Preparation method of particle size controllable type copper-tin prealloy powder with ultrahigh tin content

A pre-alloyed powder and content technology, which is applied in the field of preparation of copper-tin pre-alloyed powder, can solve the problems of copper-tin alloy tin content, uneven distribution, uncontrollable particle size of alloy powder, etc. Grain growth is conducive to the effect of rapid nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

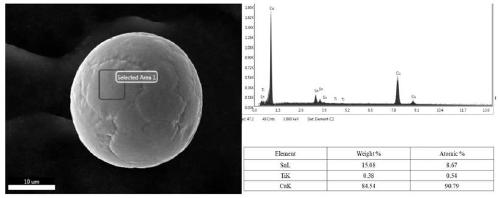

Embodiment 1

[0033] Preliminary preparation of raw materials: Weigh 83.0% of Cu powder, 16.6% of Sn powder, and 0.4% of Ti powder, put them into a ball mill jar, and use a planetary ball mill to mix the powder at a speed of 100r / min for 4 hours. The reversal time is 10 minutes, the ball-to-material ratio is 1:2, and then the mixed powder is put into a pressing mold, and a cold pressing machine is used to make a cold compact.

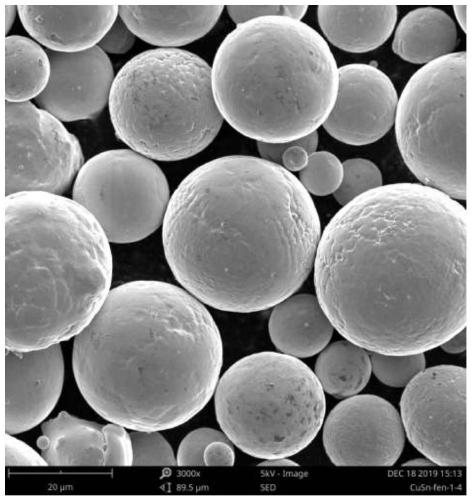

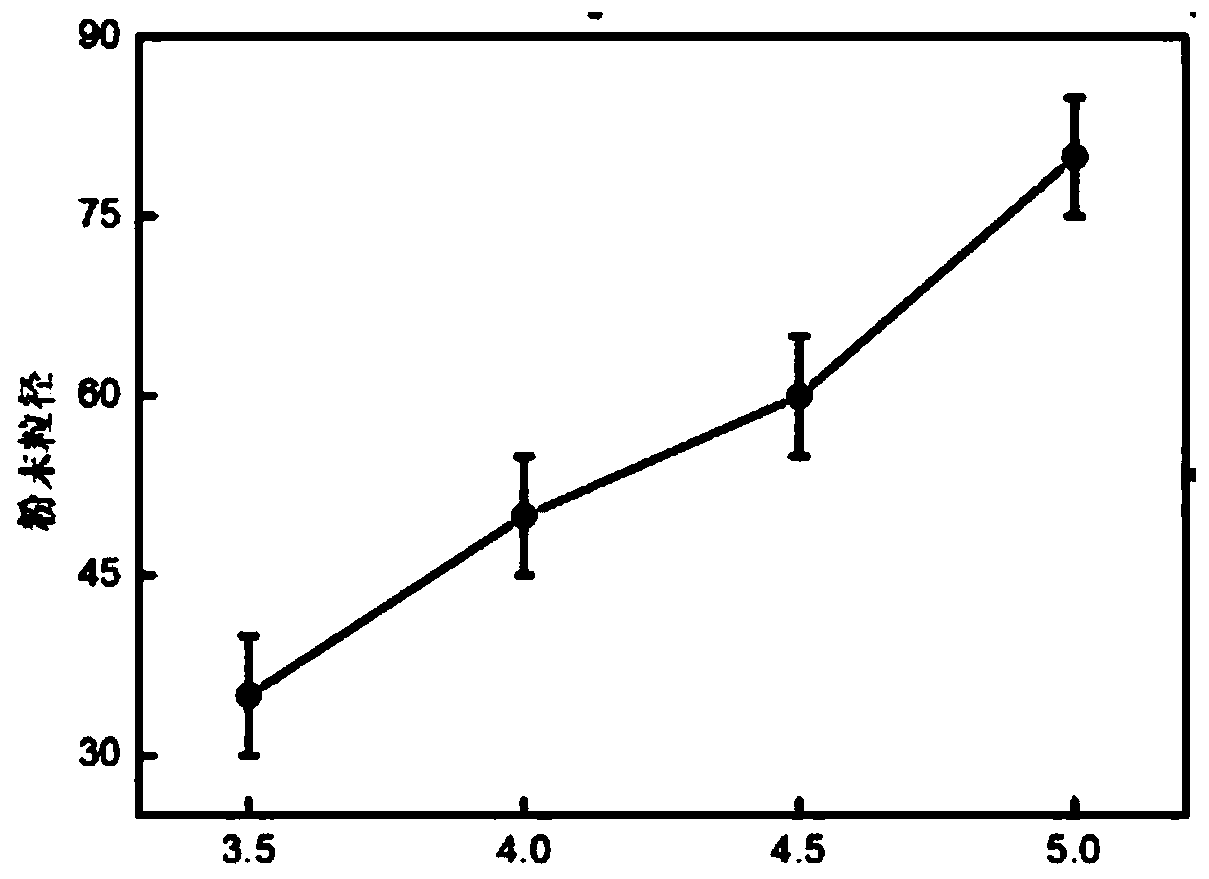

[0034] Cover the inner wall and bottom of the graphite crucible with graphite paper, and cut a small hole at the bottom with the same diameter as the upper end of the nozzle to ensure that the nozzle can be placed in the bottom of the graphite crucible. The diameter of the nozzle is 3.5 μm. Then put the cold compact into the crucible, reserve a space for the corundum tube to be lifted and lowered, and ensure that the corundum tube can fit closely with the upper end of the nozzle after being inserted into the crucible. Then place the crucible inside the furnace door, ...

Embodiment 2

[0039]Preliminary preparation of raw materials: Weigh 80.0% of Cu powder, 19.6% of Sn powder, and 0.4% of Ti powder, and then put them into a ball mill tank, and use a planetary ball mill to mix the powder, the powder mixing speed is 200r / min, and the powder mixing time is 4h , forward and reverse time 10min, ball to material ratio 1:2. Then put the mixed powder into the pressing mold, and use a cold press to make a cold compact.

