Superfine powder flocculant for treating algae in eutrophic water body and preparation method thereof

An ultra-fine powder, nutrient-rich technology, used in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Poor stability and other problems, to achieve long-lasting algae removal effect, improve stability, and facilitate industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

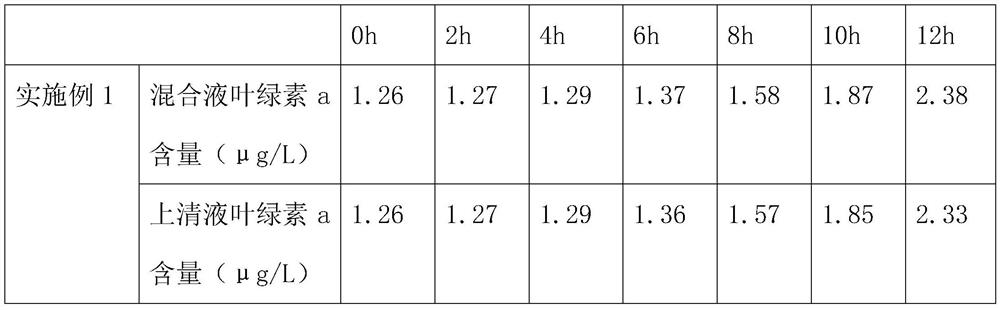

Embodiment 1

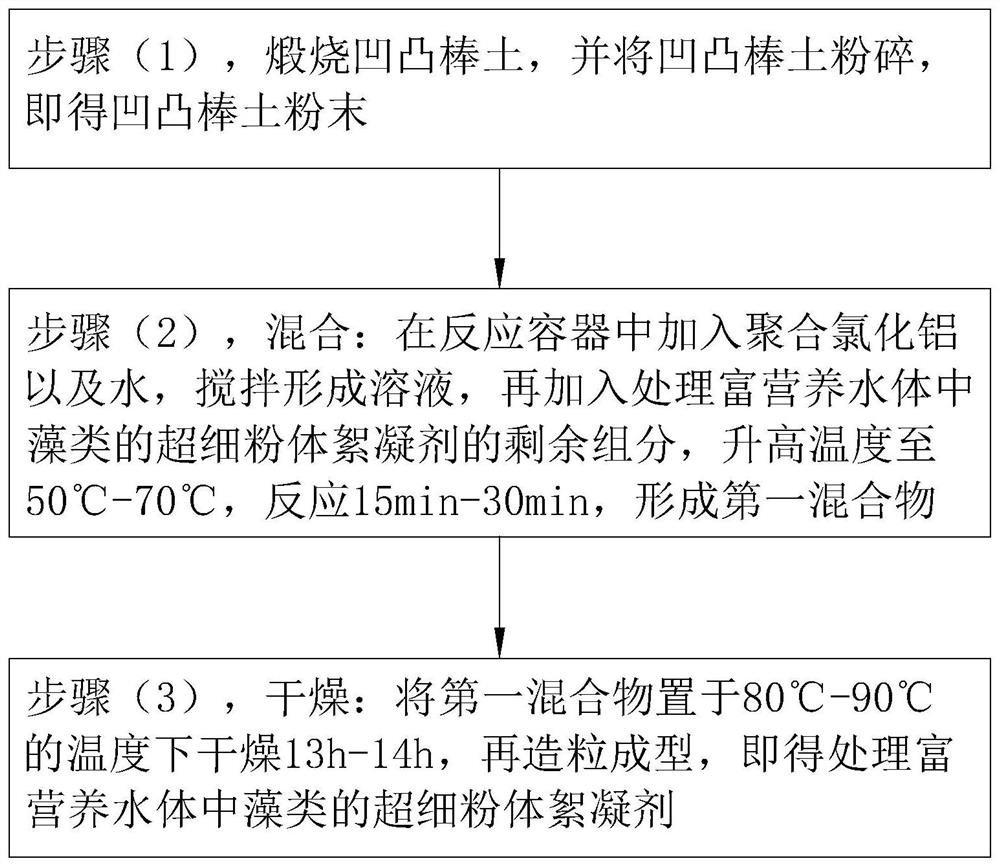

[0069] A method for preparing an ultrafine powder flocculant for treating algae in nutrient-rich waters, comprising the following steps:

[0070] Step (1), prepare attapulgite powder, specifically as follows:

[0071] Put the attapulgite in an industrial calcining kiln, and carry out calcination at a temperature of 450°C for 1.5 hours, then crush the attapulgite, pass through a 200-mesh sieve, and re-grind the attapulgite that cannot be sieved until all All the attapulgite powders pass through a 200-mesh sieve to obtain the attapulgite powder with a particle size less than or equal to 200 mesh.

