Surface treatment method for stripping single crystal thin film through ion implantation

A single crystal thin film and ion implantation technology, which is applied in cleaning methods and appliances, chemical instruments and methods, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve problems such as changes in wettability of thin films, and achieve single crystal quality The effect of improving and simplifying complexity and reducing secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The surface treatment method of the ion implantation peeling single crystal thin film of the present embodiment comprises the following steps:

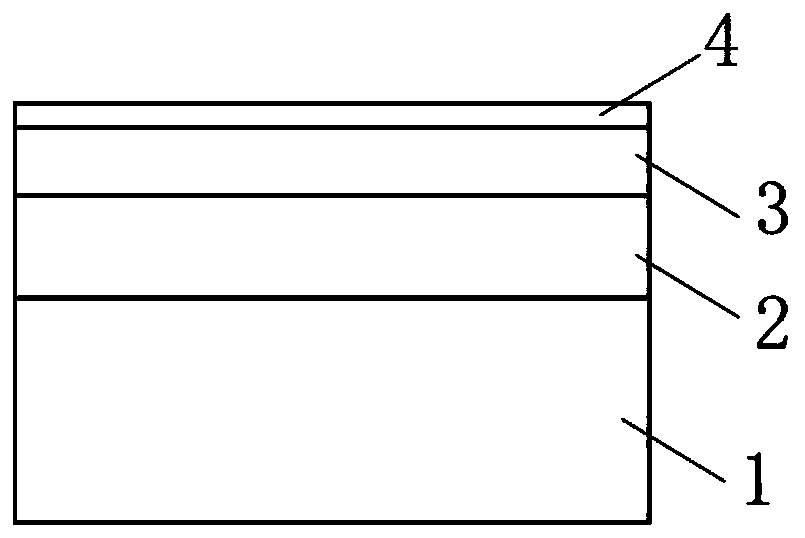

[0025] Such as figure 1 As shown, the single crystal piezoelectric thin film prepared by ion implantation stripping technology is processed, and the single crystal thin film includes a surface damage layer 4, a single crystal thin film layer 3, a bonding layer 2, and a substrate 1 from top to bottom;

[0026] Step 1. For the monocrystalline piezoelectric thin film prepared by ion implantation stripping technology, the surface damaged layer is accurately removed by argon ion etching method.

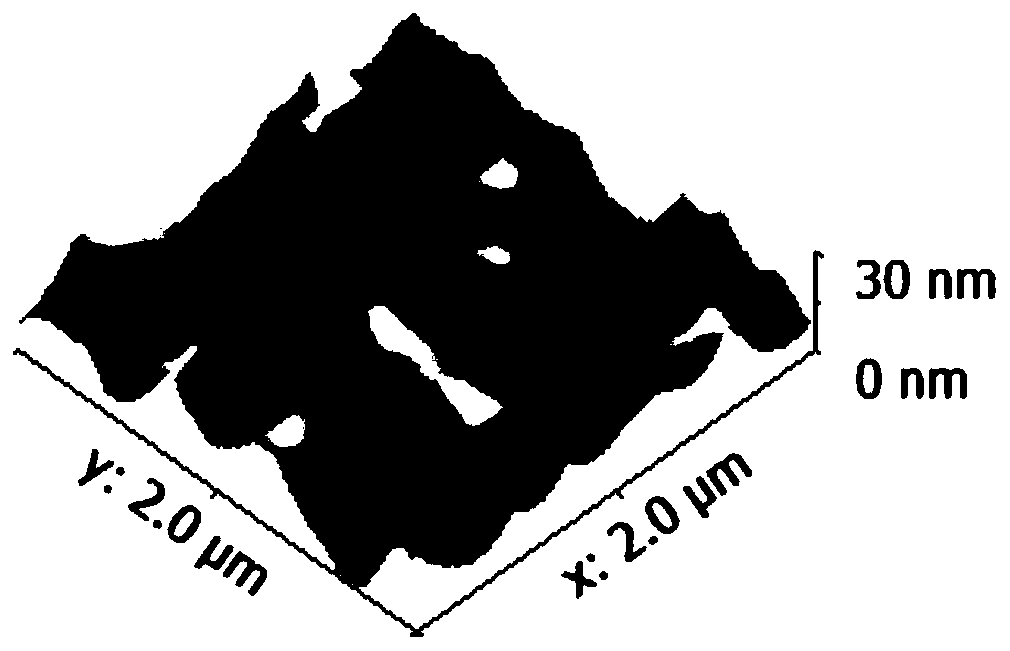

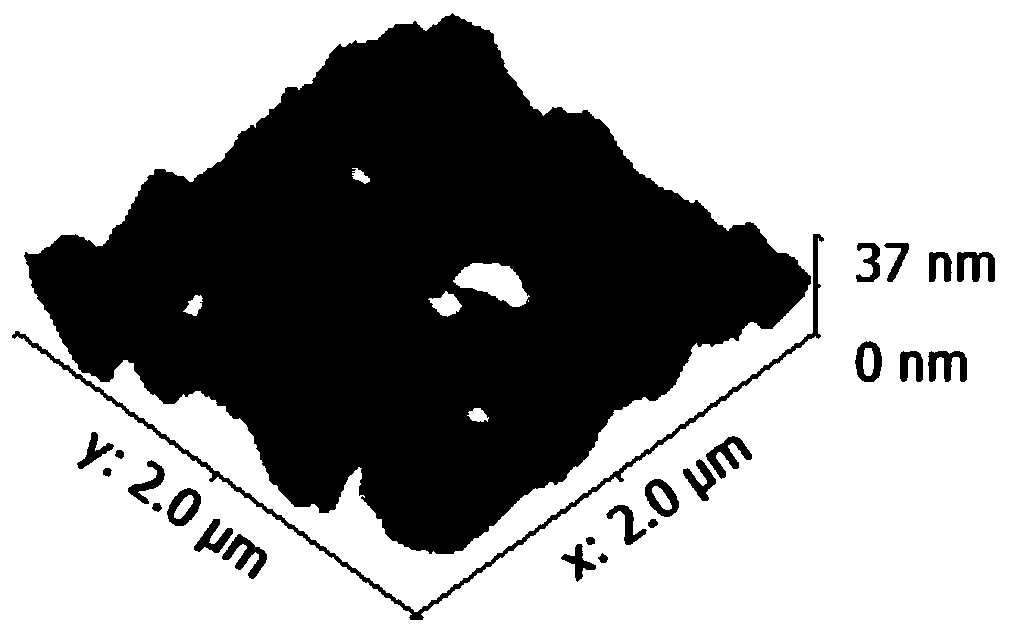

[0027] The single crystal film prepared by ion implantation stripping technology is placed in the working chamber of the ion source, the thickness of the surface damage layer is 100nm-130nm, the beam voltage is set to 200V-500V, the beam current is 4mA-30mA, and the accelerating voltage is 40V-100V; the thickness range of the surface damag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com