[0040] Cover the inner wall and bottom of the graphite crucible with graphite paper, and cut a small hole at the bottom with the same diameter as the upper end of the nozzle to ensure that the nozzle can be placed in the bottom of the graphite crucible, and the diameter of the nozzle is 5.0 μm. Then put the cold compact into the crucible, reserve a space for the corundum tube to be lifted and lowered, and ensure that the corundum tube can fit closely with the upper end of the nozzle after being inserted into the crucible. Then place the crucible in...

Embodiment 3

[0044] Preliminary preparation of raw materials: Weigh 79.6% of Cu powder, 20.0% of Sn powder, and 0.4% of Ti powder, and then put them into a ball mill tank, and use a planetary ball mill to mix the powder, the powder mixing speed is 100r / min, and the powder mixing time is 4h , forward and reverse time 10min, ball to material ratio 1:2. Then put the mixed powder into the pressing mold, and use a cold press to make a cold compact.

[0045] Cover the inner wall and bottom of the graphite crucible with graphite paper, and cut a small hole at the bottom with the same diameter as the upper end of the nozzle to ensure that the nozzle can be placed in the bottom of the graphite crucible. The diameter of the nozzle is 4.5 μm. Then put the cold compact into the crucible, reserve a space for the corundum tube to be lifted and lowered, and ensure that the corundum tube can fit closely with the upper end of the nozzle after being inserted into the crucible. Then place the crucible insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com