[0072] Step (2), mixing, is as follows:

[0073] Add 30kg of polyaluminum chloride and 20kg of water into a 100L stirred tank, and stir at a speed of 240r / min to dissolve the polyaluminum chloride to form a solution, then add the attapulgite powder prepared in step (1) while stirring 5kg, 3kg of resveratrol, 1kg of lauryl methacrylate, and 1.5kg of silicone oil were stirred and mixe...

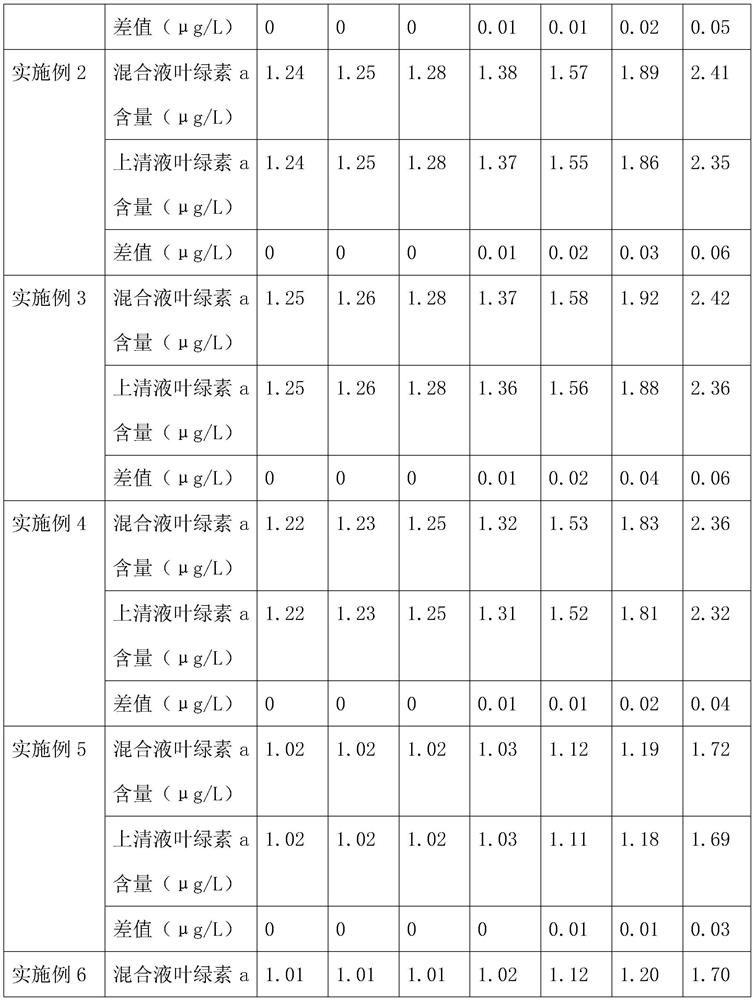

Embodiment 2

[0077] The difference with embodiment 1 is:

[0078] Step (2), mixing, is as follows:

[0079] Add 35kg of polyaluminum chloride and 17.5kg of water into a 100L stirred tank, and stir at a speed of 240r / min to dissolve the polyaluminum chloride to form a solution, then add the attapulgite obtained in step (1) while stirring 4kg of powder, 2kg of resveratrol, 0.5kg of lauryl methacrylate, and 1.25kg of silicone oil were stirred and mixed evenly, then the temperature was raised to 60°C, and the mixture was reacted for 23 minutes to form the first mixture.

[0080] The drying temperature in step (3) is 85° C., and the drying time is 13.5 hours.

Embodiment 3

[0082] The difference with embodiment 1 is:

[0083] Step (2), mixing, is as follows:

[0084] Add 40kg of polyaluminum chloride and 15kg of water into a 100L stirred tank, and stir at a speed of 240r / min to dissolve the polyaluminum chloride to form a solution, then add the attapulgite powder prepared in step (1) while stirring 3kg, 1kg of resveratrol, 0.75kg of lauryl methacrylate, and 1kg of silicone oil were stirred and mixed evenly, then the temperature was raised to 70° C., and reacted for 15 minutes to form the first mixture.

[0085] The drying temperature in step (3) is 90° C., and the drying time is 13 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com