Single-cylinder engine bench experiment system with reverse towing function, and control method of single-cylinder engine bench experiment system

An engine bench and experimental system technology, applied in the direction of internal combustion engine testing, etc., can solve problems such as high requirements and few experimental studies, and achieve the effects of reduced requirements, rapid response, and accurate calculation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

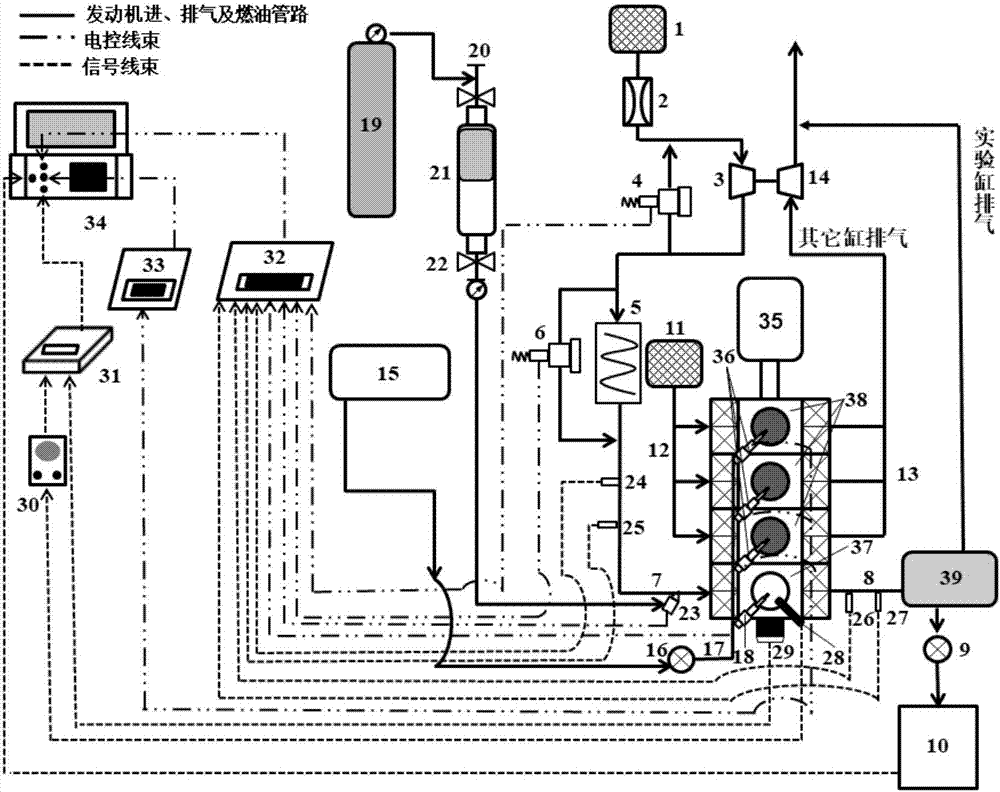

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing, and the explanation of each label in the figure is: 1-the first air filter, 2-intake flow meter, 3-exhaust gas turbocharger compressor, 4- Supercharger bypass valve, 5-intake intercooler, 6-intercooler bypass valve, 7-intake pipe of experimental cylinder, 8-exhaust pipe of experimental cylinder, 9-air intake valve, 10-exhaust gas analyzer , 11-second air filter, 12-intake pipe of other cylinders, 13-exhaust pipe of other cylinders, 14-exhaust gas turbocharger turbine, 15-direct injection fuel tank, 16-high pressure oil pump, 17-direct injection Fuel rail, 18-first cylinder direct injection injector, 19-high pressure gas tank, 20-pressure regulating valve, 21-accumulator, 22-accumulator outlet valve, 23-intake port injector , 24-intake air temperature sensor, 25-intake air pressure sensor, 26-exhaust gas temperature sensor, 27-exhaust pressure sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com