Advanced wastewater treatment method and system capable of realizing sludge source reduction

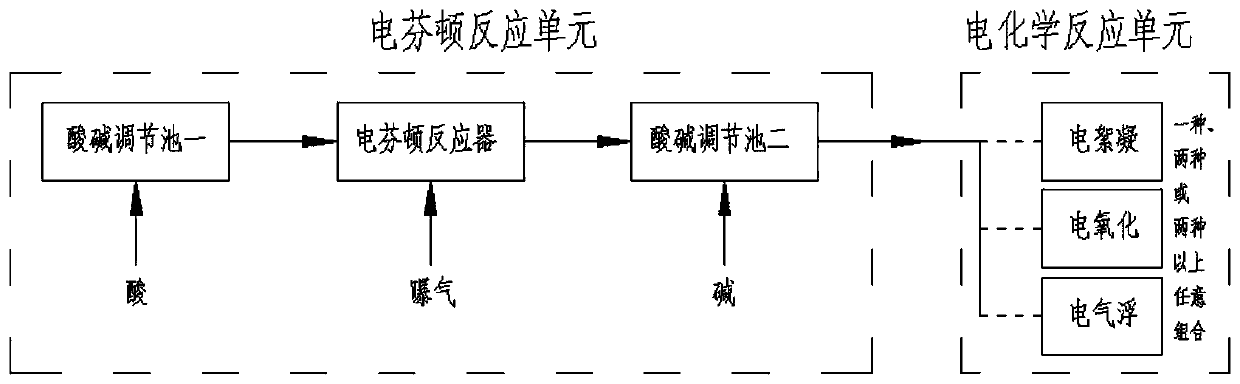

It is an advanced treatment and reduction technology, which is applied in water/sludge/sewage treatment, water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problems of low efficiency, electro-Fenton and electrochemical treatment. Thoroughness, large sludge output and other problems, to achieve the effect of convenient operation, wide application range, and reduced sludge output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The main pollutants of the wastewater are COD, suspended solids and total phosphorus. In this embodiment, the electro-Fenton combined electrocoagulation process is adopted. The wastewater enters the electro-Fenton reaction unit, first enters the first acid-base adjustment pool, and adds sulfuric acid solution to adjust the pH value. To 3, enter the electric Fenton reactor for Fenton deep oxidation, the aeration device aerates the cathode, the anode uses an iron plate, the cathode uses an activated carbon fiber plate, the reaction time of the electric Fenton reaction unit is 50min, and the voltage is controlled at 4V. The current control is 100mA, and the aeration rate is 1.5m 3 / h, after the electro-Fenton reaction is completed, the effluent enters the second acid-base adjustment tank, and the sodium hydroxide solution is added to adjust the pH value to 7, and then enters the electroflocculation reaction unit. The anode is made of aluminum plate, and the cathode is made ...

Embodiment 2

[0071] The main pollutants of the wastewater are COD, suspended solids and total phosphorus, and the COD content is relatively high. This embodiment adopts the electro-Fenton combined electro-oxidation + electro-flocculation process, and the wastewater enters the electro-Fenton reaction unit, and first enters the first acid-base adjustment pool , add sulfuric acid solution, adjust the pH value to 3, and then enter the electric Fenton reactor for Fenton deep oxidation, the aeration device aerates the cathode, the anode uses an iron plate, the cathode uses an activated carbon fiber plate, and the reaction time of the electric Fenton reaction unit 50min, the voltage is controlled at 4V, the current is controlled at 120mA, and the aeration volume is controlled at 1.8m 3 / h, after the electro-Fenton reaction is completed, the effluent enters the second acid-base adjustment tank, and the sodium hydroxide solution is added to adjust the pH value to 7, and then enters the electro-oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com