A kind of automobile glass with anti-reflection coating and its manufacturing method

A technology of anti-reflection coating and automotive glass, which is applied in the direction of coating, etc., can solve the problems that cannot be applied to automotive glass, etc., and achieve the effect of reducing energy consumption and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

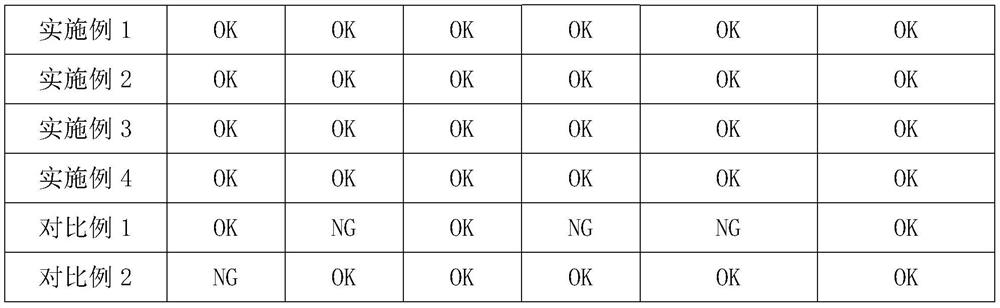

Examples

Embodiment 1

[0051] (1) Weigh tetraethyl orthosilicate, absolute ethanol, and 2,4-pentanedione with a molar ratio of 1:80:0.6 and mix and stir evenly under the action of a magnetic stirrer to obtain a mixed solution A;

[0052] (2) With the molar weight of tetraethyl orthosilicate being 1, weigh 10% nitric acid and deionized water with a molar ratio of 0.03:1, and mix and stir evenly under the action of a magnetic stirrer to obtain a mixed solution B ;

[0053] (3) Slowly drop the mixed solution B into the mixed solution A with a dropper, and continuously stir the mixed solution A during the dropping process until the two are completely mixed to obtain the solution C;

[0054] (4) Taking the molar weight of tetraethyl orthosilicate as 1, polyethylene glycol 1000 with a molar weight of 0.12 was added to the solution C, and after mixing and stirring for 6 hours, the solution D was obtained;

[0055] (5) Prepare at least one pretreated glass substrate, and dry it after ultrasonic cleaning; p...

Embodiment 2

[0058] (1) Weigh orthosilicate methyl ester, absolute ethanol, and 2,4-pentanedione with a molar ratio of 1:100:3 and mix and stir evenly under the action of a magnetic stirrer to obtain a mixed solution A;

[0059] (2) With the molar amount of methyl orthosilicate being 1, weigh 10% hydrochloric acid and deionized water with a molar ratio of 0.001:1, and mix and stir evenly under the action of a magnetic stirrer to obtain a mixed solution B ;

[0060] (3) Slowly drop the mixed solution B into the mixed solution A with a dropper, and continuously stir the mixed solution A during the dropping process until the two are completely mixed to obtain the solution C;

[0061] (4) With the molar weight of methyl orthosilicate being 1, polyethylene glycol 2000 with a molar weight of 0.5 was added to the solution C, and after mixing and stirring for 6 hours, the solution D was obtained;

[0062] (5) Prepare at least one pretreated glass substrate, and dry it after ultrasonic cleaning; p...

Embodiment 3

[0065] (1) Weigh tetraethyl orthosilicate, absolute ethanol, and methyl isoamyl ketone with a molar ratio of 1:80:0.6 and mix and stir evenly under the action of a magnetic stirrer to obtain a mixed solution A;

[0066] (2) With the molar weight of tetraethyl orthosilicate being 1, weigh nitric acid and deionized water with a molar ratio of 0.05:30 and a mass fraction of 10%, and mix and stir evenly under the action of a magnetic stirrer to obtain a mixed solution B ;

[0067] (3) Slowly drop the mixed solution B into the mixed solution A with a dropper, and continuously stir the mixed solution A during the dropping process until the two are completely mixed to obtain the solution C;

[0068] (4) Taking the molar weight of tetraethyl orthosilicate as 1, polyethylene glycol 2000 with a molar weight of 0.01 was added to the solution C, and after mixing and stirring for 6 hours, the solution D was obtained;

[0069] (5) Prepare at least one pretreated glass substrate, and dry it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com