Three-stage energy absorption support design method for coal mine rock burst roadway

A technology of rock burst and design methods, applied in mining equipment, seismology, earthwork drilling and mining, etc., can solve the problems of cumbersome operation, unconsidered, inaccurate kinetic energy, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A certain mine is a rock burst mine, the geological structure of the mine is simple, and the coal seam has the risk of impact. The coal seam recovery roadway has a span of 5m and a height of 3.5m. When the most serious rock burst occurred in this mine, the microseismic energy monitored by the microseismic monitoring system was 1.3×10 6 J, the distance between the maximum microseismic source and the damage point of the roadway is 40m, and the surface displacement of the roadway caused by rock burst is R=0.4m.

[0034] After the impact occurs in the mine, the anti-scour energy-absorbing support is used as one of the measures for rock burst control.

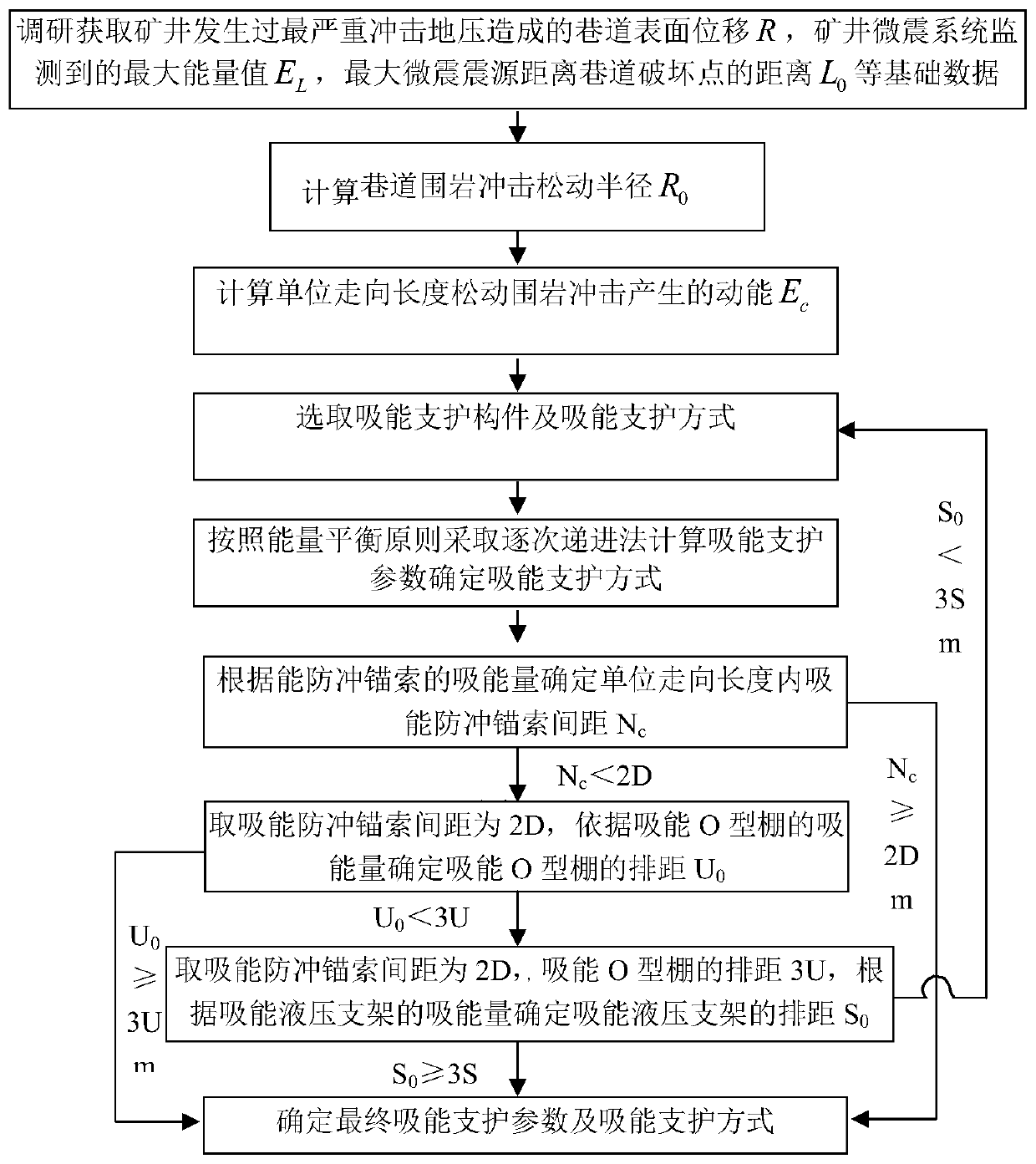

[0035] to combine figure 1 , the specific steps of the anti-scour energy-absorbing support design in this embodiment are as follows:

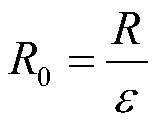

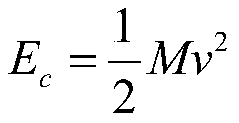

[0036] (1) According to the survey, the most serious rock burst occurred in the mine caused the surface displacement of the roadway R = 0.4m, and the maximum energy value E detected by the m...

Embodiment 2

[0046] A mine is a rock burst mine with a simple geological structure. The coal seam mining roadway has a span of 5m and a height of 3.5m. When the most serious rock burst occurred in this mine, the microseismic energy monitored by the microseismic monitoring system was 2.7×10 6 J, the distance between the maximum microseismic source and the damage point of the roadway is 45m, and the surface displacement of the roadway caused by rock burst is R=0.5m.

[0047] After the impact occurs in the mine, the anti-scour energy-absorbing support is used as one of the measures for rock burst control.

[0048] to combine figure 1 , the specific steps of the anti-scour energy-absorbing support design in this embodiment are as follows:

[0049] (1) According to the survey, the most serious rock burst occurred in the mine caused the surface displacement of the roadway R = 0.5m, and the maximum energy value E detected by the mine microseismic system L =2.7×10 6 J, the distance L between t...

Embodiment 3

[0059]A mine is a rock burst mine with a simple geological structure and relatively hard coal seam with a hard roof. The coal seam mining roadway has a span of 5m and a height of 3.5m. When the most serious rock burst occurred in this mine, the microseismic energy monitored by the microseismic monitoring system was 1.0×10 7 J, the distance between the maximum microseismic source and the damage point of the roadway is 55m, and the surface displacement of the roadway caused by rock burst is R=0.5m.

[0060] After the impact occurs in the mine, the anti-scour energy-absorbing support is used as one of the measures for rock burst control.

[0061] combine figure 1 , the specific steps of the anti-scour energy-absorbing support design in this embodiment are as follows:

[0062] (1) According to the survey, the most serious rock burst occurred in the mine caused the surface displacement of the roadway R = 0.5m, and the maximum energy value E detected by the mine microseismic syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com