: 2.5g microcrystalline cellulose powder in step 1, 15g boron nitride nanosheet filler, 4.32g bisphenol A epoxy resin, 3.67g methyltetrahydrophthalic anhydride (curing agent) and 0.08g2,4 , 6-tris(dimethylaminomethyl)phenol (catalyst) was added in an agate artificial mortar, ground and mixed uniformly to obtain hexagonal boron nitride nanosheet / microcrystalline cellulose-epoxy resin mixture;

[0057] Step 3: Put the mixture of hexagonal boron nitride nanosheets / microcrystalline cellulose-epoxy resin in step 2 into a polytetrafluoroethylene ball mill jar, and mix evenly in a planetary ball mill, wherein the speed of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compression modulus | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com